Low-melting-point high-volume latent heat phase change thermal storage material and preparation method and application thereof

A phase-change heat storage, high-volume technology, applied in heat exchange materials, chemical instruments and methods, etc., to achieve the effects of stable physical and chemical properties, low volume change rate, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

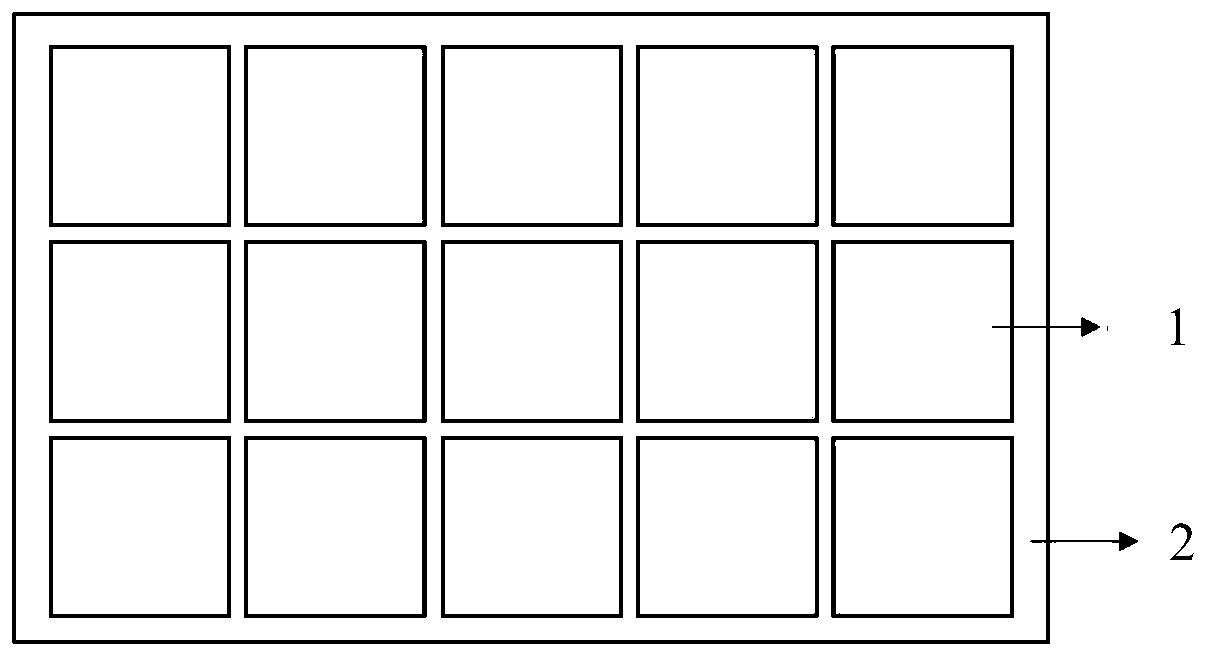

[0033] A phase change heat storage material with low melting point and high volume latent heat, which is composed of In, Bi, Sn, Zn, and Ga, and the ratio of each component is: In: 12%, Bi: 80%, Sn: 6.5%, Zn: 1 %, Ga: 0.5%. Carry out vacuum melting and casting according to the recipe, the melting temperature is 415±5°C, and after standing at 340±5°C for 3 minutes, cast into an ingot of 20×100×200mm. Sampling test shows that its melting point is between 110 and 130°C, and its volume latent heat is 491J / cm 3 , The thermal conductivity is 12W / mK. The surface of the billet was milled to a thickness of 18 mm, and rolled to 14 mm at room temperature. Wire-cut and face-mill the rolled billet to prepare a 12×20×20mm block material, which is filled into the 6061 aluminum alloy shell with a size interference of 3%. Such as figure 1 Shown is a schematic diagram of a low-melting point phase-change heat storage alloy packaged in an aluminum alloy shell.

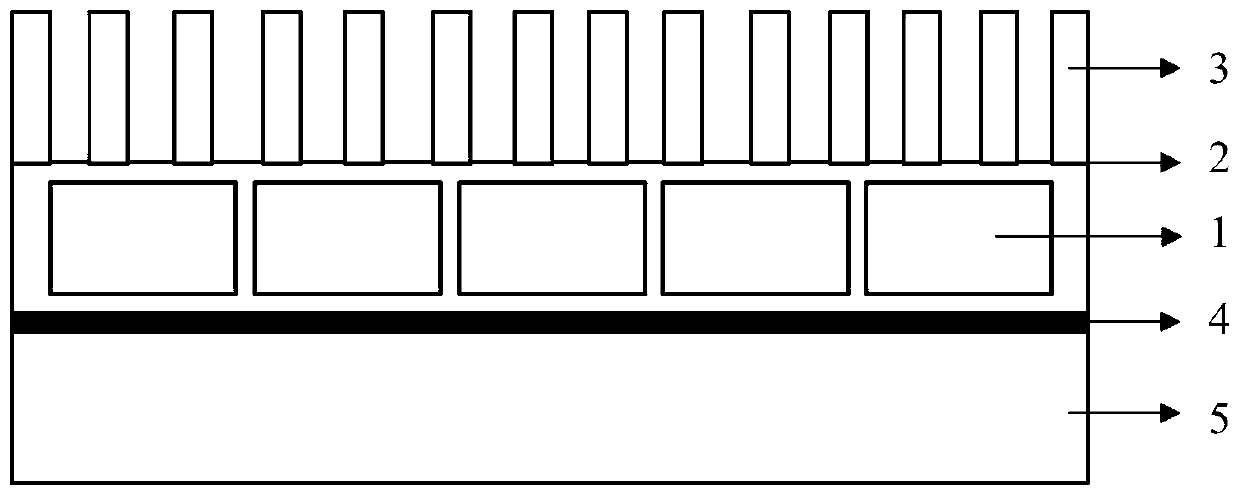

[0034] Such as figure 2 As ...

Embodiment 2

[0036] A phase-change heat storage material with low melting point and high volume latent heat, which is composed of In, Bi, Sn, Zn, and Ga, and the ratio of each component is: In: 15%, Bi: 75%, Sn: 8.5%, Zn: 0.9 %, Ga: 0.6%. Carry out vacuum melting and casting according to the recipe, the melting temperature is 410±5°C, and after standing at 330±5°C for 3 minutes, downcast into an ingot of 20×100×200mm. Sampling and testing, its melting point is between 90 and 110°C, and its volume latent heat is 457J / cm 3 , The thermal conductivity is 14W / mK. The surface of the billet was milled to a thickness of 18 mm, and rolled to 14 mm at room temperature. Wire-cut and face-mill the rolled billet to prepare a 12×20×20mm block material, which is filled into the 7075 aluminum alloy shell with a size interference of 2%. Such as figure 1Shown is a schematic diagram of a low-melting point phase-change heat storage alloy packaged in an aluminum alloy shell.

[0037] Such as figure 2 As...

Embodiment 3

[0039] A phase change heat storage material with low melting point and high volume latent heat, which is composed of In, Bi, Sn, Zn, and Ga, and the ratio of each component is: In: 18%, Bi: 70%, Sn: 9%, Zn: 2.6 %, Ga: 0.4%. Carry out vacuum melting and casting according to the recipe, the melting temperature is 405±5°C, and after standing at 320±5°C for 3 minutes, down-cast into an ingot of 20×100×200mm. Sampling and testing, its melting point is between 70 and 90°C, and its volume latent heat is 393J / cm 3 , The thermal conductivity is 18W / mK. The surface of the billet was milled to a thickness of 18 mm, and rolled to 14 mm at room temperature. Wire-cut and face-mill the rolled billet to prepare a 12×20×20mm block material, which is filled into the 2024 aluminum alloy shell with a size interference of 1%. Such as figure 1 Shown is a schematic diagram of a low-melting point phase-change heat storage alloy packaged in an aluminum alloy shell.

[0040] Such as figure 2 As ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com