Alcohol-based liquid fuel

A liquid fuel, alcohol-based technology, used in liquid carbon-containing fuels, fuels, petroleum industries, etc., can solve problems such as damage to combustion equipment and excessive pollutants, and achieve the effect of reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

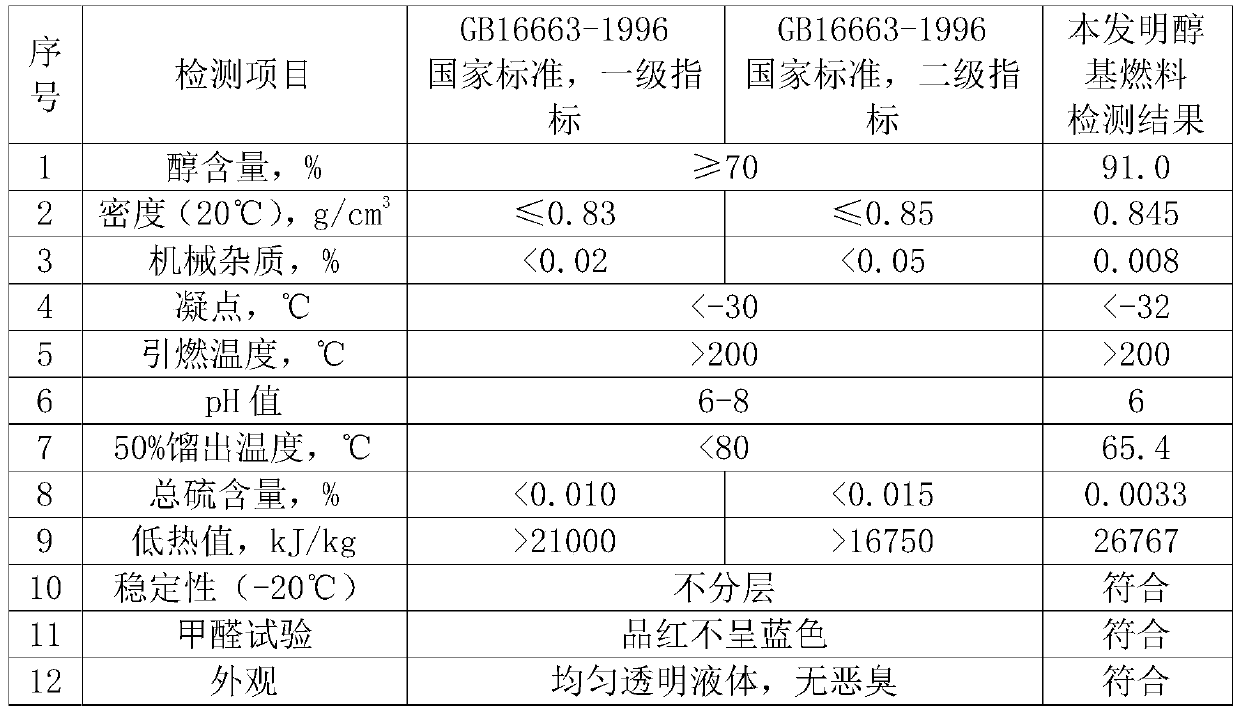

Image

Examples

Embodiment 1

[0020] A kind of alcohol base liquid fuel, its composition and weight percent are as follows:

[0021] 85% low carbon alcohol, 3.5% polycarbonate alcohol, 0.5% aliphatic ether, 11% hydrocarbon compound, 0.05% external additive;

[0022] The low-carbon alcohol is methanol, the multi-carbon alcohol is n-butanol, the aliphatic ether is ethyl propyl ether, the hydrocarbon compound is solvent oil, and the additive components and weight percentages are as follows: including 70% of nitrogen-containing compounds and 15% of esters 15% of phenolic antioxidant, wherein the nitrogen-containing compound is 70% of diethylenetriamine, the ester is 15% of ethyl acetate, and the phenolic antioxidant is 15% of 2,6-di-tert-butyl mixed phenol;

[0023] The method of use is: according to the proportion and order of the above formula, feed materials into the blending tank respectively, and blend for 30 minutes at normal temperature and pressure;

[0024] The preparation method of the external addi...

Embodiment 2

[0026] A kind of alcohol base liquid fuel, its composition and weight percent are as follows:

[0027] 95% of low-carbon alcohols, 2.5% of polycarbonate alcohols, 0.5% of aliphatic ethers, 2% of hydrocarbon compounds, and 0.07% of external additives;

[0028] The low-carbon alcohol is ethanol, the multi-carbon alcohol is isooctyl alcohol, the aliphatic ether is methyl tert-amyl ether, and the hydrocarbon compound is washing oil. %, 10% phenolic antioxidant, of which the nitrogen-containing compound is triethylenetetramine 75%, the ester is 15% butyl acetate, and the phenolic antioxidant is 2,8-di-tert-butyl-4-methyl Phenol 10%;

[0029] The method of use is: according to the proportion and order of the above formula, feed the ingredients into the blending tank respectively, and blend for 60 minutes at normal temperature and pressure;

[0030] The preparation method of the external additives is as follows: according to the above-mentioned formula ratio and sequence, the mater...

Embodiment 3

[0032] A kind of alcohol base liquid fuel, its composition and weight percent are as follows:

[0033] 90% low-carbon alcohol, 3% polycarbonate alcohol, 0.5% aliphatic ether, 6.5% hydrocarbon compound, 0.07% external additive;

[0034] Low-carbon alcohol is a mixture of 70% by weight methanol and 30% ethanol, multi-carbon alcohol is isoamyl alcohol, aliphatic ether is propyl amyl ether, and hydrocarbon compound is straight-run oil; the additive components and weight percentages are as follows: Including 70% of nitrogen-containing compounds, 15% of esters, and 15% of phenolic antioxidants, of which 70% of nitrogen-containing compounds are tetraethylenepentamine, 15% of esters are ethyl lactate, and phenolic antioxidants are 2-methyl Base-6-tert-butylphenol 15%,

[0035] The method of use is: according to the proportion and order of the above formula, feed the ingredients into the blending tank respectively, and blend for 60 minutes at normal temperature and pressure;

[0036]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com