Preparation method and preparation device of polylysine

A polylysine and preparation device technology, applied in the field of polylysine preparation method and its preparation device, can solve problems such as human side effects, and achieve the effect of easy control and regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 of the present invention relates to a preparation method of polylysine, which includes the following steps: seed selection, expanded cultivation, fermentation preparation, and filtration and clarification;

[0025] The specific implementation method of the seed selection step is: select the mixed strain of Streptomyces albicans and ergot fungus as the polylysine strain.

[0026] The specific implementation method of the expanded cultivation step is: under aseptic conditions, transplant the selected polylysine strain into a prepared petri dish for cultivation, and the petri dish uses glucose as a carbon source and peptone as a nitrogen source , formulated with inorganic salts and growth factors; the polylysine strains are carried out on the petri dish for 3 to 5 times, and the maintenance time of each expansion culture is 4 to 6 days; the temperature of each expansion culture is controlled at 23 to 29 ° C, The cultivation humidity was kept at 60-65%.

[002...

Embodiment 2

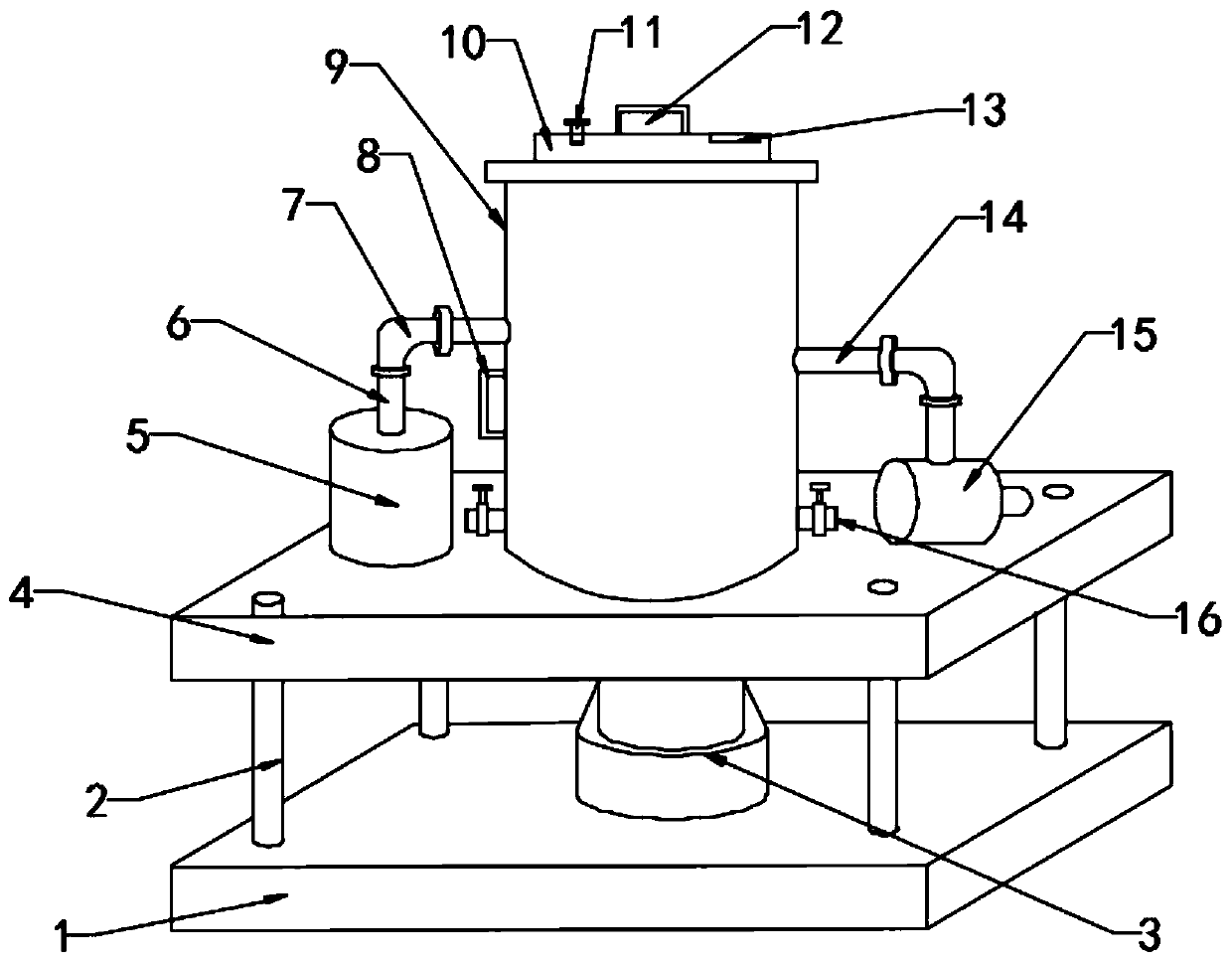

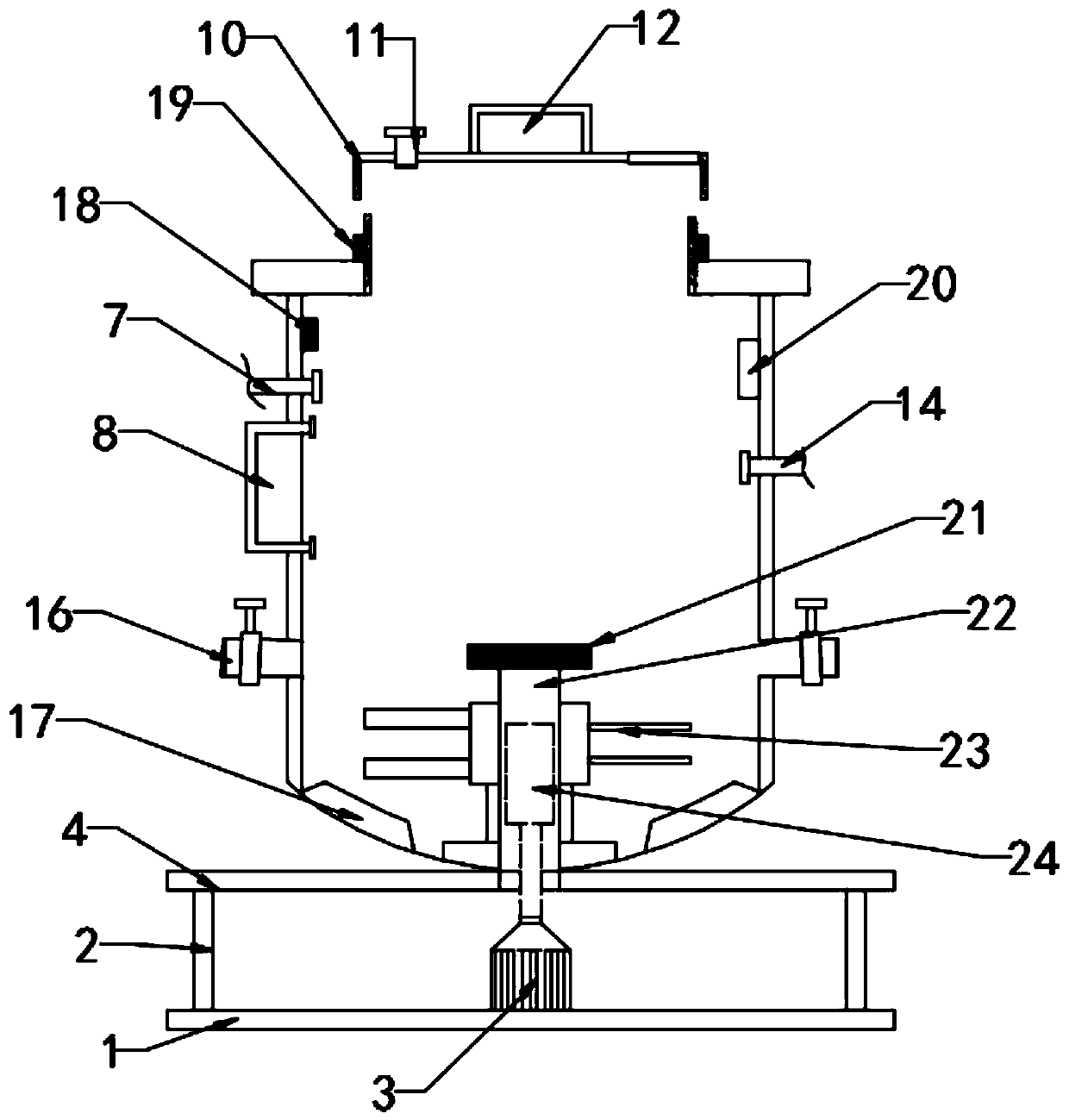

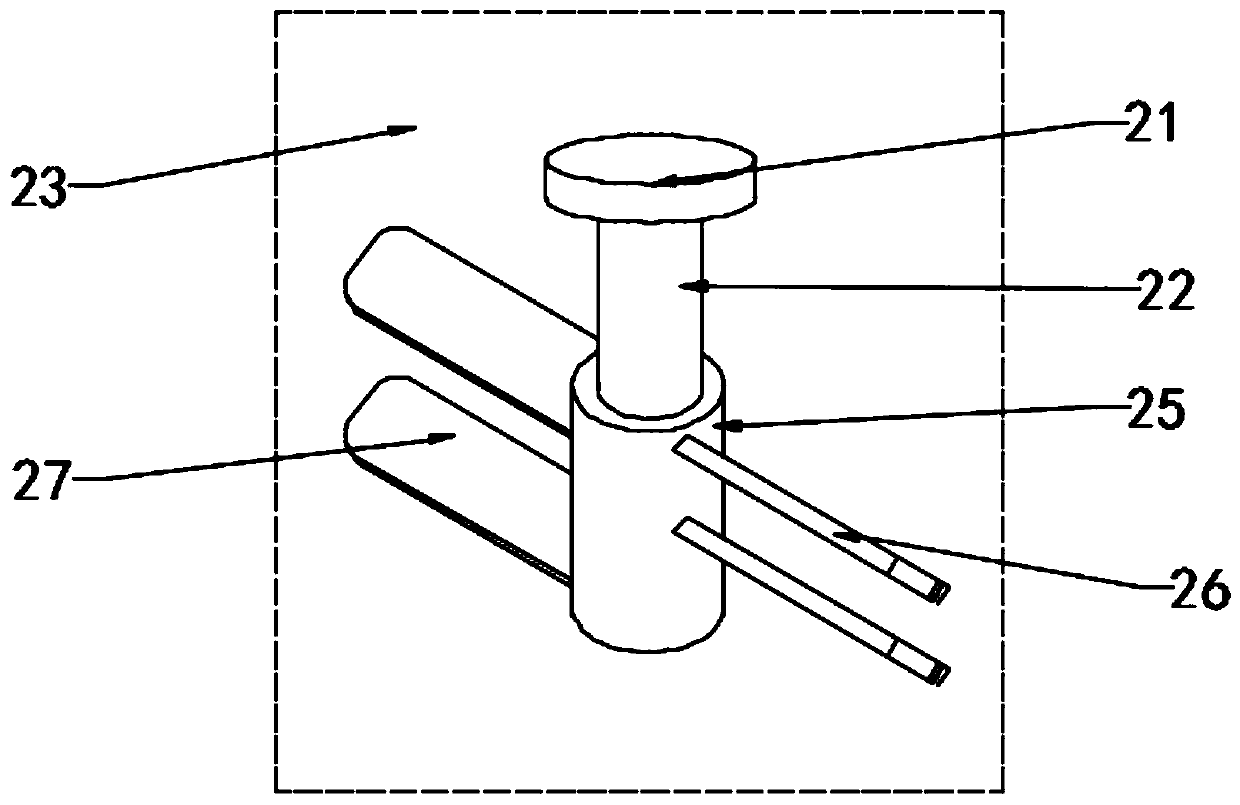

[0030] see Figure 1~2 , in Embodiment 2 of the present invention, a preparation device related to the preparation method of polylysine in Embodiment 1 is provided, which includes: a preparation device body 9, a sealing cover 10 is installed on the upper end of the preparation device body 9, and the preparation The left side of the device body 9 is provided with an oxygen supply pipe 6 and a liquid level gauge 8, and the oxygen supply pipe 6 is connected through a two-way pipe 7, and the preparation device body 9 is connected to the oxygen tank 5 through the oxygen supply pipe 6; the preparation device body 9 The right side is connected to the booster pump 15 through the booster pipe 14; the left and right sides of the lower end of the preparation device body 9 are provided with a discharge pipe 16, and the discharge pipe 16 is provided with a discharge valve, and the bottom end of the preparation device body 9 is installed and fixed on the working on stage 4;

[0031] A ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com