Surface hardening treatment method for metal stamping die

A technology of hardening treatment and metal stamping, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve problems affecting production and processing efficiency, impact of wear resistance and hardness, and increase maintenance frequency, etc., to achieve Eliminate repeated mold unloading, good lubricity, and reduce the frequency of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

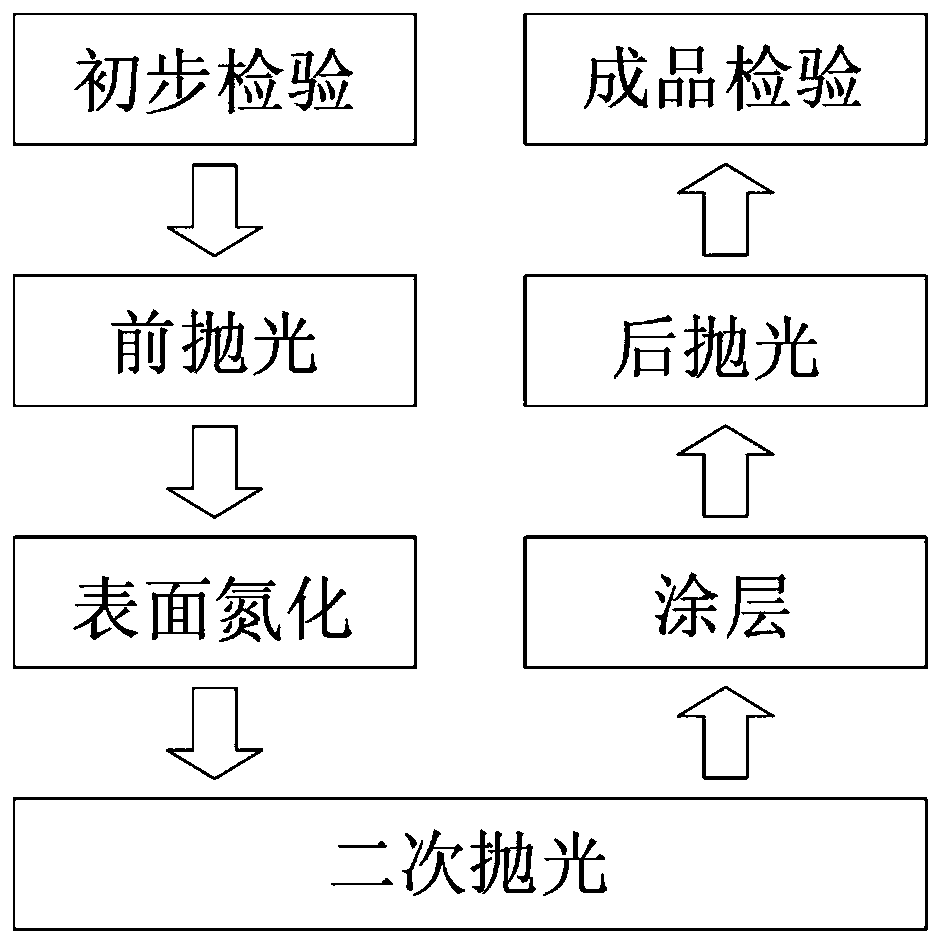

[0044] The invention discloses a surface hardening treatment method for metal stamping dies. figure 1 shown, including the following steps:

[0045] S1. Preliminary inspection

[0046] Preliminary inspection of whether the metal stamping dies to be treated meet the requirements of surface hardening treatment;

[0047] Wherein, the material type of the metal stamping die includes die steel, structural steel with a carbon content greater than 0.3%, cast iron and hard alloy.

[0048] S2, front polishing

[0049] Polish the surface of the metal mold that meets the requirements of the preliminary inspection, and remove the foreign matter and / or impurities adhered to the surface;

[0050] S3, surface nitriding

[0051] Nitriding the metal mold surface also includes the following sub-steps:

[0052] S31, degreasing the surface of the metal mold in S2 using a gas degreasing method;

[0053] S32, placing the metal mold treated in S31 in a nitriding furnace, sealing the furnace co...

Embodiment 2

[0073] The invention discloses a surface hardening treatment method for metal stamping dies. figure 1 shown, including the following steps:

[0074] S1. Preliminary inspection

[0075] Preliminary inspection of whether the metal stamping dies to be treated meet the requirements of surface hardening treatment;

[0076] Wherein, the material type of the metal stamping die includes die steel, structural steel with a carbon content greater than 0.3%, cast iron and hard alloy.

[0077] S2, front polishing

[0078] Polish the surface of the metal mold that meets the requirements of the preliminary inspection, and remove the foreign matter and / or impurities adhered to the surface;

[0079] S3, surface nitriding

[0080] Nitriding the metal mold surface also includes the following sub-steps:

[0081] S31, degreasing the surface of the metal mold in S2 using a gas degreasing method;

[0082] S32, placing the metal mold treated in S31 in a nitriding furnace, sealing the furnace co...

Embodiment 3

[0103] The invention discloses a surface hardening treatment method for metal stamping dies. figure 1 shown, including the following steps:

[0104] S1. Preliminary inspection

[0105] Preliminary inspection of whether the metal stamping dies to be treated meet the requirements of surface hardening treatment;

[0106] Wherein, the material type of the metal stamping die includes die steel, structural steel with a carbon content greater than 0.3%, cast iron and hard alloy.

[0107] S2, front polishing

[0108] Polish the surface of the metal mold that meets the requirements of the preliminary inspection, and remove the foreign matter and / or impurities adhered to the surface;

[0109] S3, surface nitriding

[0110] Nitriding the metal mold surface also includes the following sub-steps:

[0111] S31, degreasing the surface of the metal mold in S2 using a gas degreasing method;

[0112] S32, placing the metal mold treated in S31 in a nitriding furnace, sealing the furnace co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com