Enzyme removing and oxygen bleaching combined degumming process for ramie

A technology of ramie enzyme and oxygen bleaching, which is applied in the direction of producing bast fiber by chemical method, can solve the problems of cumbersome degumming method, high energy consumption, long degumming cycle, etc., and achieve good degumming effect, low cost and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

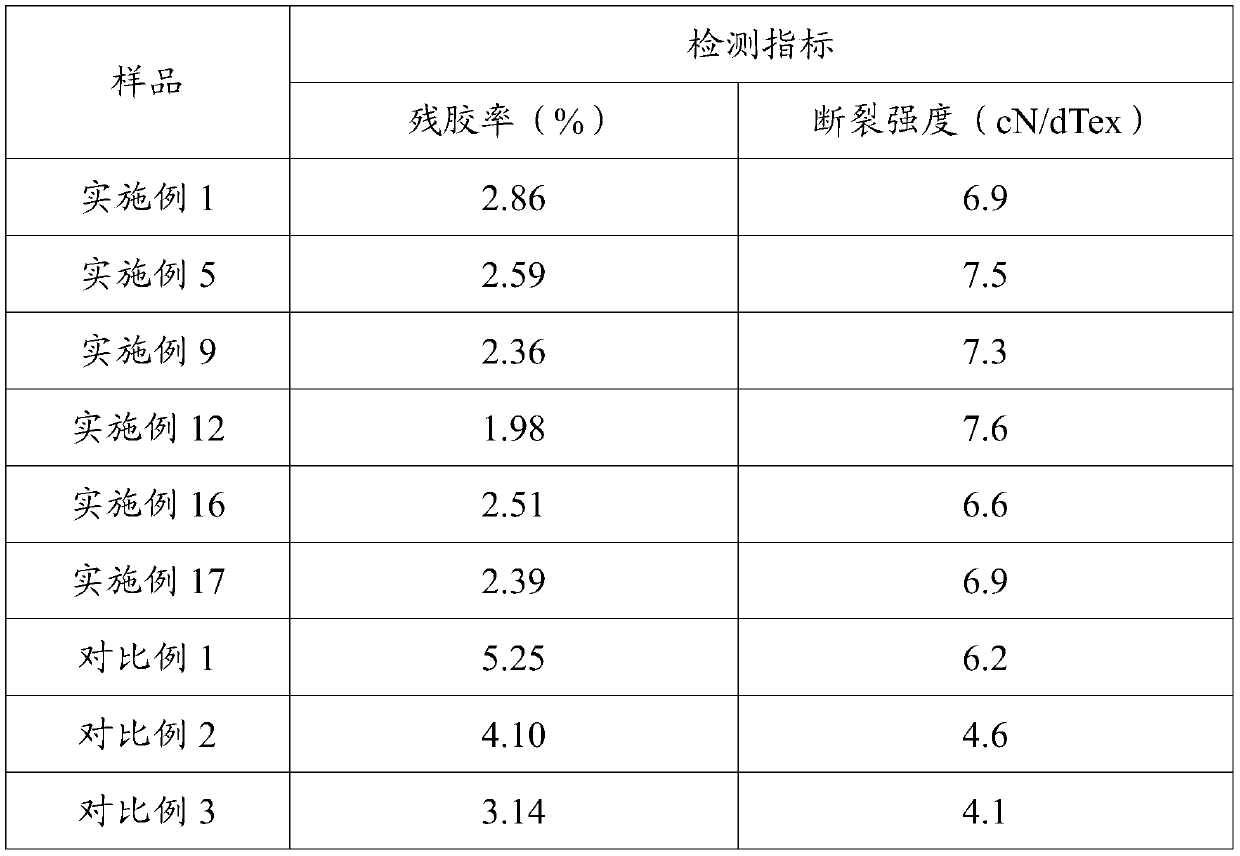

Examples

Embodiment 1

[0035] A kind of ramie enzyme de-oxygen bleaching combined degumming process, comprises the steps:

[0036] S1 chops and cuts the bast of the root of raw hemp, puts the original hemp into the first soaking liquid and soaks it, puts it into a softening machine after soaking for mechanical processing; the first soaking liquid is an aqueous ethanol solution with a mass fraction of 18%, and the ratio of solid to liquid is 1: 10. The soaking temperature is 50°C, and the soaking time is 12 minutes.

[0037] S2 Add the softened raw hemp in S1 to the acidic enzyme preparation solution for soaking; use oxalic acid to adjust the pH to 4.0-5.0, the ratio of solid to liquid is 1:8, the soaking time is 12 hours, and the soaking temperature is 50°C. Based on the weight percentage of raw hemp, the acid enzyme preparation includes 1.5% compound enzyme and 0.2% degumming aid. The ratio of each component of the acid enzyme preparation is acid pectinase:acid ligninase=1:1:2, and the degumming a...

Embodiment 2

[0041] Compared with Example 1, the present embodiment differs in that the degumming aid is different.

[0042] In this embodiment, the degumming aid is sodium tripolyphosphate.

Embodiment 3

[0044] Compared with Example 1, the present embodiment differs in that the degumming aid is different.

[0045] In this embodiment, the degumming aid is sodium metasilicate.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap