A flue gas cooler applied to mobile medical waste treatment system

A technology of waste treatment system and flue gas cooler, which is applied in the direction of indirect heat exchanger, heat exchanger type, heat exchanger shell, etc., can solve the problem that the medical waste incineration system cannot be applied, the system has high fuel consumption and power consumption, and there is no way Energy and other issues, to achieve the effect of compact structure, reduce system fuel consumption and power consumption, and avoid sudden increase of smoke volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

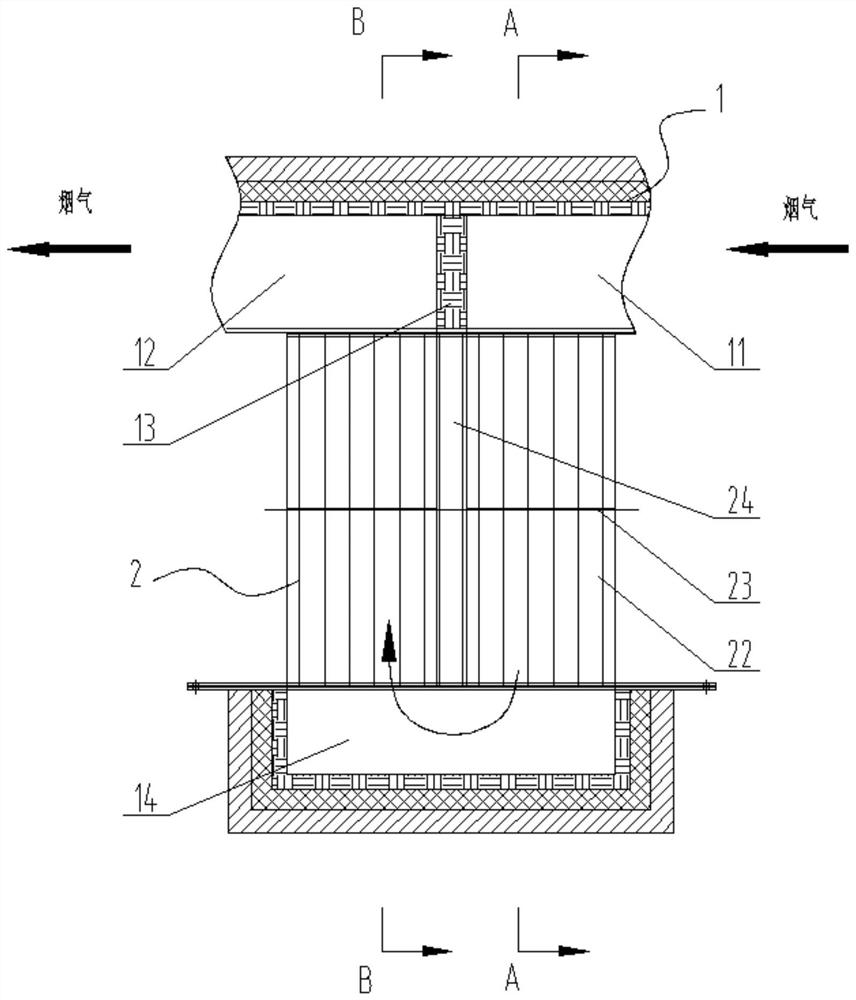

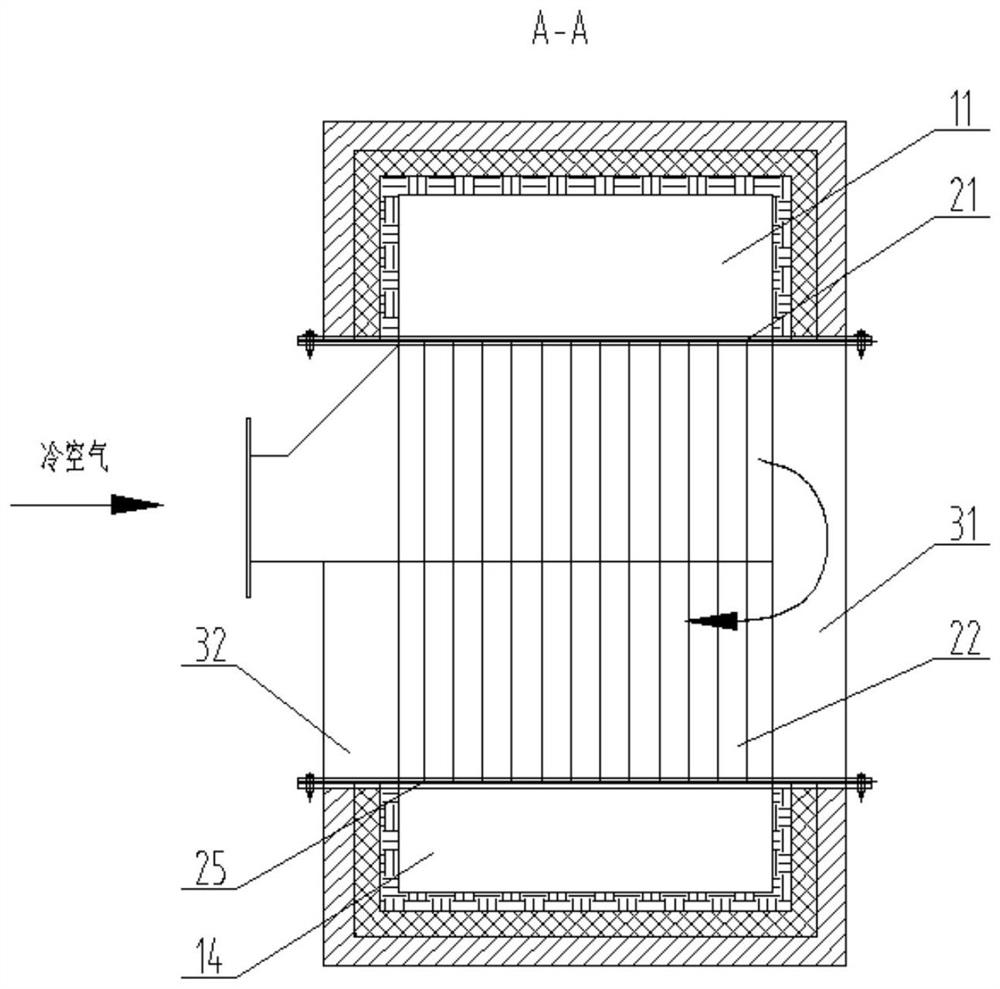

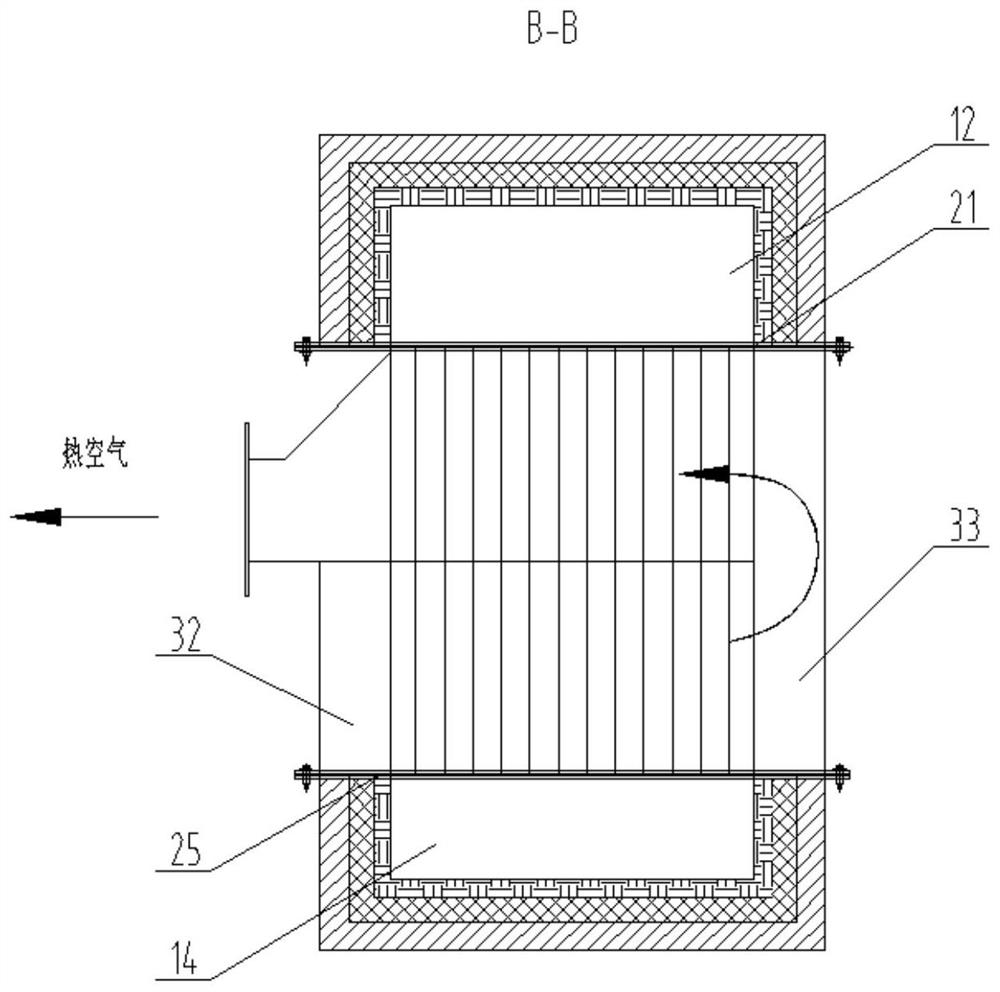

[0022] like figure 1 and Figure 4 As shown, the present invention is a flue gas cooler applied to a mobile medical waste treatment system, including: a flue 1 and a heat exchange tube box 2, the heat exchange tube box 2 is installed in the flue 1, for the convenience of later For maintenance and replacement, the heat exchange tube box 2 and the flue 1 are connected by bolts.

[0023] In order to improve the heat exchange efficiency of the flue gas cooler and improve the structural compactness of the flue gas cooler, the heat exchange tube box 2 is provided with at least two flue gas passages and no less than two single air ventilation chambers , this embodiment takes two flue gas return trips, four air return trips, the flue inlet and flue outlet on the same side, and the heat exchange tube box air inlet and air outlet on the same side as examples. The specific number of return trips can be adjusted according to needs In addition, the layout of the flue inlet and flue outle...

Embodiment 2

[0033] The difference between embodiment 2 and embodiment 1 is that the flue gas in embodiment 1 is changed to flow outside the smoke pipe 22 , while the air is changed to flow inside the smoke pipe 22 .

[0034] work process:

[0035] Flue gas flow

[0036]High-temperature incineration produces high-temperature flue gas of about 1000°C flowing along the flue 1, entering the heat exchange tube box 2 from the flue inlet 11 through the flue pipe 22, and the high-temperature flue gas flows through the flue gas first return, The flue gas is connected to the cavity 14 and the second return of the flue gas. After the flue gas undergoes two return heat exchanges, the temperature of the high-temperature flue gas drops to about 600° C., and finally enters the downstream equipment through the flue outlet 12 .

[0037] air flow

[0038] The cold air is entered by the blower through the air inlet of the heat exchange tube box 2, and the cold air passes through the first air return, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com