Cold dry method online analysis sample gas treatment system

A sample gas processing system and sample gas technology, applied in the field of flue gas online monitoring, can solve problems such as interference, reduce transmission resistance, ensure filtering effect, and achieve the effect of true measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

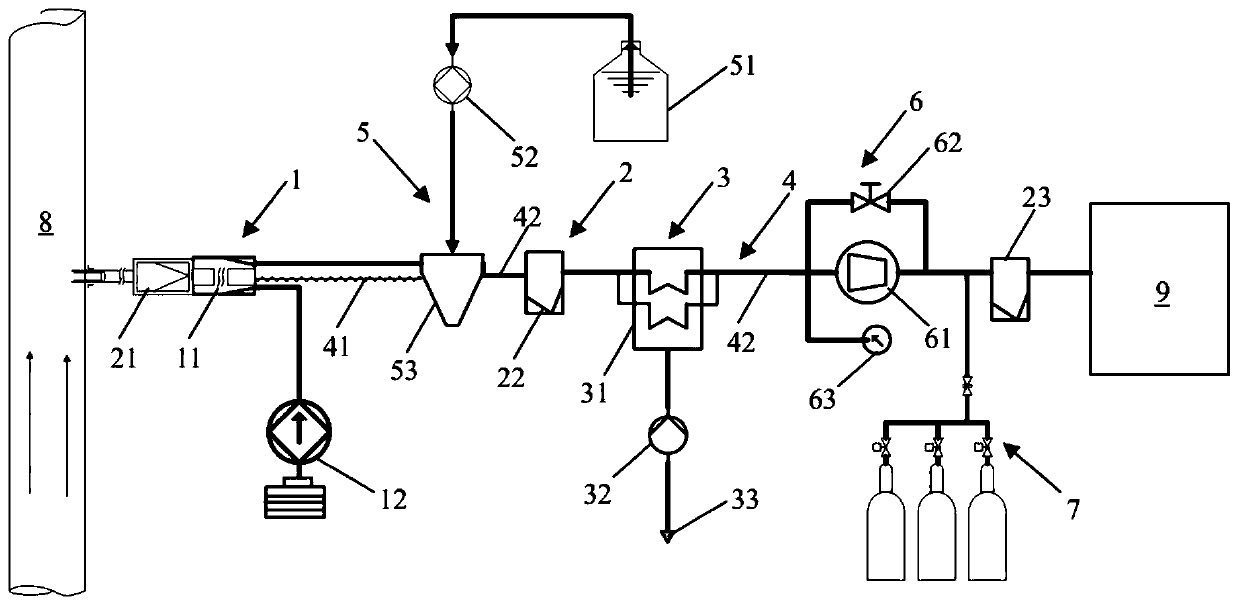

[0027] figure 1 It is a schematic structural diagram of the cold-drying method sample gas treatment system provided in Example 1 of the present invention. Such as figure 1 As shown, the cold-dry online analysis sample gas processing system provided by the present invention includes a sampling unit 1 connected through a sample gas pipeline 4, a sample gas processing unit and a sample gas control unit 3, and the sample gas control unit 3 is configured to monitor And control the sample gas flow rate and sample gas temperature of the sample gas processing system; the sample gas processing unit includes a dust removal device 2 and a dehumidification device 3, and a phosphoric acid introduction unit 5 is arranged upstream of the dehumidification device 2 according to the flow direction of the sample gas The phosphoric acid introduction unit 5 includes a first container 51 containing phosphoric acid and a vaporization device 53 connected to the first container 51 through a first mic...

Embodiment 2

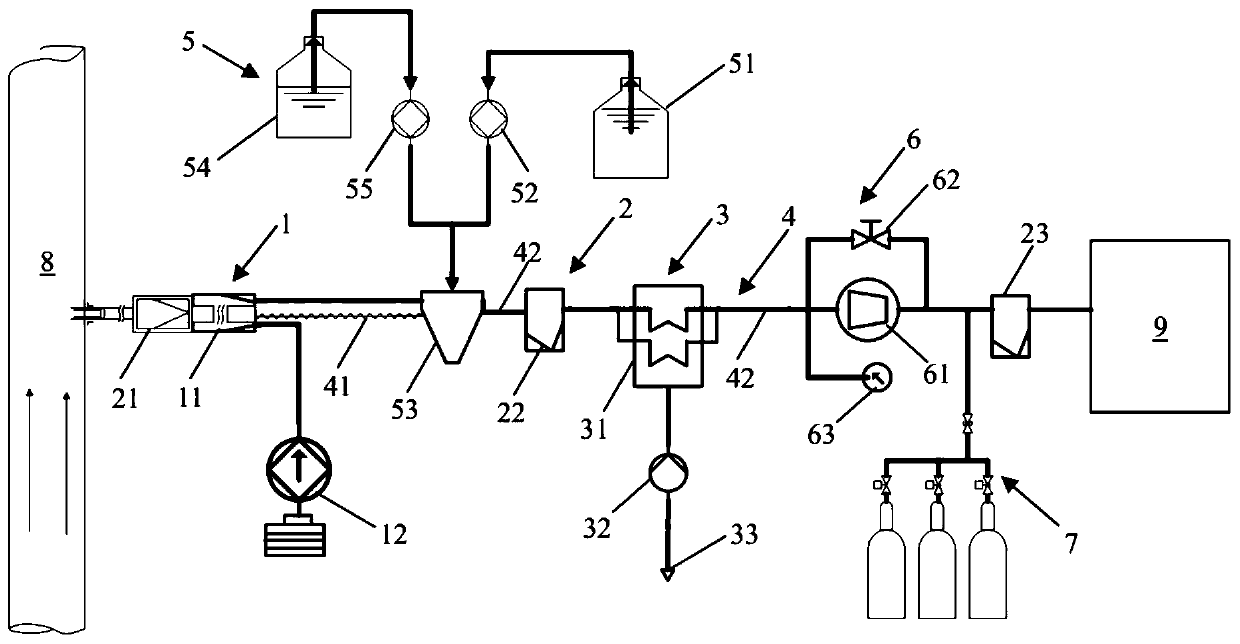

[0038] figure 2 It is a schematic structural diagram of the cold-drying method sample gas treatment system provided in Example 2 of the present invention. The sample gas processing system in embodiment 2 is similar in structure to the sample gas processing system in embodiment 1. The difference is that, in this embodiment, the phosphoric acid introducing unit 5 includes a first container 51 containing standard phosphoric acid and a vaporization device 53 connected to the first container 51 through a first micropump 52. In addition, the phosphoric acid introducing unit 5 also includes a container containing A second container 54 of water and a second micropump 55 , the second container 54 is connected to the vaporizer 53 through the second micropump 55 . The phosphoric acid introduction unit 5 of this embodiment can realize 2 When the concentration of the gas is equal, phosphoric acid of different concentrations is added dropwise to the sample gas treatment system. For exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com