Extraction method of flaxseed extract

A technology of flaxseed extract and extraction method, which is applied in the field of extraction of flaxseed extract, can solve problems such as the limitation of comprehensive development and utilization of nutritional active ingredients of flax and affect the development of flax industry, and achieve the effect of high material utilization efficiency and rich variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

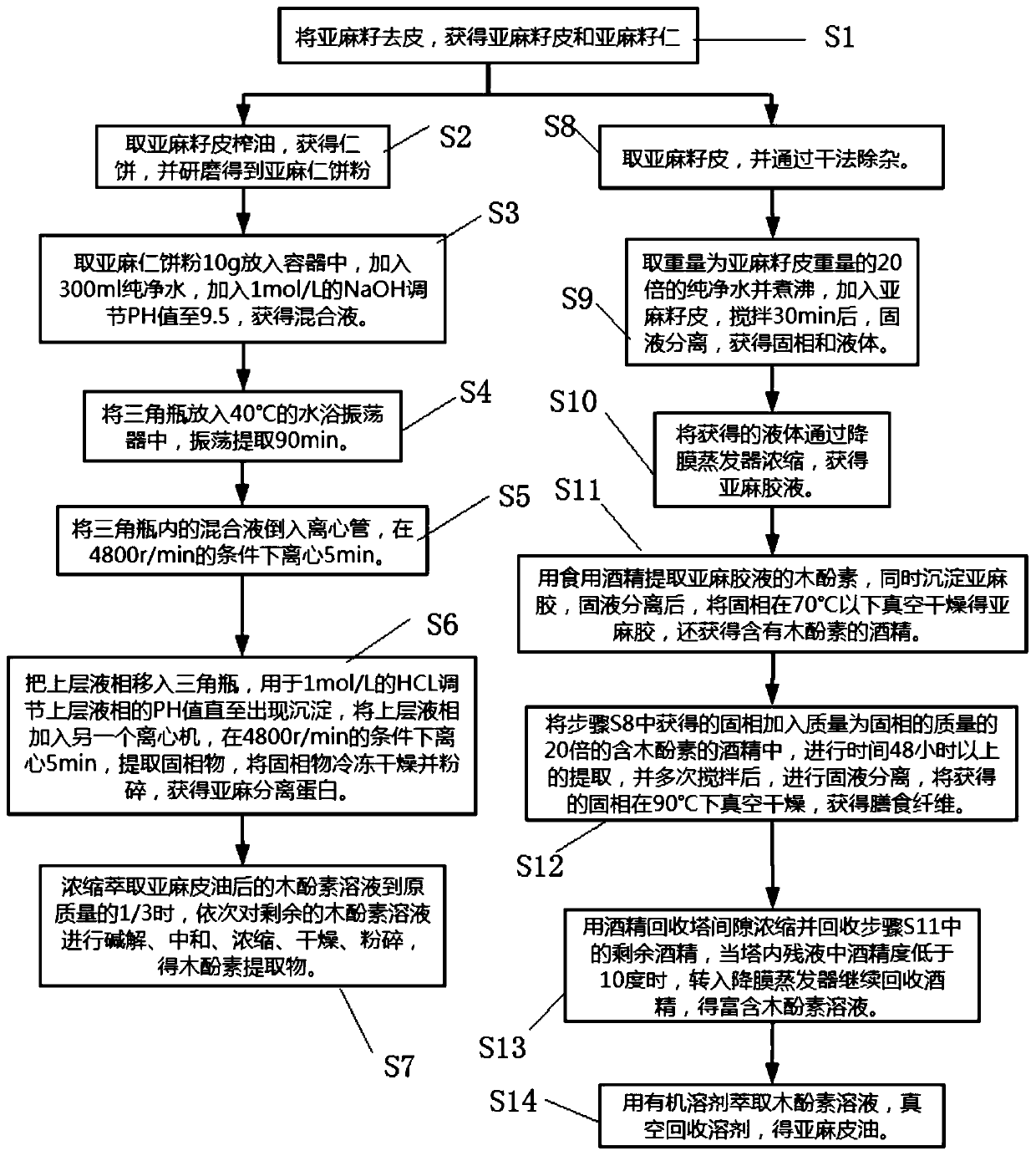

[0030] see figure 1 , the present embodiment provides a technical solution: a method for extracting linseed extract, comprising the following steps:

[0031] S1. Peel the linseed to obtain linseed skin and linseed kernel.

[0032] S2. Extract oil from linseed skin to obtain linseed cake, and grind it to obtain linseed cake powder.

[0033] S3. Put 10 g of linseed cake powder into a container, add 300 ml of pure water, and add 1 mol / L NaOH to adjust the pH value to 9.5 to obtain a mixed solution.

[0034] S4. Put the triangular flask into a water bath shaker at 40° C., shake and extract for 90 minutes.

[0035] S5. Pour the mixed solution in the Erlenmeyer flask into a centrifuge tube, and centrifuge at 4800 r / min for 5 min.

[0036] S6, move the upper layer liquid phase into the Erlenmeyer flask, use 1mol / L HCL to adjust the pH value of the upper layer liquid phase until precipitation occurs, add the upper layer liquid phase to another centrifuge, centrifuge at 4800r / min fo...

Embodiment 2

[0047] The present embodiment provides a technical solution: a method for extracting linseed extract, comprising the following steps:

[0048] S1. Peel the linseed to obtain linseed skin and linseed kernel.

[0049] S2. Extract oil from linseed skin to obtain linseed cake, and grind it to obtain linseed cake powder.

[0050] S3. Put 10 g of linseed cake powder into a container, add 250 ml of pure water, and add 1 mol / L NaOH to adjust the pH value to 9.0 to obtain a mixed solution.

[0051] S4. Put the triangular flask into a water bath shaker at 50° C., shake and extract for 135 minutes.

[0052] S5, pour the mixed solution in the Erlenmeyer flask into the centrifuge tube, and centrifuge for 5min under the condition of 4800r / min,

[0053] S6, move the upper layer liquid phase into the Erlenmeyer flask, use 1mol / L HCL to adjust the pH value of the upper layer liquid phase until precipitation occurs, add the upper layer liquid phase to another centrifuge, centrifuge for 5min u...

Embodiment 3

[0064] The present embodiment provides a technical solution: a method for extracting linseed extract, comprising the following steps:

[0065] S1. Peel the linseed to obtain linseed skin and linseed kernel.

[0066] S2. Extract oil from linseed skin to obtain linseed cake, and grind it to obtain linseed cake powder.

[0067] S3. Put 10 g of linseed cake powder into a container, add 300 ml of pure water, and add 1 mol / L NaOH to adjust the pH value to 9.5 to obtain a mixed solution.

[0068] S4. Put the triangular flask into a water bath shaker at 60° C., shake and extract for 150 minutes.

[0069] S5, pour the mixed solution in the Erlenmeyer flask into the centrifuge tube, and centrifuge for 5min under the condition of 4800r / min,

[0070] S6, move the upper layer liquid phase into the Erlenmeyer flask, use 1mol / L HCL to adjust the pH value of the upper layer liquid phase until precipitation occurs, add the upper layer liquid phase to another centrifuge, centrifuge at 4800r / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com