Preparation method of mesoporous activated carbon for supercapacitor

A technology of mesoporous activated carbon and supercapacitor, applied in chemical instruments and methods, hybrid capacitor electrodes, inorganic chemistry, etc., can solve the problems of increasing the mesoporous ratio of activated carbon, and achieve the effect of improving rate performance, wide source and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

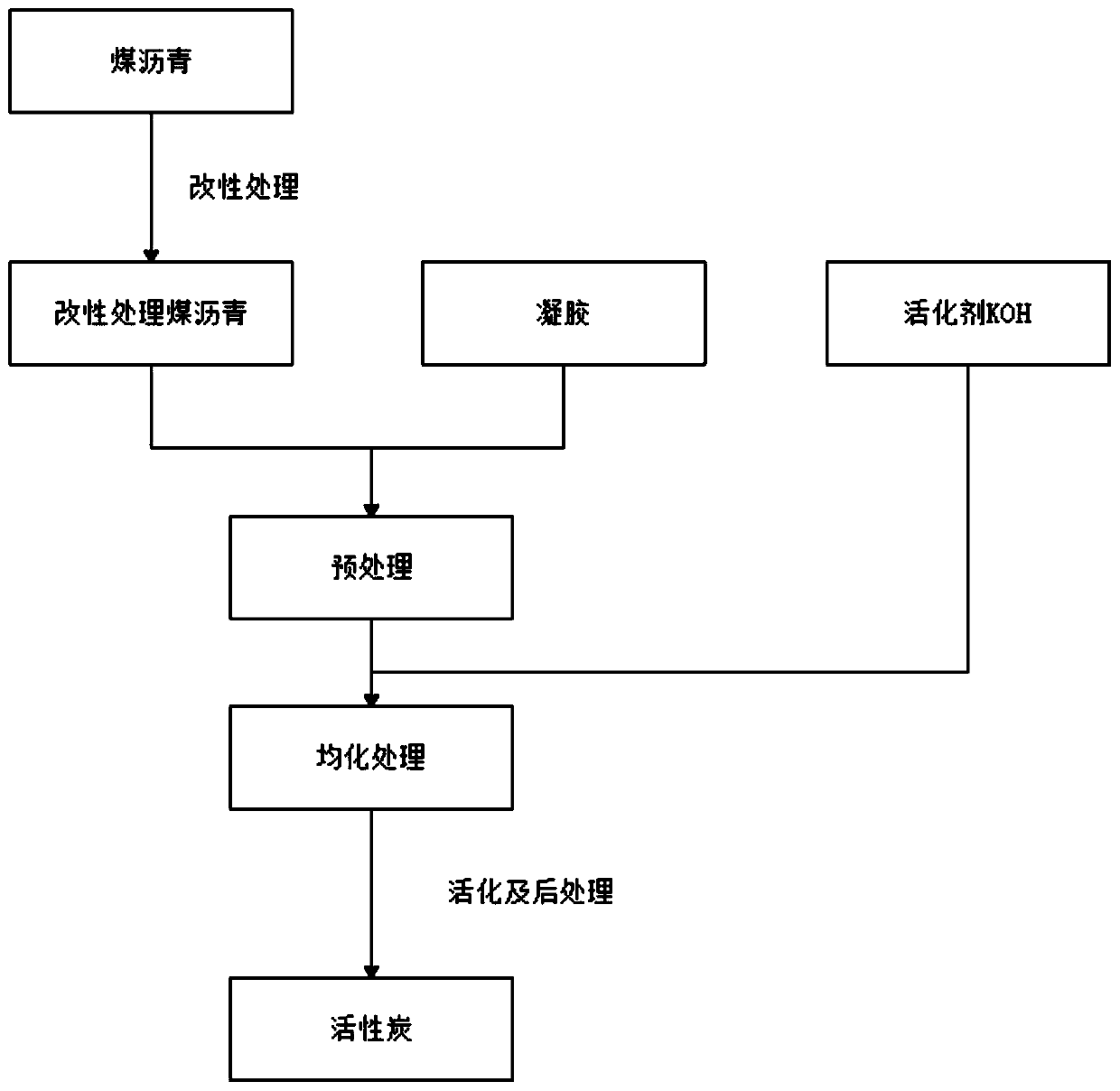

Method used

Image

Examples

Embodiment 1

[0030] The coal tar pitch is crushed to less than 0.15 mm, and the crushed coal tar pitch is oxidized and modified with 100 mL of concentrated sulfuric acid and 10 mL of hydrogen peroxide. The modification time is 24 hours, and the oxygen-containing functional group of the coal tar pitch after oxidation modification is 35.3%. The coal tar pitch treated under the above conditions was added to a carboxymethyl cellulose solution with a concentration of 2%, and pretreated at 60° C. for 2 hours to obtain a coal tar pitch composite. The coal tar pitch composite material was obtained by adding the coal tar pitch compound into the activator KOH for homogenization treatment, wherein the mass ratio of the activator KOH to the coal tar pitch compound was 2:1, the homogenization treatment temperature was 60°C, and the homogenization treatment time was 3h . After the homogenization treatment, the coal tar pitch composite material was directly activated. The activation treatment temperature...

Embodiment 2

[0032]The coal tar pitch is crushed to less than 0.15 mm, and the crushed coal tar pitch is oxidized and modified with 100 mL of concentrated sulfuric acid and 10 mL of hydrogen peroxide. The modification time is 24 hours, and the oxygen-containing functional group of the coal tar pitch after oxidation modification is 35.3%. The coal tar pitch treated under the above conditions was added to a carboxymethyl cellulose solution with a concentration of 2%, and pretreated at 70° C. for 2 hours to obtain a coal tar pitch composite. The coal tar pitch composite material was obtained by adding the coal tar pitch compound into the activator KOH for homogenization treatment, wherein the mass ratio of the activator KOH to the coal tar pitch compound was 2:1, the homogenization treatment temperature was 60°C, and the homogenization treatment time was 3h . After the homogenization treatment, the coal tar pitch composite material was directly activated. The activation treatment temperature ...

Embodiment 3

[0034] The coal tar pitch is crushed to less than 0.15 mm, and the crushed coal tar pitch is oxidized and modified with 100 mL of concentrated sulfuric acid and 8 mL of hydrogen peroxide. The modification time is 16 hours, and the oxygen-containing functional group of the coal tar pitch after oxidation modification is 28.1%. The coal tar pitch treated under the above conditions was added to a carboxymethyl cellulose solution with a concentration of 2%, and pretreated at 80° C. for 3 hours to obtain a coal tar pitch composite. The coal tar pitch composite material was obtained by adding the coal tar pitch compound into the activator KOH for homogenization treatment, wherein the mass ratio of the activator KOH to the coal tar pitch compound was 3:1, the homogenization treatment temperature was 60°C, and the homogenization treatment time was 2h . After the homogenization treatment, the coal tar pitch composite material was directly activated. The activation treatment temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com