Preparation method of carbon-doped lithium iron borate

A technology of lithium iron borate and lithium carbonate is applied in the field of preparation of carbon-doped lithium iron borate, which can solve the problems of easy absorption of moisture and oxygen, decreased product performance, large specific surface area of the product, etc. The effect of low resistance and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

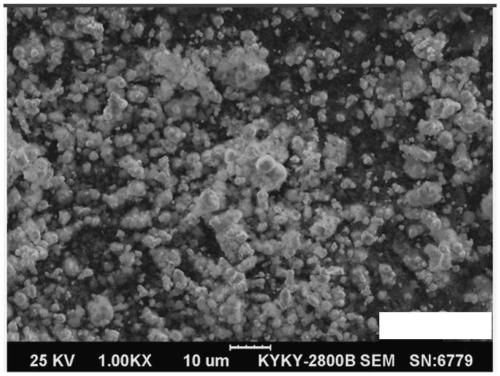

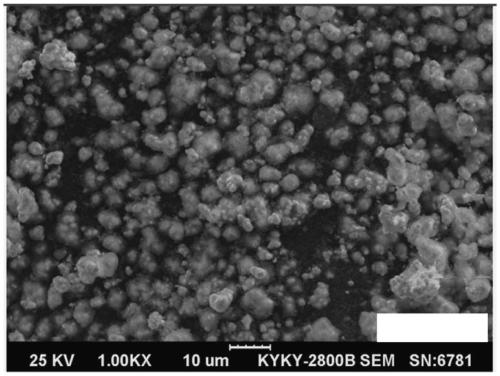

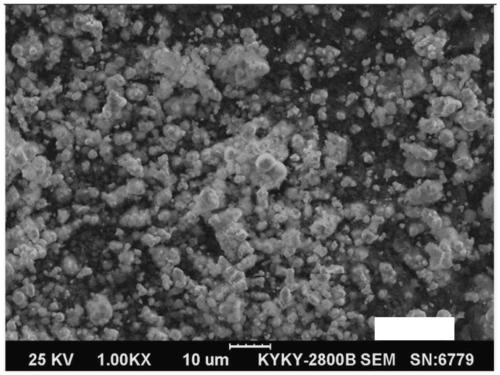

Image

Examples

Embodiment 1

[0048] A kind of preparation method of carbon-doped lithium iron borate, it is the following steps:

[0049] Add ferrocene boric acid into toluene, stir and mix evenly, then add lithium carbonate, and then pass through a sand mill until the particle size of the slurry is 147nm, and then spray dry once to obtain a spray-dried material, once spray-dried The material is put into the roller furnace for primary calcining to obtain the primary calcined material. The primary calcined material is added to xylene and paraffin, added to a ball mill and fully ground until the particle size of the primary calcined material is 1.95 μm, and then spray-dried for the second time to obtain the secondary calcined material. The spray-dried material is subjected to secondary calcining, and the secondary calcined material is air-pulverized, sieved, iron-removed and vacuum-packed to obtain carbon-doped lithium iron borate;

[0050] In a spray drying process, keep the inlet air temperature at 350°C,...

Embodiment 2

[0068] A kind of preparation method of carbon-doped lithium iron borate, it is the following steps:

[0069] Add ferrocene boric acid into toluene, stir and mix evenly, then add lithium carbonate, and then pass through a sand mill until the particle size of the slurry is 100nm, and then spray dry once to obtain a spray-dried material, once spray-dried The material is put into the roller furnace for one calcining to obtain the primary calcined material, and the primary calcined material is added to xylene and paraffin, added to a ball mill and fully ground until the particle size of the primary calcined material is 1 μm, and then the secondary spray drying is obtained to obtain the secondary spray The dried material is subjected to secondary calcining, and the secondary calcined material is air-pulverized, sieved, iron-removed and vacuum-packed to obtain carbon-doped lithium iron borate;

[0070] In a spray drying process, keep the inlet air temperature at 250°C, the temperatur...

Embodiment 3

[0086] A kind of preparation method of carbon-doped lithium iron borate, it is the following steps:

[0087] Add ferrocene boric acid into toluene, stir and mix evenly, then add lithium carbonate, and then pass through a sand mill until the particle size of the slurry is 125nm, and then spray dry once to obtain a spray-dried material, once spray-dried Put the raw material into the roller furnace for primary calcining to obtain the primary calcined material, add xylene and paraffin to the primary calcined material, add it into the ball mill and grind it fully until the particle size of the primary calcined material is 1.5 μm, and then spray dry it twice to obtain the secondary calcined material The spray-dried material is subjected to secondary calcining, and the secondary calcined material is air-pulverized, sieved, iron-removed and vacuum-packed to obtain carbon-doped lithium iron borate;

[0088] In a spray drying process, keep the inlet air temperature at 301°C, the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com