Slow rebound memory foam and preparation method thereof

A technology of memory foam and slow rebound, which is applied in the field of memory cotton, can solve the problems of not being able to significantly improve softness or air permeability, and achieve the effects of improving softness and air permeability, easy availability of raw materials, and improving softness and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

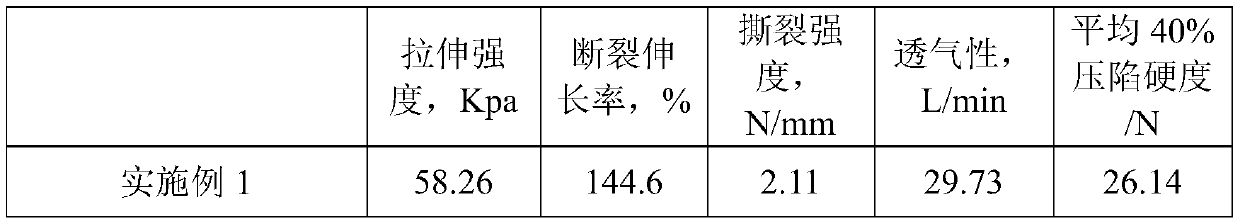

Embodiment 1

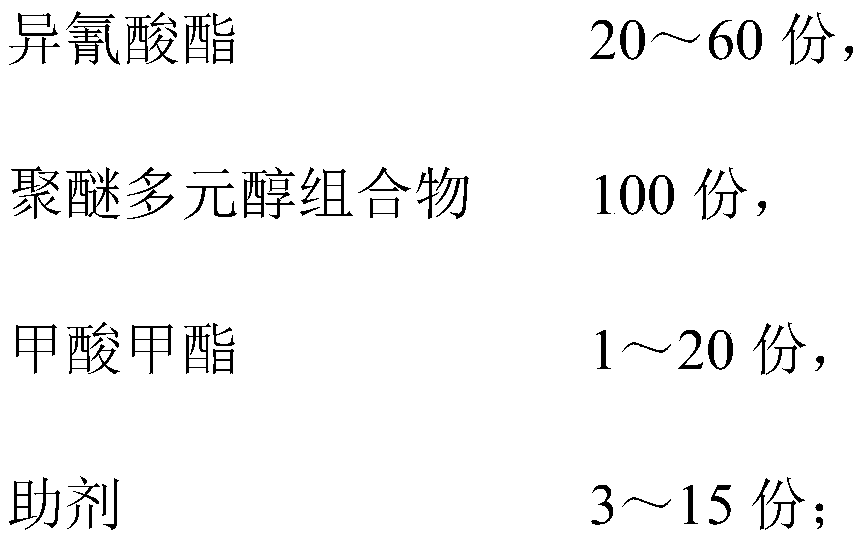

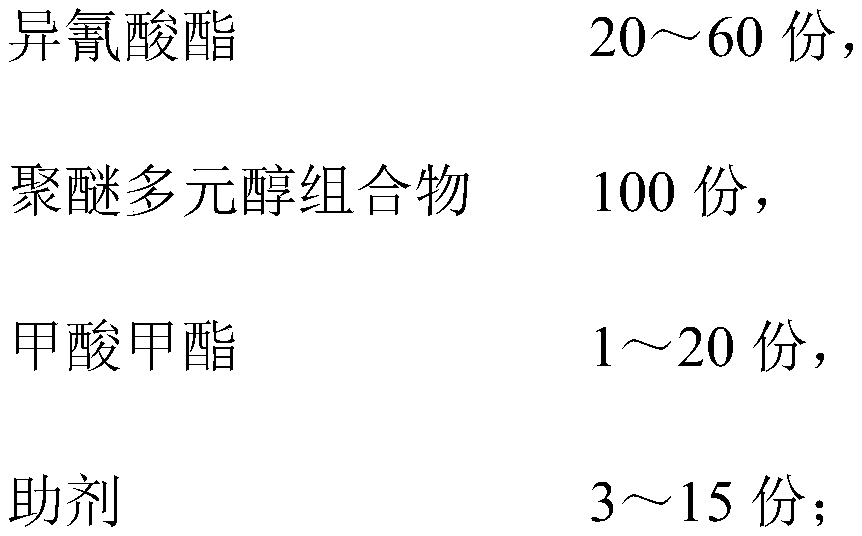

[0033] A kind of slow rebound memory cotton, its raw material composition is as follows:

[0034] Polyether polyol composition: 100 g. Among them, 70g of hydroxyl-terminated polyether, 15g of slow resilience polyether and 15g of polymer polyol are included. The hydroxyl-terminated polyether is the polyether polyol F3521 produced by Jiahua Chemical Co., Ltd., which is prepared by the copolymerization reaction of glycerol with ethylene oxide and propylene oxide as an initiator. The mass ratio is 3:2, the functionality is 3, the hydroxyl value is 40.0-44.0mg KOH / g, and the viscosity is 800-1200mPa˙s. The slow resilience polyether adopts the polyether polyol of G 308 model produced by Jiahua Chemical, which is prepared by reacting glycerin as initiator and propylene oxide, and the mass ratio of initiator and propylene oxide is 2: 3. Its functionality is 3, its hydroxyl value is 180-220 mg KOH / g, and its viscosity is 200-400 mPa˙s. The polymer polyol adopts the model of PP 3630 ...

Embodiment 2

[0046] A kind of slow rebound memory cotton, its raw material composition is as follows:

[0047] Polyether polyol composition: 100 g. Among them, 80g of hydroxyl-terminated polyether, 10g of slow resilience polyether and 10g of polymer polyol are included. The hydroxyl-terminated polyether is a P156M polyether produced by Jiahua, with a functionality of 3, a hydroxyl value of 33-37 mgKOH / g, and a viscosity of 900-1500 mPa˙s. The slow resilience polyether adopts the polyether polyol of the model G 303 produced by Jiahua, which has a functionality of 3, a hydroxyl value of 541-581 mg KOH / g, and a viscosity of 200-600 mPa˙s. The polymer polyol adopts the HP505 polymer polyol produced by Weijiahua, which has a solid content of 50, a hydroxyl value of 21-25 mgKOH / g, and a viscosity of 5000-7500 mPa˙s.

[0048] Amine catalyst: Aojia A33 0.3g.

[0049] Surfactant: Dongjun H-550 1.7g.

[0050] Foaming agent: Sinopharm methyl formate 10g.

[0051] Deionized water: 5g.

[0052] F...

Embodiment 3

[0057] A kind of slow rebound memory cotton, its raw material composition is as follows:

[0058] Polyether polyol composition: 100 g. Among them, 60g of hydroxyl-terminated polyether, 20g of slow resilience polyether and 20g of polymer polyol are included. The hydroxyl-terminated polyether is a model F 3500M polyether produced by Jiahua, with a functionality of 3, a hydroxyl value of 31-37 mgKOH / g, and a viscosity of 1050-1400 mPa˙s. The slow resilience polyether adopts the polyether polyol of the model G 305 produced by Jiahua, which has a functionality of 3, a hydroxyl value of 320-340 mg KOH / g, and a viscosity of 300-600 mPa˙s. The polymer polyol is PP3645 produced by Weijiahua, with a solid content of 42, a hydroxyl value of 18-23 mgKOH / g, and a viscosity of 5000-7500 mPa˙s.

[0059] Amine catalysts: 0.1 g of Aojia A1; 0.3 g of Aosijia A33.

[0060] Post-aging catalyst: Tosoh D 60 0.4g.

[0061] Surfactant: Dongjun H-360 1g; Dongjun H-550 0.4g.

[0062] Foaming agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap