A solid fermentation medium for promoting spore production of Metarhizium anisopliae and its preparation method and application

A solid fermentation and culture medium technology, applied in the field of microorganisms, can solve the problems of low spore germination rate, long sporulation cycle, low sporulation rate, etc., and achieve the effect of increasing sporulation, low price, and promoting sporulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

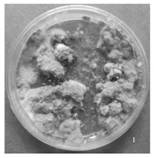

Image

Examples

preparation example Construction

[0035] The present invention further provides a method for preparing solid fermentation medium to promote spore production of Lychee aeruginosa described in the above technical scheme, comprising the following steps:

[0036] (1) The said rice is soaked in water and dried to obtain processed rice;

[0037] (2) The processed rice obtained in step (1) is mixed with soybeans, supplements, a mixture is obtained, the mixture is sterilized to give a solid fermentation medium.

[0038]The present invention is to dry the rice after soaking in water to give processed rice. In the present invention, the temperature of the water is preferably 90 ~ 100 ° C, more preferably 95 ~ 100 ° C; The soaking time is preferably 30 to 40min, more preferably 33 to 38min. In the present invention, the rice is soaked in water after drying is preferably included filtration; The method of filtration is preferably gauze filtration; The pores of the gauze are preferably 16 to 20 mesh. There are no special restr...

Embodiment 1

[0050] Preparation: 100g of rice, 100g of soybean flour and 43g of supplementary material, the particle size of the soybean flour is 50 mesh;

[0051] The supplement comprises 10g lactose, 4g glucose, yeast powder 16g, potassium nitrate 8g and peanut oil 5g.

[0052] Follow these steps to prepare solid fermentation medium:

[0053]First weigh 100g of rice in a large beaker, add 100 ° C water to soak for 30min, wash, filter with 16 mesh (gap) gauze, dry the surface moisture. Then weigh 100g of soybean flour to add, mix in 43g of supplement, mix evenly, equal amounts in a 15cm diameter, 30cm long crisp bag, 121 °C steam sterilization for 30min, cooling and standby.

[0054] Follow these steps to apply:

[0055] (1) Conidia liquid culture stage

[0056] Inoculate Lychee aerantes into solid SMAY medium (maltose 40 g / L, peptone 10 g / L, yeast extract 10 g / L, agar 18 g / L), placed in a 28 °C light incubator (16 L / 8D, alternating light and dark), and grow conidia after 7 days of incubation...

Embodiment 2

[0062] Prepare according to the mass portion: 100g of rice, 100g of soybean flour and 50g of supplementary material, the particle size of the soybean flour is 50 mesh;

[0063] The supplement comprises 10g lactose, 6g glucose, yeast powder 16g, potassium nitrate 8g and peanut oil 10g.

[0064]Follow these steps to prepare solid fermentation medium:

[0065] First weigh 100g of rice in a large beaker, add 100 ° C water to soak for 30min, wash, filter with 16 mesh (gap) gauze, dry the surface moisture. Then weigh 100g of soybean flour to add, mix in 50g of supplement, mix evenly, equal amounts in a 15cm diameter, 30cm long crisp bag, 121 °C steam sterilization for 30min, cooling and standby.

[0066] Follow these steps to apply:

[0067] (1) Conidia liquid culture stage

[0068] Inoculate Lychee aerantes into solid SMAY medium (maltose 40 g / L, peptone 10 g / L, yeast extract 10 g / L, agar 18 g / L), placed in a 28 °C light incubator (16 L / 8D, alternating light and dark), and grow conidia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com