A low-density, high-strength, high-plasticity high-entropy alloy material and preparation method thereof

A high-entropy alloy, high-strength technology, applied in the field of metal materials, can solve the problems of large difference in composition, poor compactness of sintered alloy, difficult to handle, etc., and achieve the effect of high plasticity, high strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

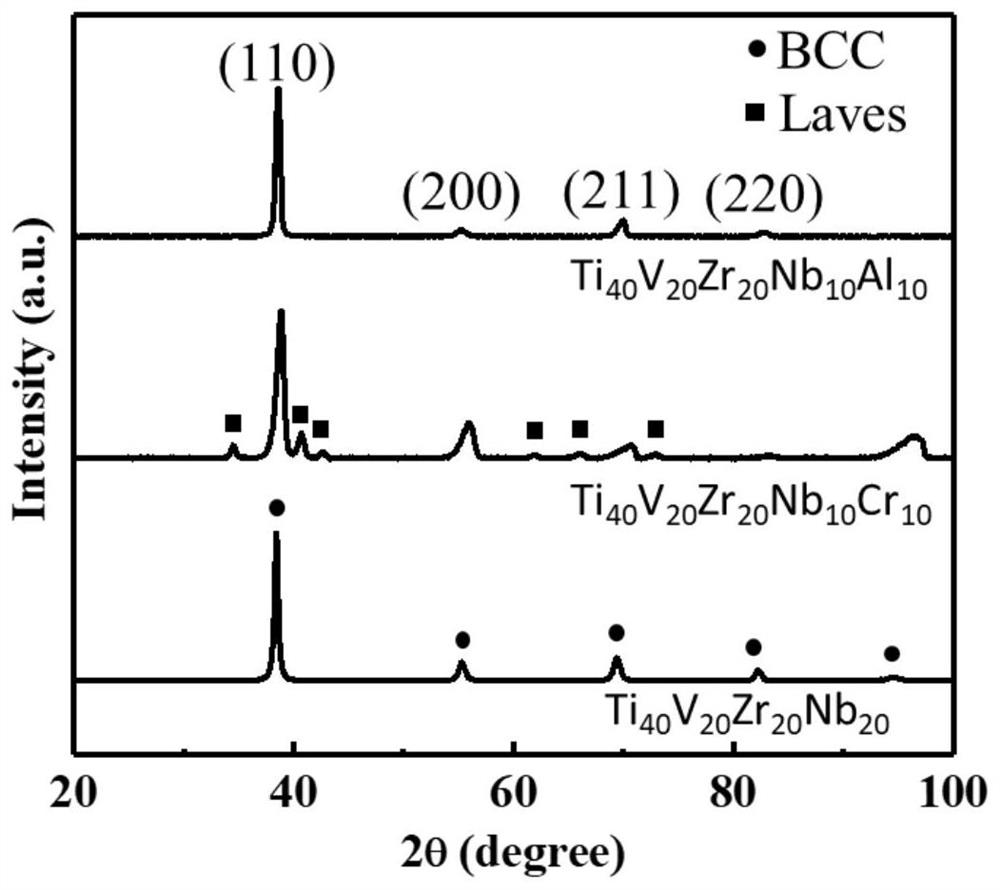

[0038] The embodiment of the present invention provides a Ti a V b Zr c Nb d x e A design and preparation method of a series of high-entropy alloy materials, including the following processes:

[0039] 1. Composition design

[0040] First, in order to obtain refractory high-entropy alloy materials with low density and high plasticity, we select low-density refractory alloy elements with intrinsic plasticity, including titanium (ρ Ti =4.54g / cm 3 ), vanadium (ρ V =6.11g / cm 3 ), zirconium (ρ Zr =6.50g / cm 3 ) and niobium (ρ Nb =8.57g / cm 3 )element. Secondly, in order to further reduce the alloy density, we choose chromium with lower density (ρ Cr =7.22g / cm 3 ) elements and ultra-light aluminum (ρ Al =2.70g / cm 3 ) element to replace the niobium element in the alloy. Finally, in order to ensure the formation of a single-phase solid solution structure after alloying and avoid the generation of intermetallic compounds that damage the properties of the alloy, we have c...

Embodiment 1

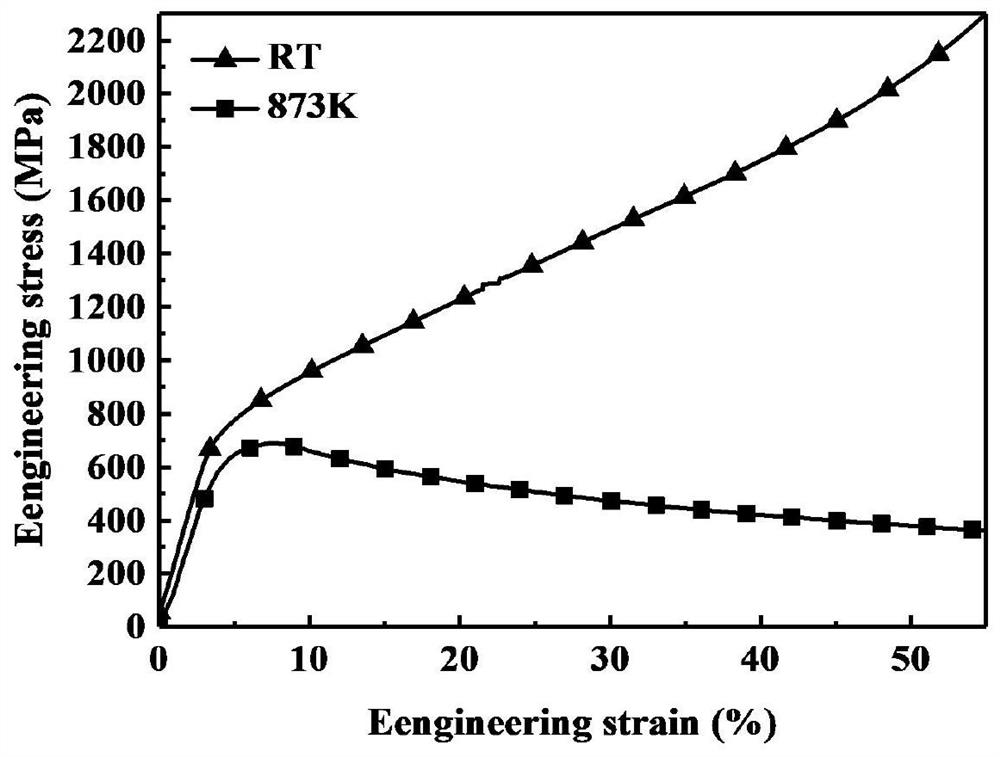

[0059] The embodiment of the present invention provides a Ti 40 V 20 Zr 20 Nb 20 High-entropy alloys are composed of four elements: Ti, V, Zr and Nb. The relative atomic percentage of Ti atoms is 40%, the relative atomic percentage of V atoms is 20%, and the relative atomic percentage of Zr atoms is 20%. The relative atomic percentage of Nb atoms is 20%.

[0060] The Ti 40 V 20 Zr 20 Nb 20 The purity of the metal element raw materials selected for the high-entropy alloy is higher than 99.95 at%.

[0061] The Ti 40 V 20 Zr 20 Nb 20 The preparation method of high entropy alloy is as follows:

[0062] Step 1: Select four metal elements Ti, V, Zr, and Nb, and clean the high-purity metal particles twice with an ultrasonic cleaner for 2 minutes each time; 40 V 20 Zr 20 Nb 20 The atomic percentage of high-entropy alloys is accurately weighed four metal elements such as Ti, V, Zr, and Nb; the copper crucible of the vacuum arc melting furnace is polished with sandpaper ...

Embodiment 2

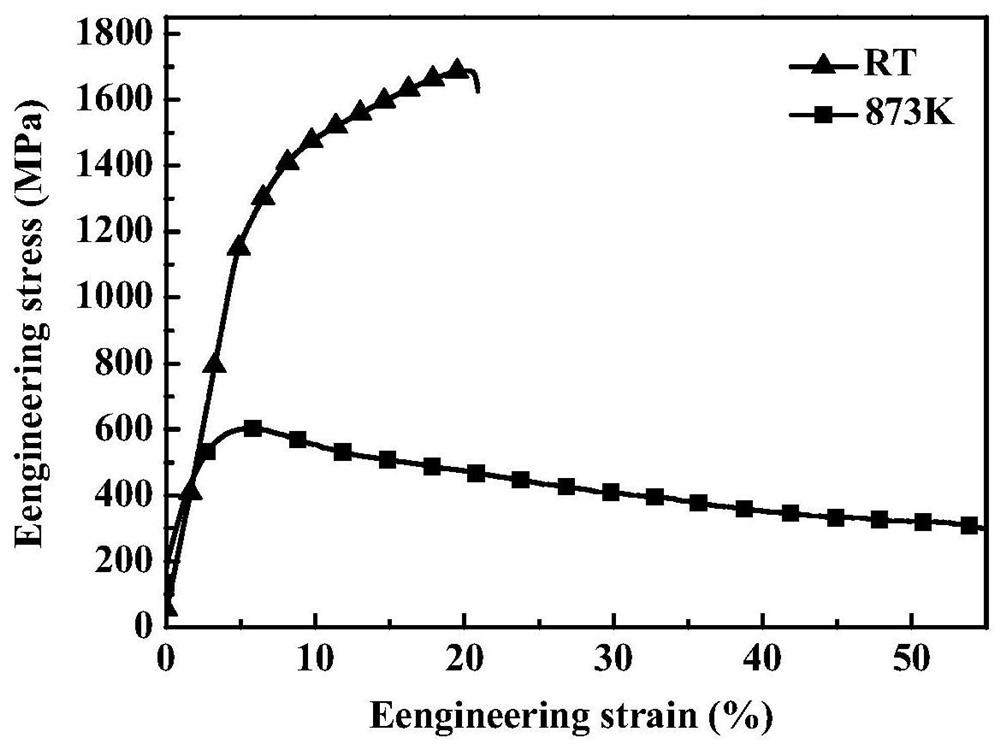

[0069] The embodiment of the present invention provides a Ti 40 V 20 Zr20 Nb 10 Cr 10 High-entropy alloys are composed of five metal elements: Ti, V, Zr, Nb and Cr. The relative atomic percentage of Ti atoms is 40%, the relative atomic percentage of V atoms is 20%, and the relative atomic percentage of Zr atoms is 20%, the relative atomic percentage of Nb atoms is 10%, and the relative atomic percentage of Cr atoms is 10%.

[0070] The Ti 40 V 20 Zr 20 Nb 10 Cr 10 The purity of the metal element raw materials selected for the high-entropy alloy is higher than 99.95 at%.

[0071] The Ti 40 V 20 Zr 20 Nb 10 Cr 10 The preparation method of high entropy alloy is as follows:

[0072] Step 1: Select five metal elements of Ti, V, Zr, Nb and Cr, and clean the high-purity metal particles twice with an ultrasonic cleaner for 2 minutes each time; 40 V 20 Zr 20 Nb 10 Cr 10 The atomic percentage of high-entropy alloys is accurately weighed five metal elements Ti, V, Zr, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com