Preparation method and product of a density-adjustable flexible polyimide foam

A polyimide and polyimide precursor technology, applied in the field of preparation of flexible polyimide foam with adjustable density, can solve the problems of increasing the complexity of the preparation process, increasing the preparation cycle, and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

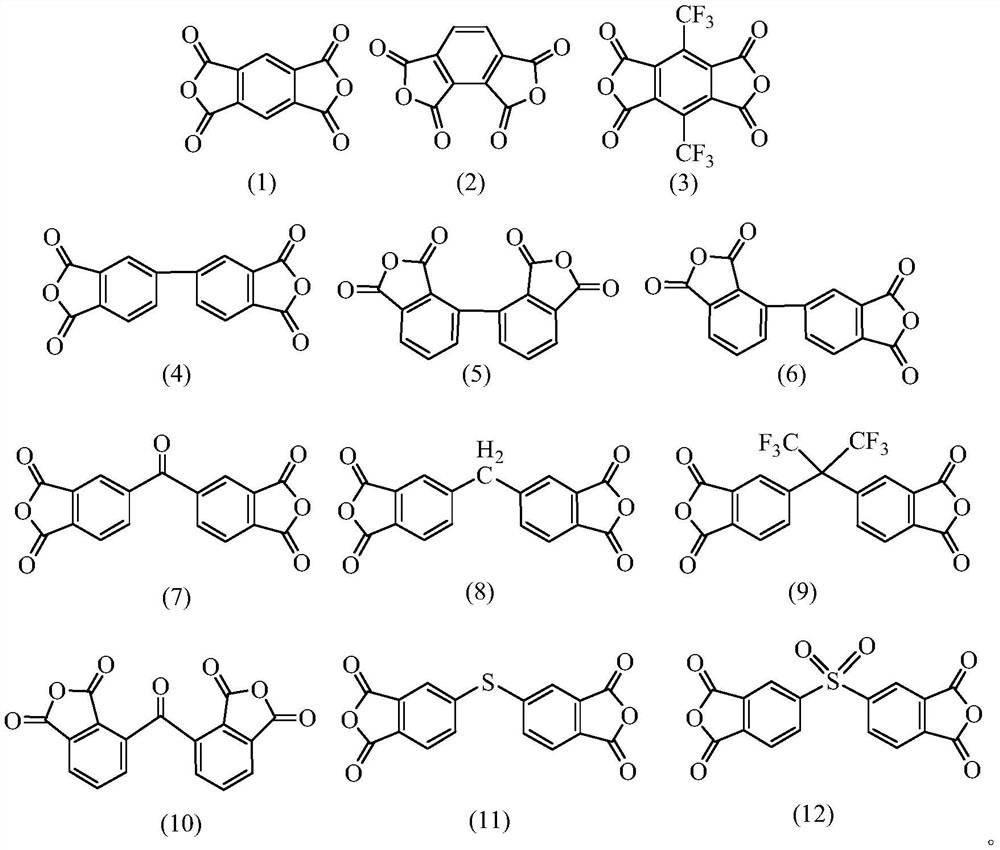

Method used

Image

Examples

Embodiment 1

[0036] Dissolve 161.12g of 3,3',4,4'-benzophenone tetraacid dianhydride in 100g of tetrahydrofuran solvent while stirring at 95°C, then add 182g of methanol for esterification reaction, and cool the solution to 5 ℃ and add 49.58g diaminodiphenylmethane, FSO surfactant 1.8g and 0.3g isoquinoline to react to prepare anhydride group-terminated polyimide precursor solution I; then adjust the reaction temperature to 25 ℃ and Slowly add 63g of polyphenyl polymethylene polyisocyanate to completely react the isocyanate group with the anhydride group and residual acid anhydride in the precursor solution, and cool to room temperature to obtain the polyimide precursor solution II.

[0037] Then use a rotary evaporator to remove most of the polar solvent in the polyimide precursor solution II by rotary evaporation at a vacuum degree of 50kPa and 45°C. The polyimide precursor evaporates during the desolvation process in the rotary evaporation bottle Steep and fill the rotary evaporator. S...

Embodiment 2

[0041] Dissolve 161.12g of 3,3',4,4'-benzophenone tetraacid dianhydride in 170g of tetrahydrofuran solvent while stirring at 100°C, then add 140g of methanol for esterification reaction, and cool the solution to 10 ℃ and add 75g diaminodiphenyl ether, FSO surfactant 2.0g and 1.0g isoquinoline to react to prepare anhydride group-terminated polyimide precursor solution I; then adjust the reaction temperature to 25 ℃ and slowly 31.5 g of diphenylmethane diisocyanate was added to completely react the isocyanate groups with the anhydride groups and residual acid anhydride in the precursor solution, and cooled to room temperature to obtain a polyimide precursor solution II.

[0042] Then use a rotary evaporator to remove most of the polar solvent in the polyimide precursor solution II by rotary evaporation at a vacuum degree of 50kPa and 45°C. The polyimide precursor evaporates during the desolvation process in the rotary evaporation bottle Steep and fill the rotary evaporator. Sub...

Embodiment 3

[0046] Dissolve 148g of 3,3',4,4'-biphenyltetraacid dianhydride in 160g of N,N-dimethylacetamide while stirring at 90°C, then add 120g of methanol for esterification reaction, and the reaction is complete After cooling the solution to 10°C and adding 52g of p-phenylenediamine, 1.0g of FSO surfactant and 0.9g of isoquinoline to react, the polyimide precursor solution I of anhydride group end-capping was obtained; the reaction temperature was adjusted to Slowly add 6.5g of diphenylmethane diisocyanate at 20°C to completely react the isocyanate group with the anhydride group and residual anhydride in the precursor solution, and cool to room temperature to obtain the polyimide precursor solution II.

[0047] Then use a rotary evaporator to remove most of the polar solvent in the polyimide precursor solution II by rotary evaporation at a vacuum degree of 40kPa and 45°C. The polyimide precursor evaporates during the desolvation process in the rotary evaporation bottle Steep and fill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com