Energy-saving and emission-reducing gas-fired boiler pre-heating method and facility

A gas-fired boiler, energy-saving and emission-reduction technology, applied in separation methods, boiler cleaning devices, chemical instruments and methods, etc., can solve the problems of heat loss, environmental pollution, non-energy saving, etc., to reduce pollutant discharge, save fossil energy, protect The effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

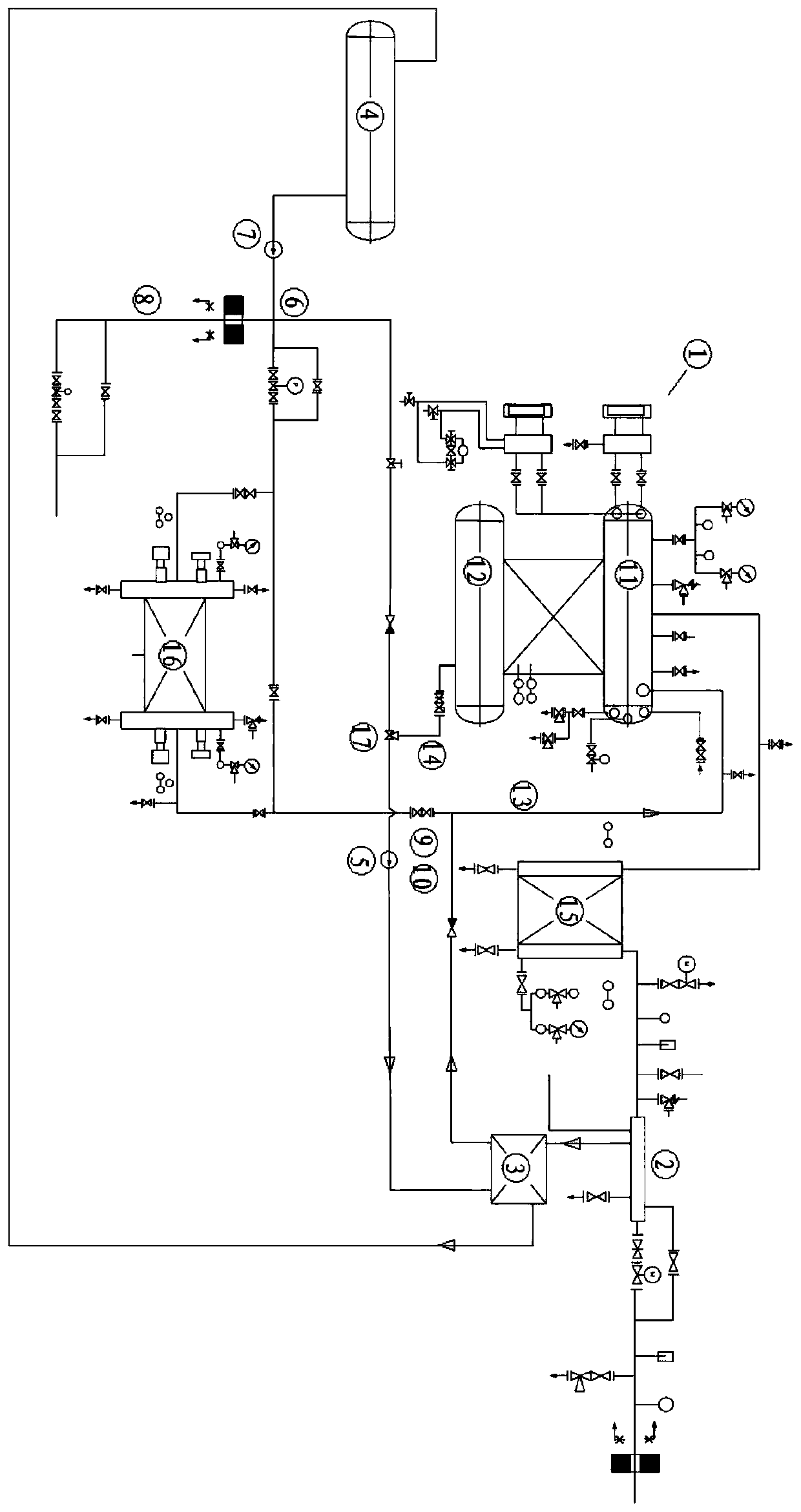

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0024] In order to ensure the reliability of boiler steam supply or heat supply, the steam supply system of the energy station will definitely flow the steam of at least two boilers into the steam outlet pipe. At present, the common practice is to bring the steam of at least two boilers into the sub-cylinders, and the sub-cylinders distribute the generated steam to various pipelines.

[0025] The energy-saving and emission-reducing gas-fired boiler preheating method disclosed in the present invention leads a steam heat source from the steam outlet main pipe of the steam supply system to the heat exchanger, and the cold end water source is heated by the heat exchanger to the upper pot of the preheating boiler The tube is supplied with water, and the fixed-row pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com