Airtight container leakage positioning and measuring system based on ultrasonic detection

A technology of positioning measurement and ultrasonic detection, which is applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree for liquid tightness measurement, etc., which can solve the problem of low accuracy of detection method, unsafe and simple operation, and method limitations Large and other problems, to achieve the effect of huge market promotion and application potential, safe and simple operation, and small method limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The technical solution of the ultrasonic detection-based airtight container leak location measurement system provided by the present invention will be further described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention and implement it.

[0065] 1. The overall design plan

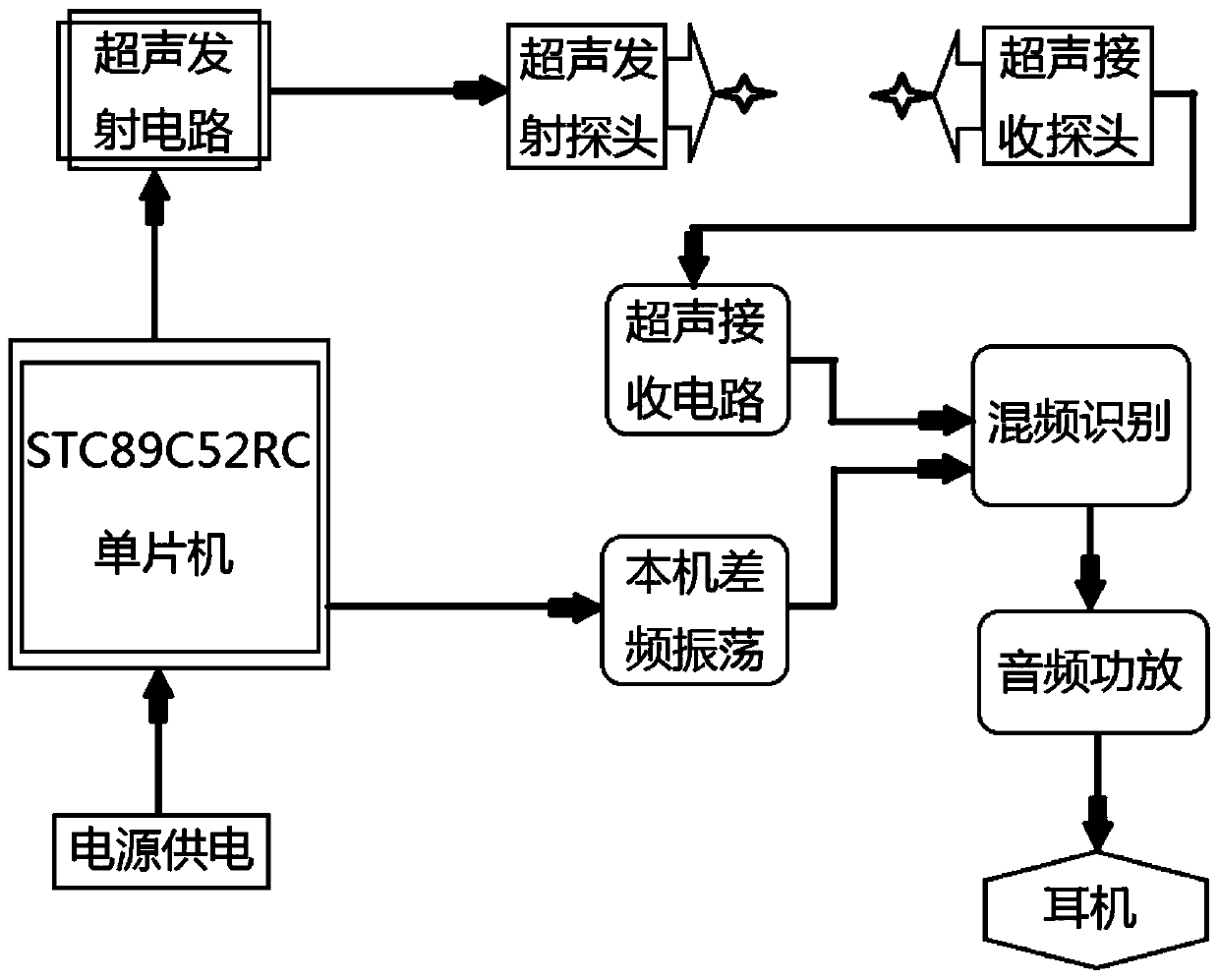

[0066] The airtight container leakage location measurement system based on ultrasonic detection of the present invention realizes two basic functions: one is to down-convert the generated high-frequency ultrasonic signal into an audio signal and make a sound through the earphone; the other is to realize the plane positioning of the sound source, and the system function Design schematic as figure 1 shown.

[0067] Such as figure 1 As shown, the airtight container leak location measurement system based on ultrasonic detection of the present invention includes a main control single-chip microcomputer, an ultrasonic transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com