Rotary motion type automatic electrolytic polishing device and method for EBSD test sample

A technology of electropolishing and rotating motion, which is applied in the direction of measuring devices, preparation of test samples, electrolysis process, etc. It can solve problems such as difficulty in maintaining voltage and current stability, difficulty in high-quality surfaces, failure of electropolishing, etc., to prevent surface The effects of burning, promoting timely shedding, and improving the quality of electrolytic polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

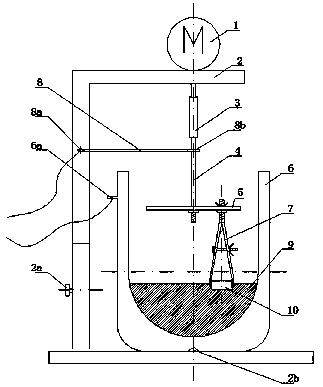

[0022] In this embodiment, a kind of automatic electrolytic polishing device for rotary motion type EBSD test sample is as follows: figure 1 shown.

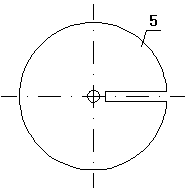

[0023] A rotary motion type EBSD test sample electrolytic polishing device is characterized in that the device includes a liftable cantilever with a positioning cone support 2, a hemispherical inner bottom surface electrolytic polishing tank 6, a herringbone clamp 7, a position adjustment chuck 5 and The motor 1 is characterized in that the liftable cantilever with a positioning cone support 2 is a "匚" type structure, the motor 1 is placed above the cantilever, and the position is adjusted through the insulating connecting rod 3 and the metal connecting rod 4 sequentially from top to bottom. The centers of the chucks 5 are connected, and a herringbone clamp 7 is placed under the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com