Cobalt nickel selenide nitrogen-doped amorphous carbon nano composite negative electrode material as well as preparation and application thereof

A technology of cobalt-nickel-nitrogen selenide and amorphous carbon, which is applied in the field of materials, can solve the problems of many impurities and reduce the sodium storage performance of materials, and achieve the effects of enhancing sodium storage performance, facilitating transmission, and increasing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

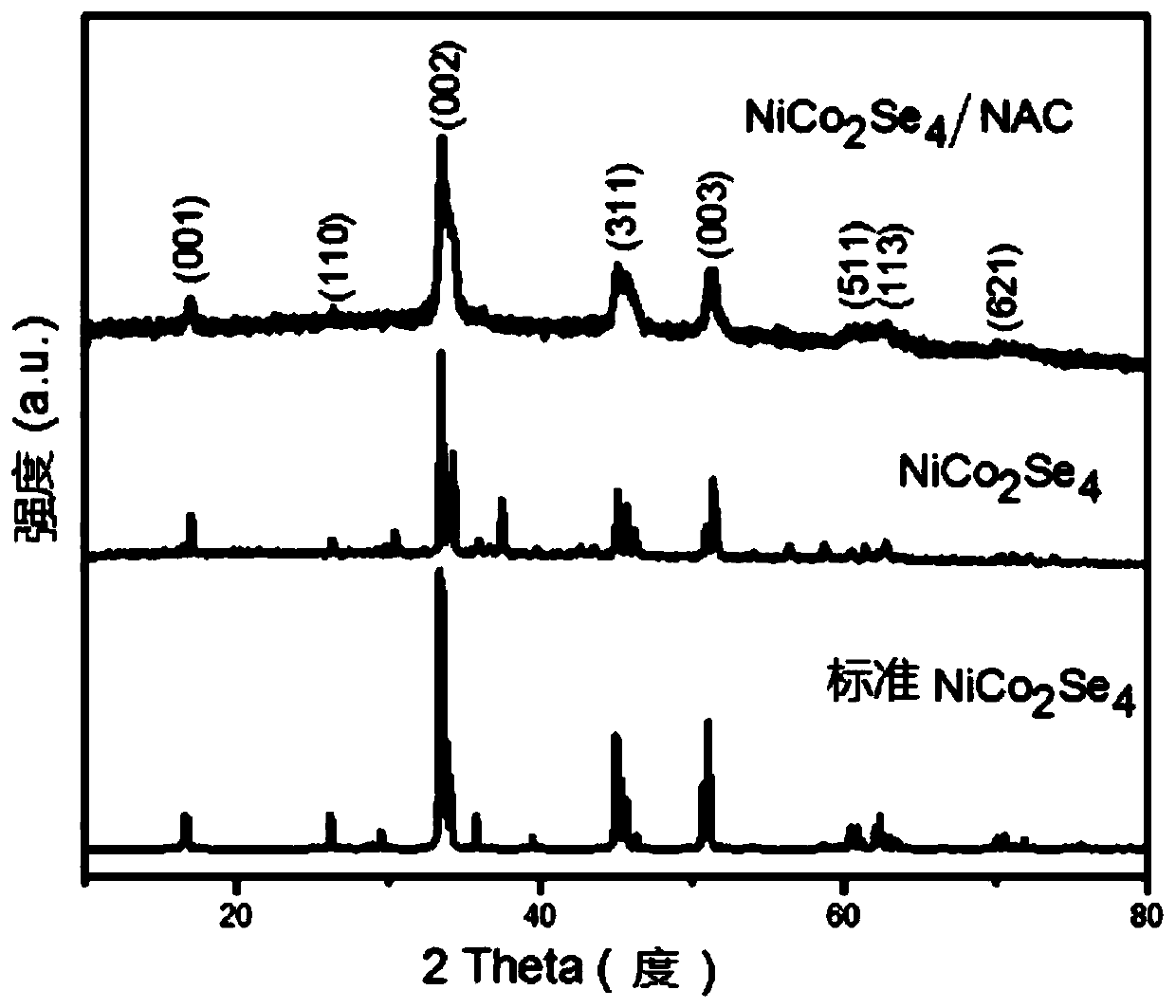

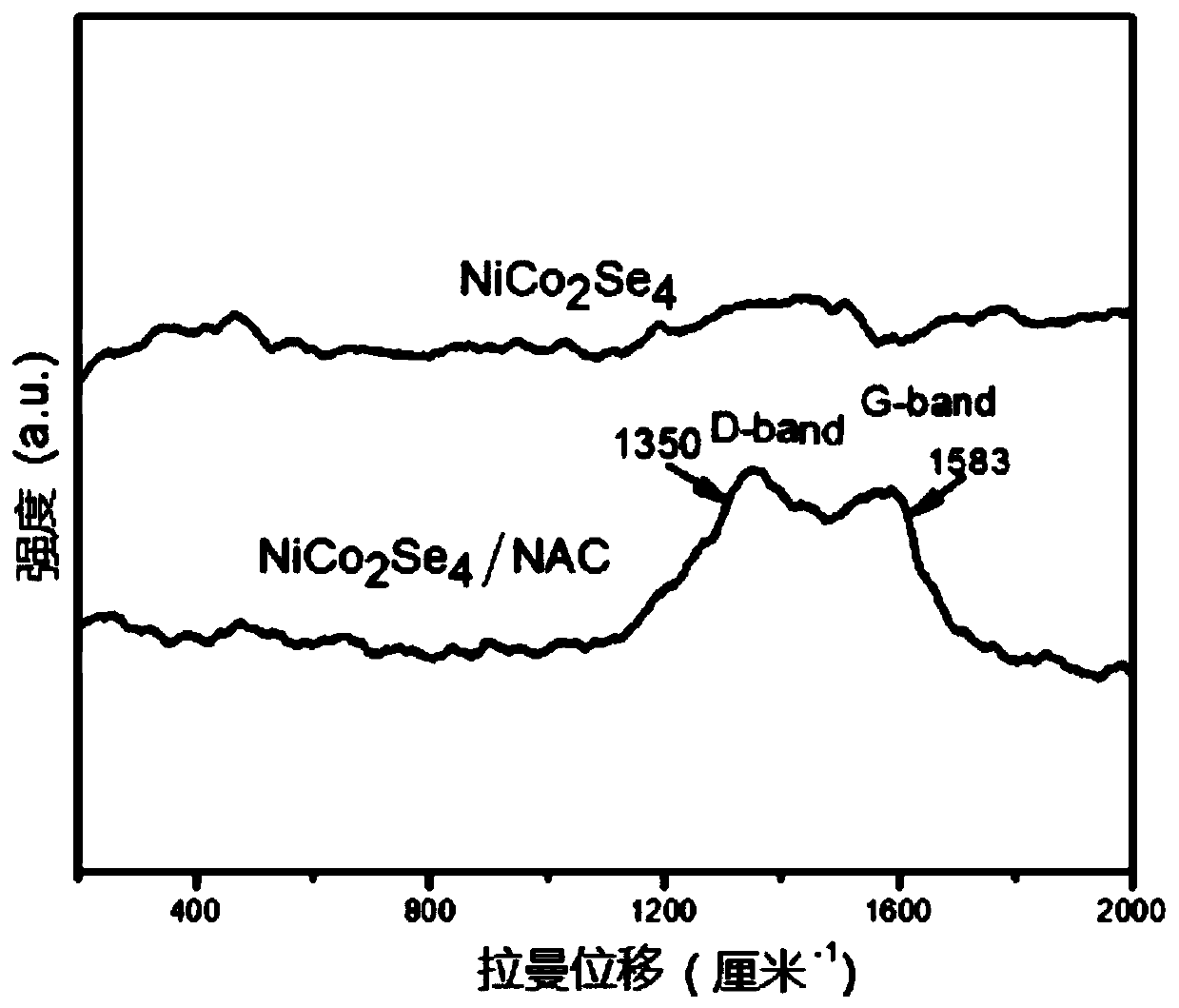

[0038] A cobalt-nickel-nitrogen-doped amorphous carbon nanocomposite negative electrode material, in which carbon is used as a skeleton, amorphous and doped with nitrogen, the particle size of the composite material is 80-150nm, and the entire material forms a porous structure. Prepared by the following steps:

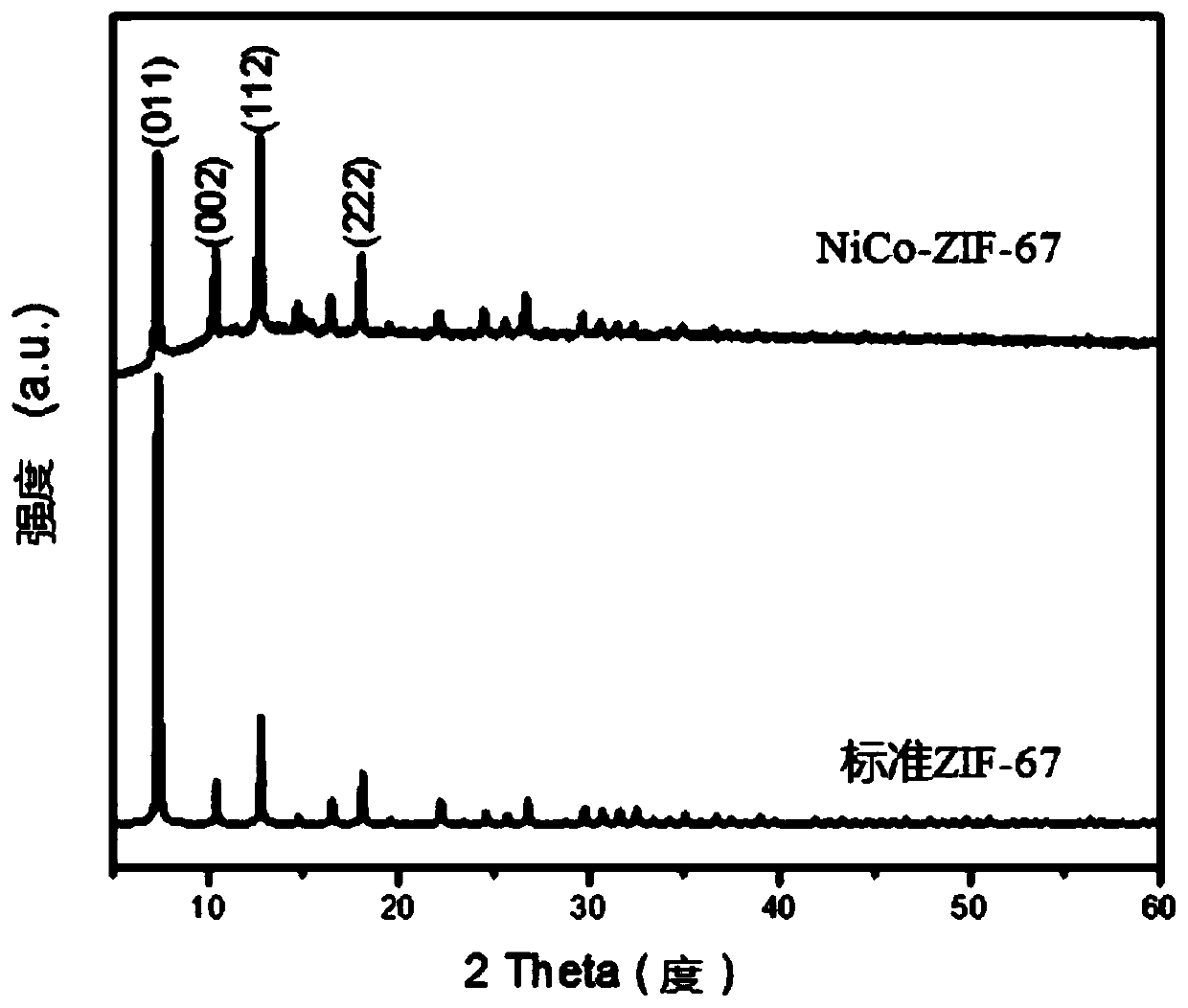

[0039] Step 1. Ni / Co-ZIF-67 nanocubes were prepared using a simple liquid phase method. First, 2mmol (0.5821g) of Co(NO 3 ) 2 ·6H 2 O, 1mmol (0.2908g) of Ni(NO 3 ) 2 ·6H 2 O and 20mg cetyltrimethylammonium bromide (CTAB) are added in 25mL water to form an aqueous solution;

[0040] Step 2. Quickly pour the above solution into 175mL 2-methylimidazole aqueous solution (11.3g), then stir it at room temperature at a speed of 3000-5000r / min for 60min, and then let it stand at room temperature for 24h to obtain a suspension liquid;

[0041] Step 3: Vacuum filter the above suspension for 10-20 minutes to obtain a precipitate, which is washed three times with deionized...

Embodiment 2

[0049] A cobalt-nickel-nitrogen-doped amorphous carbon nanocomposite negative electrode material, in which carbon is used as a skeleton, amorphous and doped with nitrogen, the particle size of the composite material is 80-150nm, and the entire material forms a porous structure. Prepared by the following steps:

[0050] Step 1. NiCo-ZIF-67 nanocubes were prepared using a simple liquid-phase method. First, 2mmol (0.5821g) of Co(NO 3 ) 2 ·6H 2 O, 1mmol (0.2908g) of Ni(NO 3 ) 2 ·6H 2 O and 20mg cetyltrimethylammonium bromide (CTAB) are added in 25mL water to form an aqueous solution;

[0051] Step 2. Quickly pour the above solution into 175mL 2-methylimidazole aqueous solution (11.3g), then stir it at room temperature at a speed of 3000-5000r / min for 40min, and then let it stand at room temperature for 24h to obtain a suspension liquid;

[0052] Step 3: Vacuum filter the above suspension for 10-20 minutes to obtain a precipitate, wash the precipitate with deionized water a...

Embodiment 3

[0057] A cobalt-nickel-nitrogen-doped amorphous carbon nanocomposite negative electrode material, in which carbon is used as a skeleton, amorphous and doped with nitrogen, the particle size of the composite material is 80-150nm, and the entire material forms a porous structure. Prepared by the following steps:

[0058] Step 1. NiCo-ZIF-67 nanocubes were prepared using a simple liquid-phase method. First, 2mmol (0.5821g) of Co(NO 3 ) 2 ·6H 2 O, 1mmol (0.2908g) of Ni(NO 3 ) 2 ·6H 2 O and 20mg cetyltrimethylammonium bromide (CTAB) are added in 25mL water to form an aqueous solution;

[0059] Step 2. Quickly pour the above solution into 175mL 2-methylimidazole aqueous solution (11.3g), then stir it at room temperature at a speed of 3000-5000r / min for 40min, and then let it stand at room temperature for 12h to obtain a suspension liquid;

[0060] Step 3: Vacuum filter the above suspension for 10-20 minutes to obtain a precipitate, which is washed with deionized water and ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com