Lanthanum-doped titanium trioxide coated co-modified lithium zinc titanate composite material and preparation method thereof

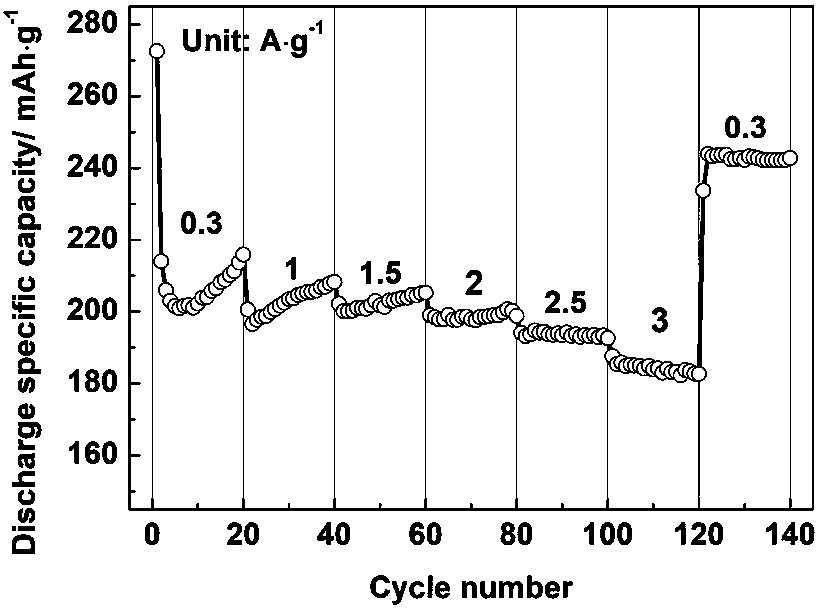

A technology of titanium dioxide and composite materials, applied in chemical instruments and methods, titanium oxide/hydroxide, titanate, etc., can solve the problems of complicated steps, pressure resistance requirements of high-pressure reactors, harsh preparation conditions, etc. To achieve the effect of improving ionic conductivity and improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

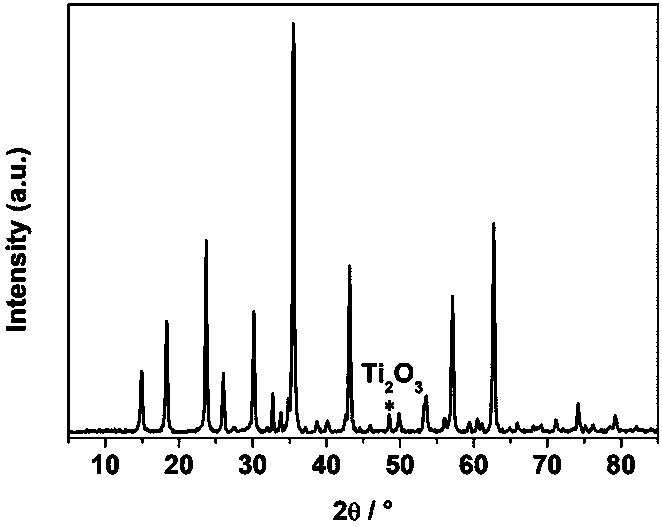

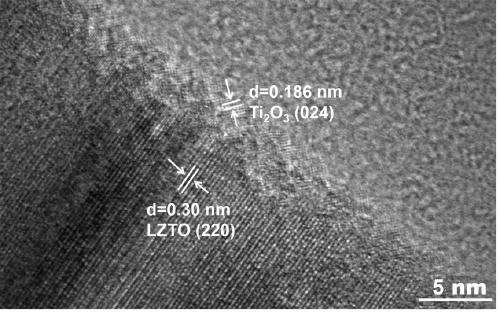

[0052]A lithium-zinc titanate composite material coated with co-modified lanthanum-doped titanium oxide, the molecular formula of the composite material is Li 1.95 La 0.05 ZnTi 3 o 8 @Ti 2 o 3 , from lithium salt, lanthanum source, zinc source and titanium source according to the amount of substance n Li :n La :n Zn :n Ti =2.15:0.05:1:3 mixed and sintered, the lithium salt is Li 2 CO 3 , the lanthanum source is La(NO 3 ) 3 ·6H 2 O, zinc source is ZnO, titanium source is rutile TiO 2 .

[0053] The preparation method of above-mentioned composite material, comprises the steps:

[0054] Step A: Li 2 CO 3 , La(NO 3 ) 3 ·6H 2 O, ZnO and rutile TiO 2 Precursors were obtained by ball milling in absolute ethanol for 5 h, where n Li :n La :n Zn :n Ti =2.15︰0.05:1︰3; the ratio of absolute ethanol to lithium salt is: 3mL:0.2 g;

[0055] Step B: Dry the precursor obtained in step A in an oven for 1 h at a drying temperature of 80 °C;

[0056] Step C: Grinding the...

Embodiment 2

[0065] A lithium-zinc titanate composite material coated and co-modified with lanthanum-doped titanium oxide, the molecular formula of the negative electrode material is Li 1.97 La 0.03 ZnTi 3 o 8 @Ti 2 o 3 , from lithium salt, lanthanum source, zinc source and titanium source according to the amount of substance n Li :n La :n Zn :n Ti =2.17:0.03:1:3 mixed and sintered, the lithium salt is Li 2 CO 3 , the lanthanum source is La(NO 3 ) 3 ·6H 2 O, zinc source is ZnO, titanium source is rutile TiO 2 .

[0066] The preparation method of above-mentioned composite material, comprises the steps:

[0067] Step A: Li 2 CO 3 , La(NO 3 ) 3 ·6H 2 O, ZnO and rutile TiO 2 Precursors were obtained by ball milling in absolute ethanol for 6 h, where n Li :n La :n Zn :n Ti =2.17︰0.03:1︰3; the ratio of absolute ethanol to lithium salt is: 3mL:0.2g;

[0068] Step B: drying the precursor obtained in Step A in an oven for 2 h, and the temperature of the oven is 60°C;

[00...

Embodiment 3

[0076] A lithium-zinc titanate composite material coated and co-modified with lanthanum-doped titanium oxide, the molecular formula of the negative electrode material is Li 1.96 La 0.04 ZnTi 3 o 8 @Ti 2 o 3 , from lithium salt, lanthanum source, zinc source and titanium source according to the amount of substance n Li :n La :n Zn :n Ti =2.06:0.04:1:3 mixed and sintered, the lithium salt is CH 3 COOLi·2H 2O, the lanthanum source is La(NO 3 ) 3 ·6H 2 O, the zinc source is Zn(CH 3 COO) 2 2H 2 O, titanium source is anatase TiO 2 .

[0077] The preparation method of above-mentioned composite material, comprises the steps:

[0078] Step A: Change the CH 3 COOLi·2H 2 O, La(NO 3 ) 3 ·6H 2 O, Zn(CH 3 COO) 2 2H 2 O and anatase TiO 2 Precursors were obtained by ball milling in absolute ethanol for 4 h, where n Li :n La :n Zn :n Ti =2.06:0.04:1:3; the ratio of absolute ethanol to lithium salt is: 1.5 mL: 0.6 g;

[0079] Step B: drying the precursor obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com