System and method for increasing yield of p-xylene by utilizing carbon-rich natural gas

A paraxylene and natural gas technology, applied in the system field of increasing production of paraxylene, can solve the problems of natural gas loss, greenhouse gas emissions, energy consumption increase, etc., and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

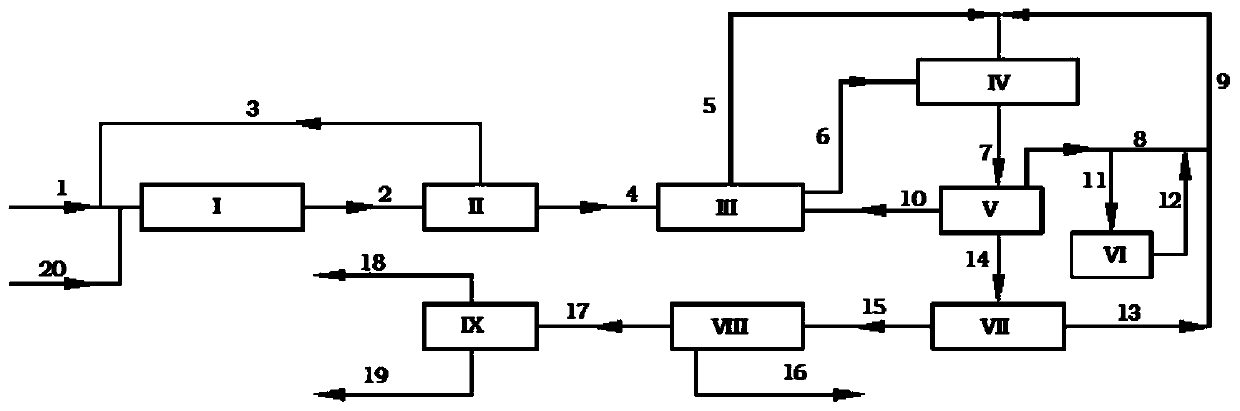

[0063] This embodiment provides a system for increasing the production of p-xylene by utilizing carbon-rich natural gas, the system structure is as follows figure 1 As shown, the system includes sequentially connected methanol synthesis integrated unit I, methanol product separation unit II, methanol stripping unit III, toluene methanol alkylation reaction unit IV, three-phase separation unit V, toluene circulation unit VII and two Toluene separation and purification unit;

[0064] The inlet of the methanol synthesis integration unit I is connected with a feed pipeline, and the feed pipeline is divided into two branches, one is a carbon-rich natural gas pipeline, and the other is a feed carbon-hydrogen ratio reconciliation pipeline;

[0065] The methanol synthesis integrated unit I includes a sequentially connected reforming unit and a methanol preparation unit;

[0066] The methanol product separation unit II is provided with a crude methanol outlet and an unreacted hydrocar...

Embodiment 2

[0073] This embodiment provides a method for increasing the production of p-xylene by using carbon-rich natural gas. The method is to use the system for increasing the production of p-xylene by utilizing carbon-rich natural gas provided in Implementation 1. The method includes the following steps:

[0074] CO in the carbon-rich natural gas raw material in this example 2 The content is 20%, through the purification device, dehydration, heavy hydrocarbon separation, desulfurization and mercury removal and other purification treatments are carried out.

[0075] (1) Use 600kmol steam to purify the described carbon-rich natural gas raw material (composition CO 2 Content 20%, 80% CH 4 ) after the carbon-hydrogen ratio is reconciled, enter the methanol synthesis integrated unit I to carry out reforming reaction and methanol preparation reaction in sequence, the pressure of the reforming reaction is 5Mpag, the temperature is 1200 ° C, the product after the reforming reaction The mol...

Embodiment 3

[0080] This embodiment provides a method for increasing the production of p-xylene by using carbon-rich natural gas. The method is to use the system for increasing the production of p-xylene by utilizing carbon-rich natural gas provided in Implementation 1. The method includes the following steps:

[0081] CO in the carbon-rich natural gas raw material in this example 2 The content is 12.5%. After the purification device, dehydration, separation of heavy hydrocarbons, desulfurization and mercury removal are carried out.

[0082] (1) Use 375kmol water vapor to purify the described carbon-rich natural gas raw material of 1000kmol / h (composition CO 2 Content 12.5%, 87.5% CH 4 ) after the carbon-hydrogen ratio is reconciled, enter the methanol synthesis integrated unit I to carry out reforming reaction and methanol preparation reaction in sequence, the pressure of the reforming reaction is 3Mpag, the temperature is 900 ° C, the product after the reforming reaction The molar rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com