High-hardness and high-fullness special coating for wheels, and preparation method thereof

A fullness and high hardness technology, which is applied in the field of high hardness and high fullness wheel special coating and its preparation, can solve the problems of poor water resistance, poor workability, poor fullness, etc., and achieve reduced production costs, high fullness, and high density. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

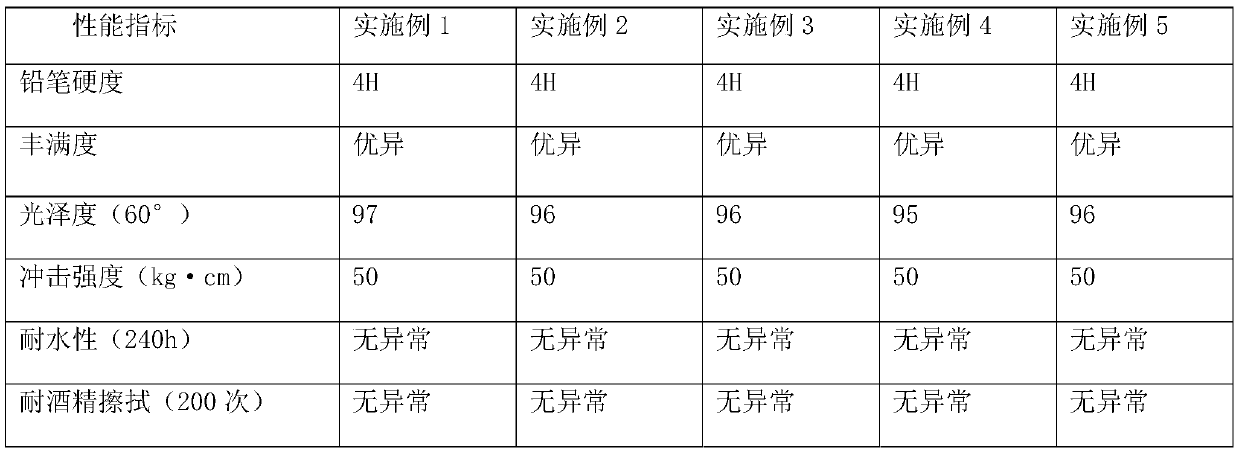

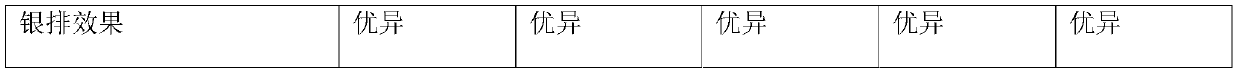

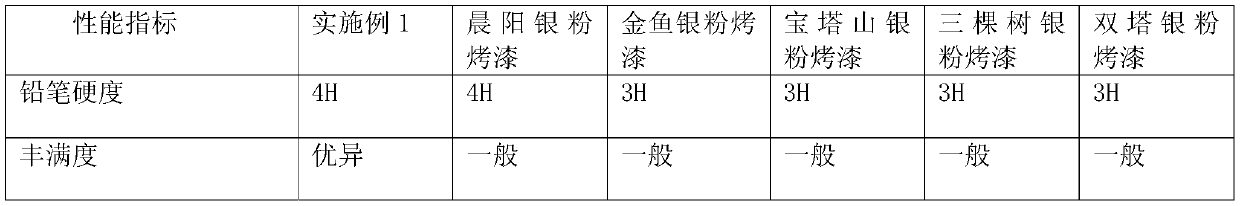

Examples

Embodiment 1

[0036] A special coating for wheels with high hardness and high fullness

[0037] The coating, in parts by weight, comprises 32 parts of water-based resin, 0.2 part of water-based defoamer, 0.2 part of water-based leveling agent, 0.6 part of substrate wetting agent, 1 part of water-based modified polyurethane dispersant, 1.6 parts of neutralizer, 4.5 parts of water-based aluminum silver powder, 6.5 parts of water-based amino resin, 45 parts of deionized water, 1 part of wax emulsion, and 8 parts of co-solvent.

[0038] Further, the water-based resin is a water-based polyester resin;

[0039] Further, the defoamer is an aqueous silicone defoamer;

[0040] Further, the leveling agent is a silicone leveling agent;

[0041] Further, the water-based modified polyurethane dispersant is modified polyurethane;

[0042] Further, the neutralizing agent is alcohol amines;

[0043] Further, the wax emulsion is a modified ethylene vinyl acetate copolymer wax emulsion;

[0044] Further...

Embodiment 2

[0050] A special coating for wheels with high hardness and high fullness

[0051] The coating, in parts by weight, comprises 30 parts of water-based resin, 0.2 part of water-based defoamer, 0.2 part of water-based leveling agent, 0.6 part of substrate wetting agent, 1 part of water-based modified polyurethane dispersant, 1.5 parts of neutralizer, 4.5 parts of water-based aluminum silver powder, 6 parts of water-based amino resin, 50.1 parts of deionized water, 0.5 parts of wax emulsion, and 6 parts of co-solvent.

[0052] Further, the water-based resin is a water-based polyester resin;

[0053] Further, the defoamer is an aqueous silicone defoamer;

[0054] Further, the leveling agent is a silicone leveling agent;

[0055] Further, the water-based modified polyurethane dispersant is modified polyurethane;

[0056] Further, the neutralizing agent is alcohol amines;

[0057] Further, the wax emulsion is a modified ethylene vinyl acetate copolymer wax emulsion;

[0058] Furt...

Embodiment 3

[0064] A special coating for wheels with high hardness and high fullness

[0065] The coating, in parts by weight, comprises 32 parts of water-based resin, 0.2 part of water-based defoamer, 0.2 part of water-based leveling agent, 0.6 part of substrate wetting agent, 1 part of water-based modified polyurethane dispersant, 1.7 parts of neutralizer, 4.8 parts of water-based aluminum silver powder, 6.5 parts of water-based amino resin, 45.9 parts of deionized water, 0.7 parts of wax emulsion, and 7 parts of co-solvent.

[0066] Further, the water-based resin is a water-based polyester resin;

[0067] Further, the defoamer is an aqueous silicone defoamer;

[0068] Further, the leveling agent is a silicone leveling agent

[0069] Further, the water-based modified polyurethane dispersant is modified polyurethane;

[0070] Further, the neutralizing agent is alcohol amines;

[0071] Further, the wax emulsion is a modified ethylene vinyl acetate copolymer wax emulsion;

[0072] Fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com