Organic selenium-rich rice cultivation and selenium-rich rice byproduct comprehensive utilization method

A technology for rice cultivation and by-products, applied in rice cultivation, organic fertilizer, fruit tree cultivation and other directions, can solve the problems of high content of selenium fertilizer, low safety, pollution, etc., and achieve high organic selenium content, reduce production costs, and reduce application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] see Figure 1-11 As shown, the present embodiment is a method for the cultivation of organic selenium-enriched rice and comprehensive utilization of by-products of selenium-enriched rice. The method for cultivating organic selenium-enriched rice comprises the following steps:

[0051] Step 1: When rice seedlings are raised, selenium-rich seedling substrates are used, sowing seeds are sown at a rate of 0.8 per square meter, and the thickness of the cover is 0.5;

[0052] Step 2: Before rice transplantation, apply organic selenium-enriched special fertilizer as base fertilizer, and the application rate is 20 per mu; after plowing the land, evenly spread organic selenium-enriched special fertilizer as surface fertilizer, and the application rate is 10 per mu;

[0053] Step 3: Apply organic selenium-enriched special fertilizer as topdressing fertilizer at the end of rice tillering stage before putting it on the field, and the application rate is 30 per mu;

[0054] Step 4:...

Embodiment 2

[0071] see Figure 1-11 As shown, the present embodiment is a method for the cultivation of organic selenium-enriched rice and comprehensive utilization of by-products of selenium-enriched rice. The method for cultivating organic selenium-enriched rice comprises the following steps:

[0072] Step 1: When rice seedlings are raised, selenium-rich seedling substrates are used to sow 0.9 kg of bud seeds per square meter, and the thickness of the cover is 1 cm;

[0073] Step 2: Before rice transplantation, apply organic selenium-enriched special fertilizer as base fertilizer, and the application rate is 35 kg per mu; after plowing the land, evenly spread organic selenium-enriched special fertilizer as surface fertilizer, and the application rate is 25 kg per mu;

[0074] Step 3: Apply organic selenium-enriched special fertilizer as topdressing before the paddy rice is put on the field at the end of tillering stage, and the application rate is 60 kg per mu;

[0075] Step 4: When th...

Embodiment 3

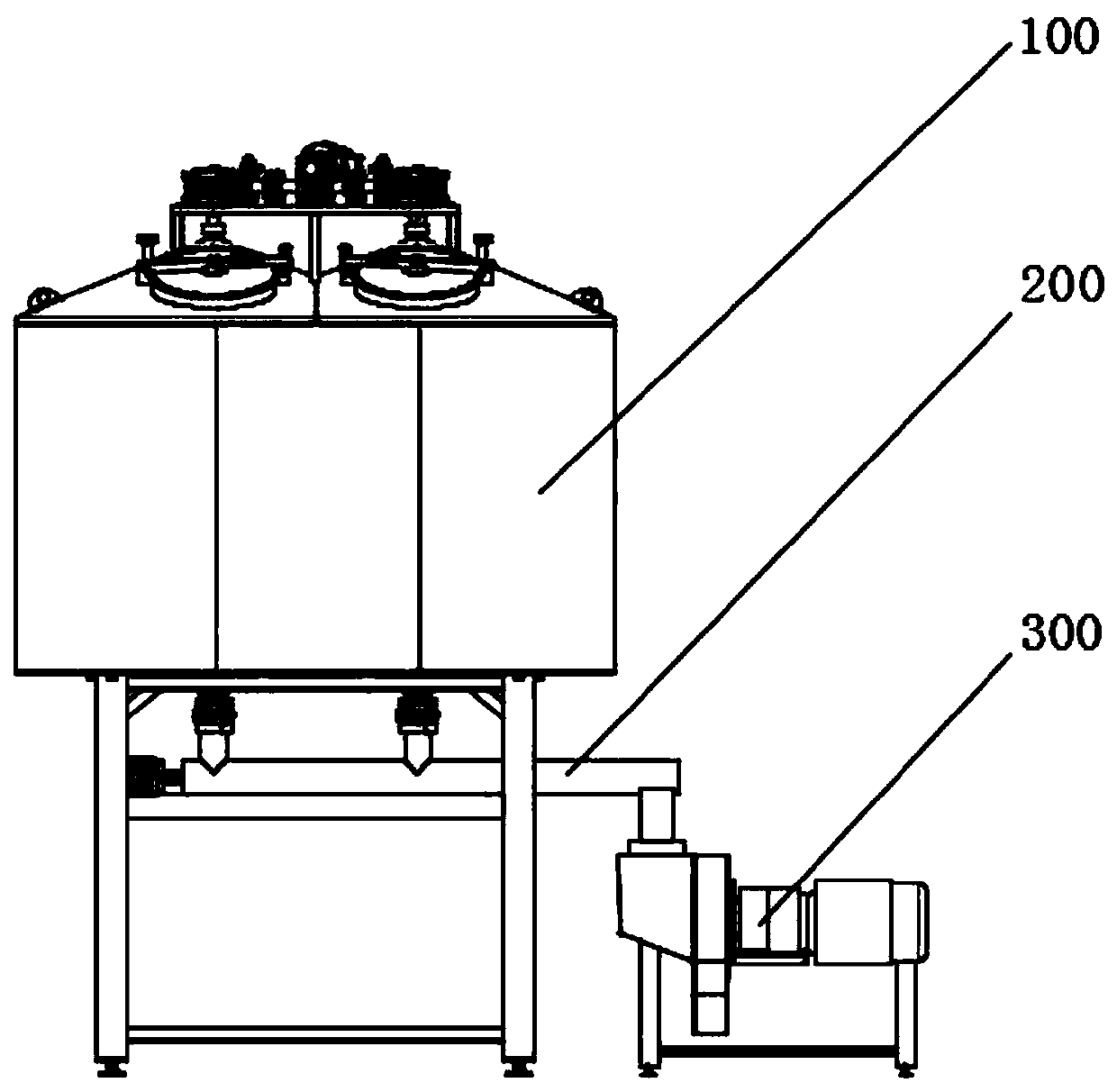

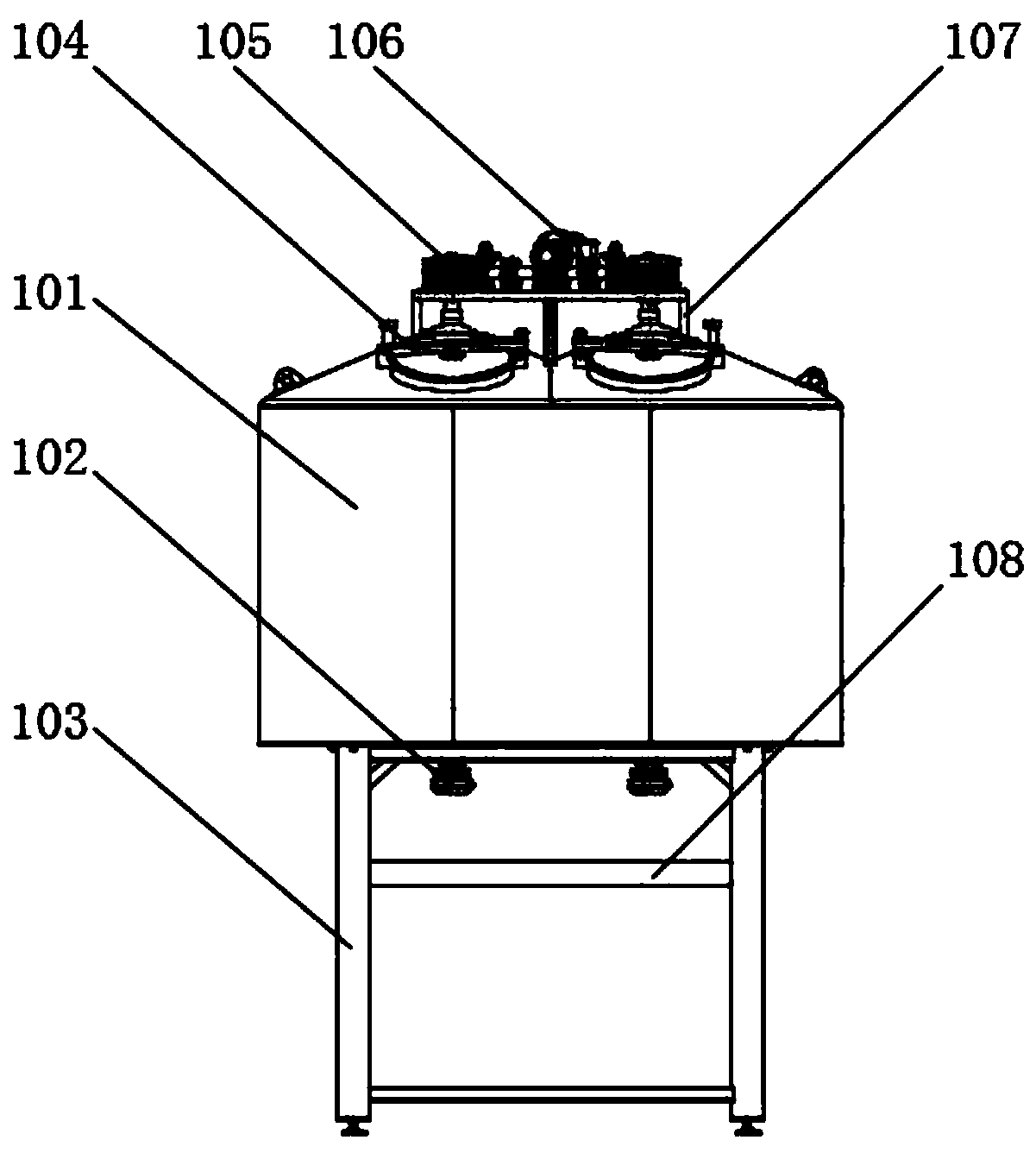

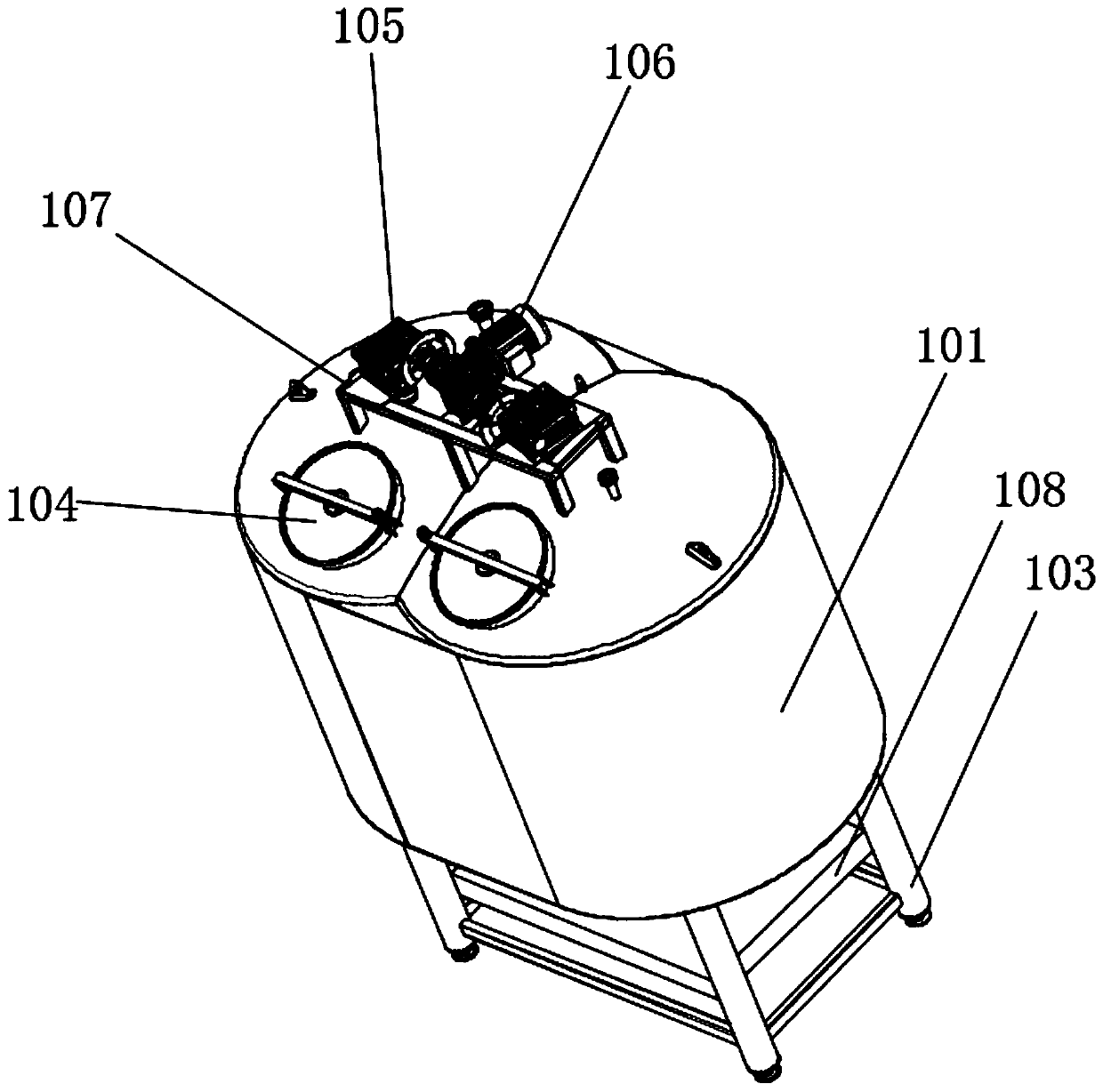

[0092] see Figure 1-11 As shown, the fertilizer mixing and granulating equipment in this embodiment includes a mixing and stirring mechanism 100, a conveying mechanism 200, and an extrusion and granulating mechanism 300. The inner cavity at the bottom of the mixing and stirring mechanism 100 is equipped with a conveying mechanism 200, and the conveying mechanism One end of 200 is connected to extrusion granulation mechanism 300;

[0093] The mixing mechanism 100 comprises a mixing bin 101, a first transmission case 105, a driving motor 106, a second transmission case 113, and an agitator 116, and the mixing bin 101 is installed on the top of a support frame 103, and the support frame 103 A support plate 108 is installed in the inner cavity, and a discharge pipe 102 is installed at both ends of the bottom of the mixing chamber 101, and the top of the discharge pipe 102 is connected to the inner cavity of the mixing chamber 101, and the top of the mixing chamber 101 A mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com