Movable type screening machine

A screening machine, mobile technology, applied in the direction of filtration, solid separation, and separation of solids from solids with airflow, can solve the problems of high cost, time-consuming and laborious installation and commissioning of equipment, and improve practicability and reliability Sexuality, convenient control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

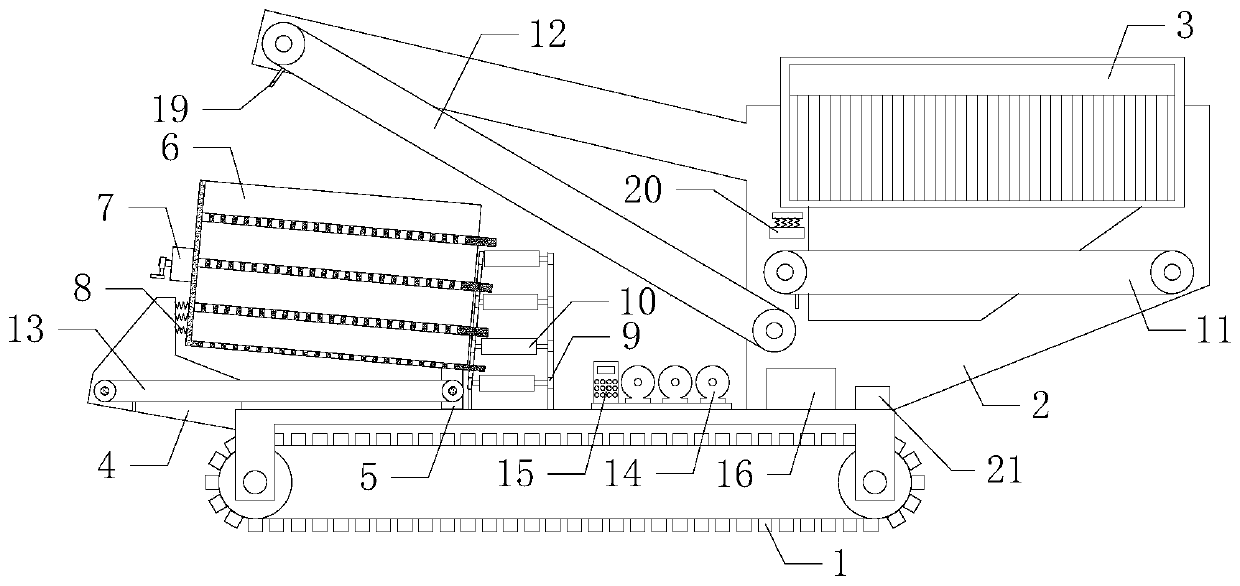

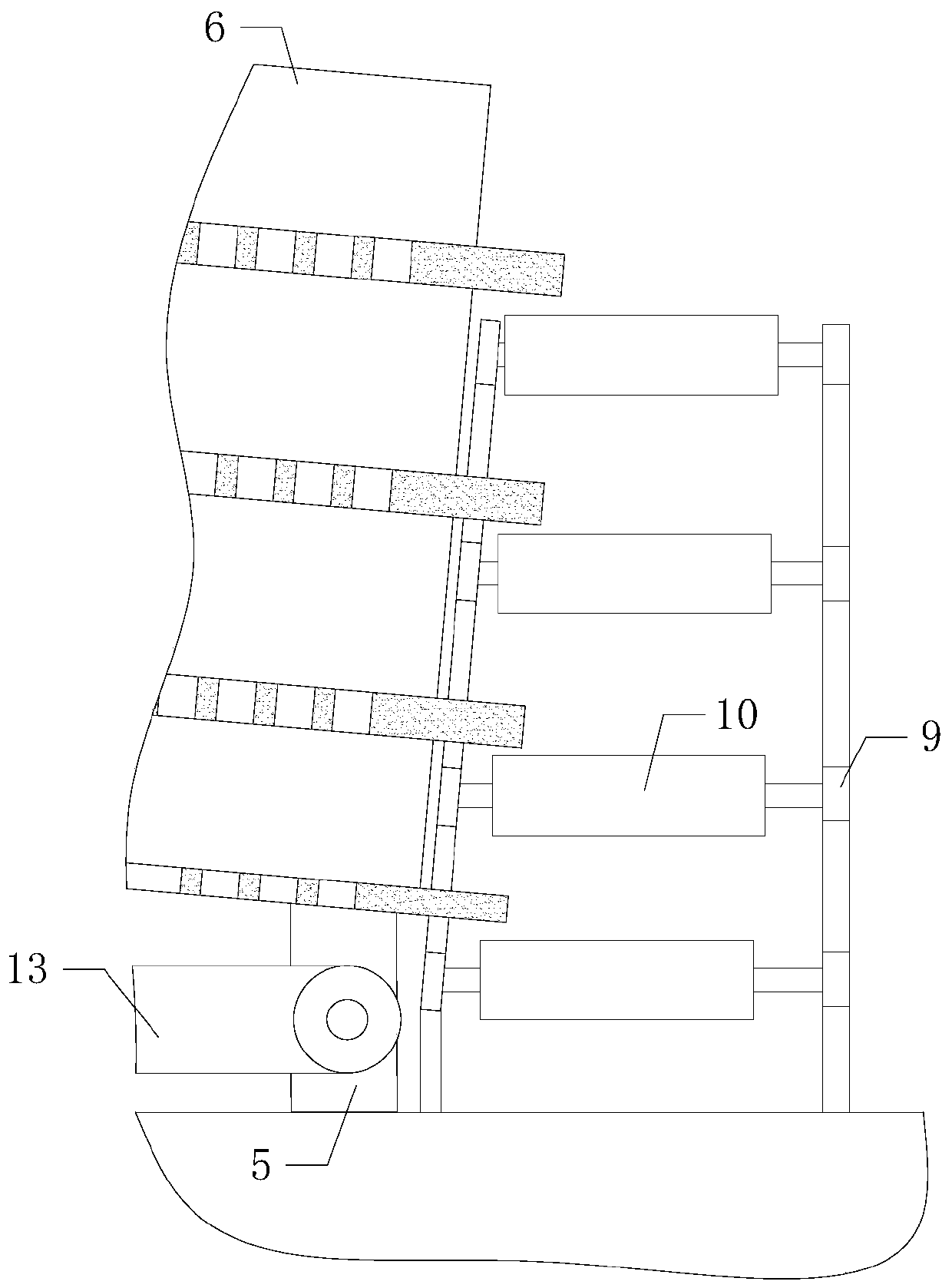

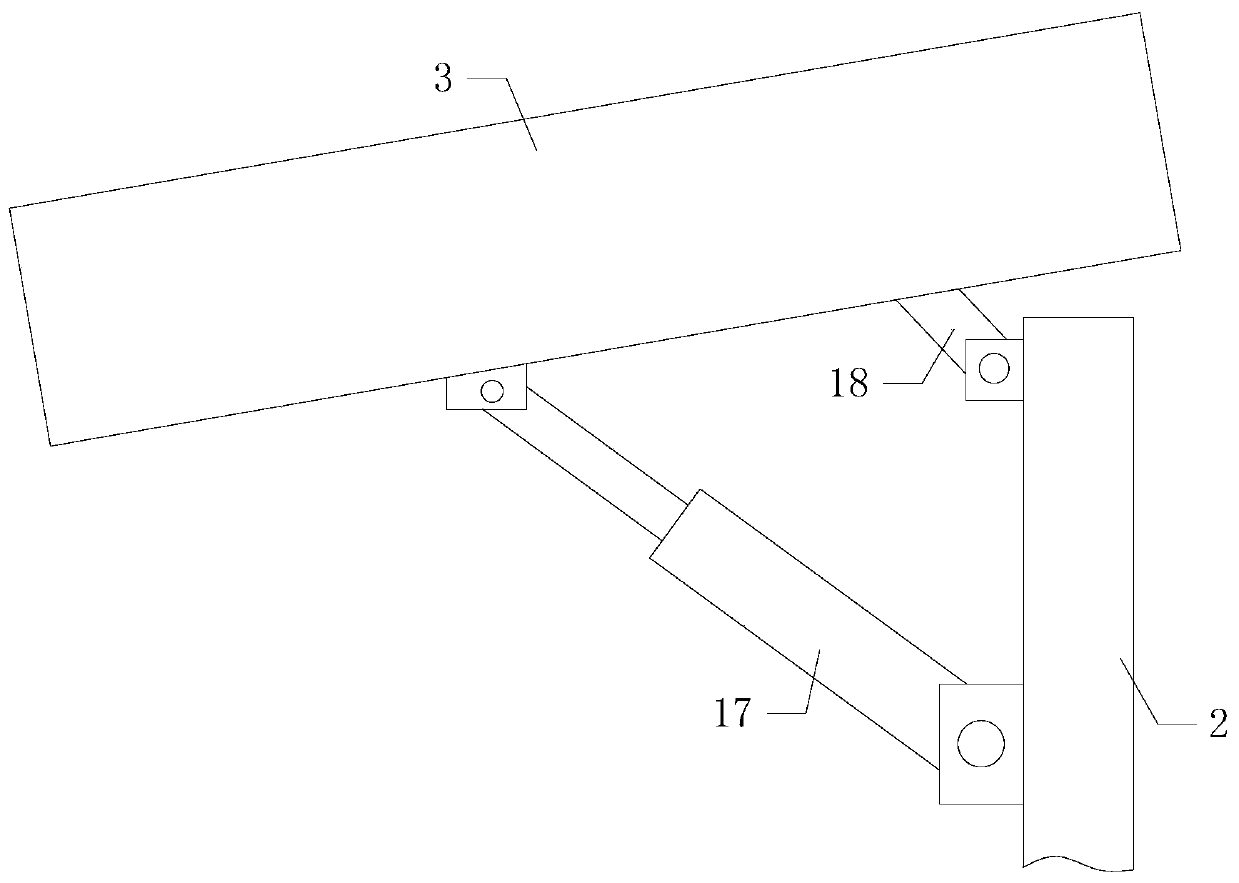

[0022] Such as Figure 1 to Figure 4 As shown, the mobile screening machine of the present invention, when it is working, opens the generator set 14, the generator set 14 can generate electric energy and supply the electric energy to the central control box 15, and the central control box 15 can control and open the crawler mobile vehicle 1 , vibrating machine 7, hydraulic folding conveyor 10, first conveyor 11, second conveyor 12 and third conveyor 13, the sand and gravel crushed by the external crusher are poured into the sieve plate 3 by the loader , the larger grains of gravel in the sieve plate 3 roll forward in the sieve plate 3 and break away from the sieve plate 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com