Coal washing wastewater treatment system

A treatment system and coal washing wastewater technology, which is applied in mining wastewater treatment, water/sewage treatment, biological water/sewage treatment, etc., can solve the problem that the actual effect of microbial flocculants cannot be fully utilized, the amount of microbial flocculants is large, and the impact of difficult coal washing wastewater and other problems, to achieve the effect of improving the sedimentation performance, reducing the cost of chemicals, and reducing the output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

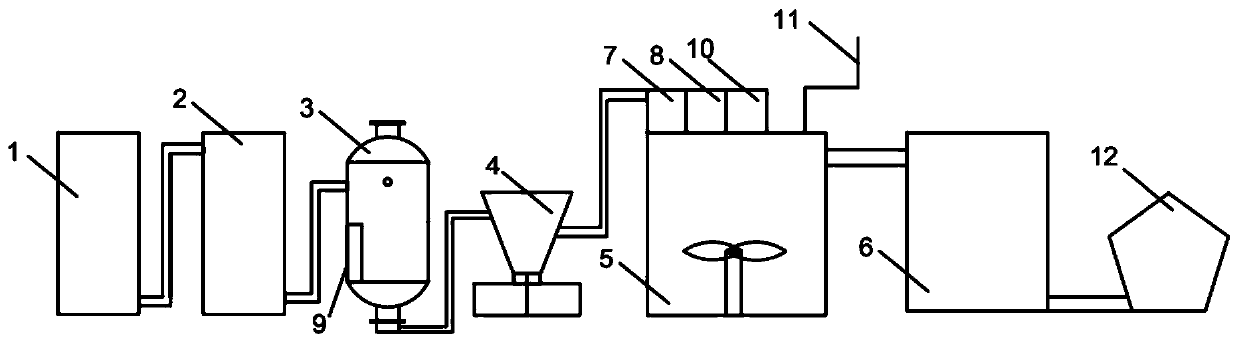

[0031] A coal washing wastewater treatment system, characterized in that the system includes an excess sludge bin 1, a freezing bin 2, a high-temperature steam wall breaking system 3, a centrifugal device 4, a flocculation treatment tank 5, and a solid-liquid separation device 6; The sludge bin 1 is connected to the freezing bin 2, and the remaining sludge is frozen in the freezing bin 2, and the frozen remaining sludge is transported to the high-temperature steam wall-breaking system 3, and high-temperature steam is introduced into the high-temperature steam wall-breaking system 3 for crushing. The sludge slurry is formed by the wall treatment, and the sludge slurry after the broken wall is transported to the centrifugal device 4, and the centrifuged supernatant is used as the excess sludge flocculant, and is transported to the excess sludge flocculant tank 7 for storage; The flocculation treatment tank 5 is provided with an excess sludge flocculant tank 7 and a lime suspensio...

Embodiment 2

[0042] Mine water quality and coal washing wastewater water quality are with embodiment 1;

[0043] Experimental condition is with embodiment 1;

[0044] The solid waste generated by the solid-liquid separation, the solid waste, after dehydration and drying, is added with caustic soda according to the mass ratio of 10:1, calcined and ground to 0.05-0.2mm, and the calcined product is added with hydrochloric acid solution and / or acid mine wastewater, adjust the pH to 3-5, stir under heating conditions for 60min, cool down to room temperature after the reaction is over, and remove the waste residue to obtain a solution containing polyaluminum iron calcium silicate; the polyaluminum iron calcium silicate Mixing the excess sludge flocculant with the excess sludge flocculant in a volume ratio of 5:30 to replace the excess sludge flocculant in step (4);

[0045] Effluent pH value: 8.07, SS: 89g / L, COD: 56mg / L.

Embodiment 3

[0047] Mine water quality and coal washing wastewater water quality are with embodiment 1;

[0048] Experimental condition is with embodiment 1;

[0049]The solid waste generated by the solid-liquid separation is dehydrated and dried, then calcined, and then the calcined residue is ball-milled to prepare a porous material with a particle size of 1-5mm, and the porous material is also added in the step 4 material, the calcination is carried out in a calcination furnace, the sintering temperature in the calcination furnace is 1250-1800°C, and the dosage of the porous material is 5-9g / L;

[0050] Effluent pH value: 7.93, SS: 98g / L, COD: 69mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com