Method for treating carboxylic acid-containing DMF in sucralose production

A technology of sucralose and processing method, which is applied in the field of food additives, can solve the problems of DMF decomposition, DMF loss, and difficult-to-handle solid salt slag, and achieve the effects of reducing operating temperature, avoiding decomposition, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

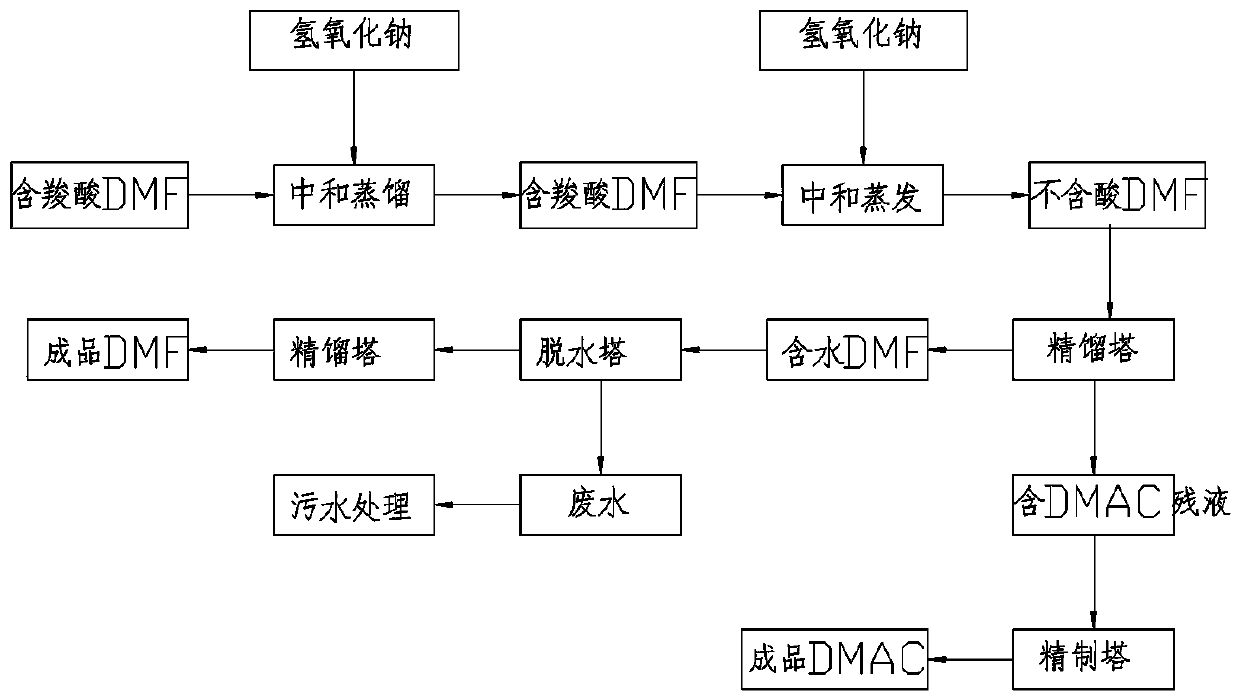

[0022] like figure 1 As shown, the acidic DMF containing acetic acid: 20wt%, DMF: 80wt% discharged from the bottom of the deacidification tower in the sucralose DMF recovery section is added to the preliminary evaporator, and 3% sodium hydroxide is added at the same time. Distillation and condensation (-0.098 MPa, 60-100℃) to obtain colorless and transparent DMF containing acetic acid.

[0023] Add the above DMF containing acetic acid into the neutralization evaporator (the neutralization evaporator is a kind of equipment with stirring and automatic discharge, which can realize the three functions of neutralization, evaporation concentration and solid discharge), and add equimolar ratio Sodium hydroxide makes the pH value of the reaction mixture to 7.0. After neutralizing the reactant, the material is water, DMF and sodium acetate, and then evaporates and concentrates (-0.098MPa, 60-100°C), and condenses the gas phase (the circulating water is condensed to 30- 50°C) to obtain...

Embodiment 2

[0029] Add the acidic DMF containing acetic acid: 15wt% and DMF: 85wt% discharged from the bottom of the deacidification tower in the sucralose DMF recovery section to the neutralization evaporator, and add 5% sodium hydroxide at the same time, distill and condense the colorless and transparent DMF containing acetic acid is added to the neutralization reaction evaporator, and sodium hydroxide in equimolar ratio is added to make the pH value of the reaction mixture reach 7.0. After neutralizing the reactant, the material is water, DMF and sodium acetate, and then evaporated and concentrated, and condensed in the gas phase To obtain acid-free DMF, the evaporator is high-purity sodium acetate; then the acid-free DMF obtained by gas phase condensation is sent to the rectification tower, and the top of the rectification tower is obtained including water, DMF and dimethylamine. , A bottom mixture comprising DMF, DMAC, and tetramethylurea was obtained at the bottom of the rectificatio...

Embodiment 3

[0032] Add the acidic DMF containing acetic acid: 18wt% and DMF: 82wt% discharged from the bottom of the deacidification tower in the sucralose DMF recovery section to the neutralization evaporator, and add 4% sodium hydroxide at the same time, distill and condense the colorless and transparent DMF containing acetic acid is added to the neutralization reaction evaporator, and sodium hydroxide in equimolar ratio is added to make the pH value of the reaction mixture reach 7.0. After neutralizing the reactant, the material is water, DMF and sodium acetate, and then evaporated and concentrated, and condensed in the gas phase To obtain acid-free DMF, the evaporator is high-purity sodium acetate; then the acid-free DMF obtained by gas phase condensation is sent to the rectification tower, and the top of the rectification tower is obtained including water, DMF and dimethylamine. , A bottom mixture comprising DMF, DMAC, and tetramethylurea was obtained at the bottom of the rectificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com