Degraded condensed tannin modified phenolic resin wood adhesive and preparation method thereof

A technology for wood adhesives and condensed tannins, applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesives, adhesive types, etc. Problems such as high cost increase and unsuitable synthesis of phenolic resin adhesives have achieved the effect of high-value and high-efficiency utilization, high industrial feasibility, and rapid curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

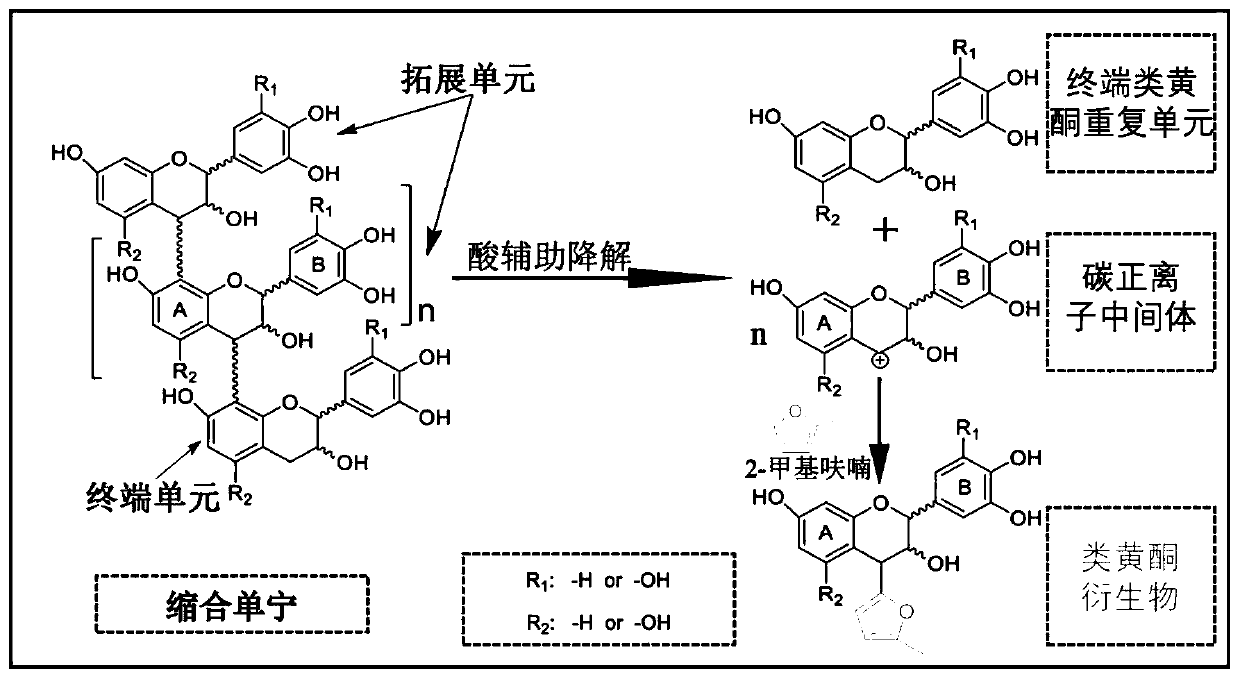

[0039] to combine figure 1 , a degraded condensed tannin modified phenolic resin wood adhesive and a preparation method thereof, comprising the following process steps:

[0040] Step 1, acid-assisted degradation of condensed tannins: mix the solvent and furan or furan derivatives uniformly according to the volume ratio of 2:1-4:1, preferably the volume ratio of solvent and furan or furan derivatives is 3:1; use hydrochloric acid Adjust the pH value of the mixed solution so that the concentration of hydrochloric acid is 0.1mol / L to obtain a condensed tannin degradation solution;

[0041] Step 2, mix the condensed tannins and the tannin degradation liquid evenly, when the concentration of the condensed tannins in the tannin mixed liquid is lower than 10g / L, then the preparation amount of the degraded condensed tannins is too low, the consumption of the degradation liquid is large, and the degraded The cost rises; when the concentration of condensed tannins is higher than 40g / L,...

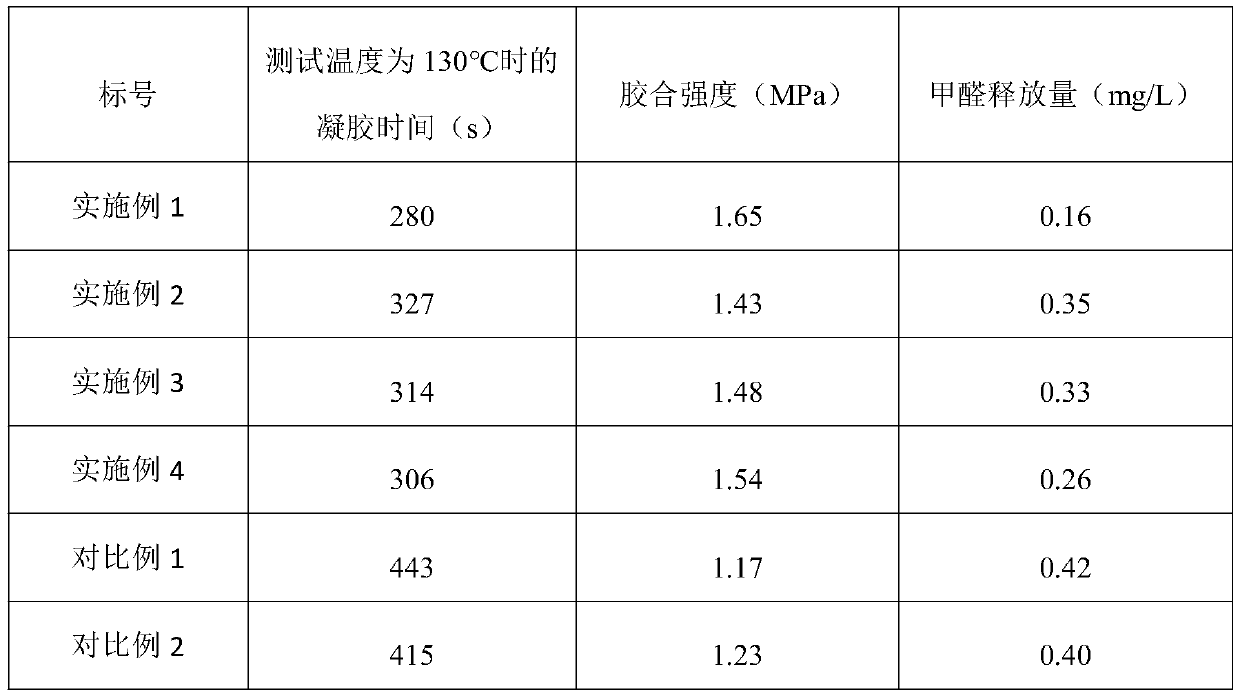

Embodiment 1

[0060] 1) Mix 600ml of methanol solvent and 200ml of 2-methylfuran evenly, adjust the pH value of the mixed solution with hydrochloric acid, so that the concentration of hydrochloric acid is 0.1mol / L, and obtain a condensed tannin degradation solution;

[0061] 2) Take 240g of acacia tannin and add it to the condensed tannin degradation solution;

[0062] 3) Degrade the Acacia tannin mixture at 50°C for 1.5 hours, then quickly add 12g / L sodium carbonate solution to raise the pH value of the tannin mixture to 8-9;

[0063] 4) Rotating the degraded acacia tannin mixture at normal temperature, and then washing it with water for 3-5 times;

[0064] 5) The acacia marzhan tannin washed with water was vacuum-dried at -60° C. for 24 hours to obtain degraded acacia marzhan tannin.

[0065] 6) Add 60g of phenol, 40g of distilled water, and 40g of NaOH solution (40%) into the flask, stir at 40°C for 10min, and the stirring speed is 300rpm;

[0066] 7) Add 95g of the first batch of form...

Embodiment 2

[0073] 1) Mix 600ml of ethanol solvent and 200ml of furan evenly, adjust the pH value of the mixed solution with hydrochloric acid, so that the concentration of hydrochloric acid is 0.1mol / L, and obtain the condensed tannin degradation solution;

[0074] 2) Take 240g of acacia tannin and add it to the condensed tannin degradation solution;

[0075] 3) Degrade the Acacia tannin mixture at 40°C for 2 hours, then quickly add 12g / L sodium carbonate solution to raise the pH value of the tannin mixture to 8-9;

[0076] 4) Rotating the degraded acacia tannin mixture at normal temperature, and then washing it with water for 3-5 times;

[0077] 5) The acacia marzhan tannin washed with water was vacuum-dried at -60° C. for 24 hours to obtain degraded acacia marzhan tannin.

[0078] 6) Add 60g of phenol, 40g of distilled water, and 40g of NaOH solution (40%) into the flask, stir at 40°C for 10min, and the stirring speed is 300rpm;

[0079] 7) Add 95g of the first batch of formaldehyde ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com