High-entropy-alloy-based self-lubricating composite and preparation method thereof

A high-entropy alloy and composite material technology, applied in the field of self-lubricating composite material preparation, can solve the problems of many solidification structure defects, high energy consumption, low performance, etc., and achieve the effect of avoiding solidification structure defects, excellent mechanical properties, and dense structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

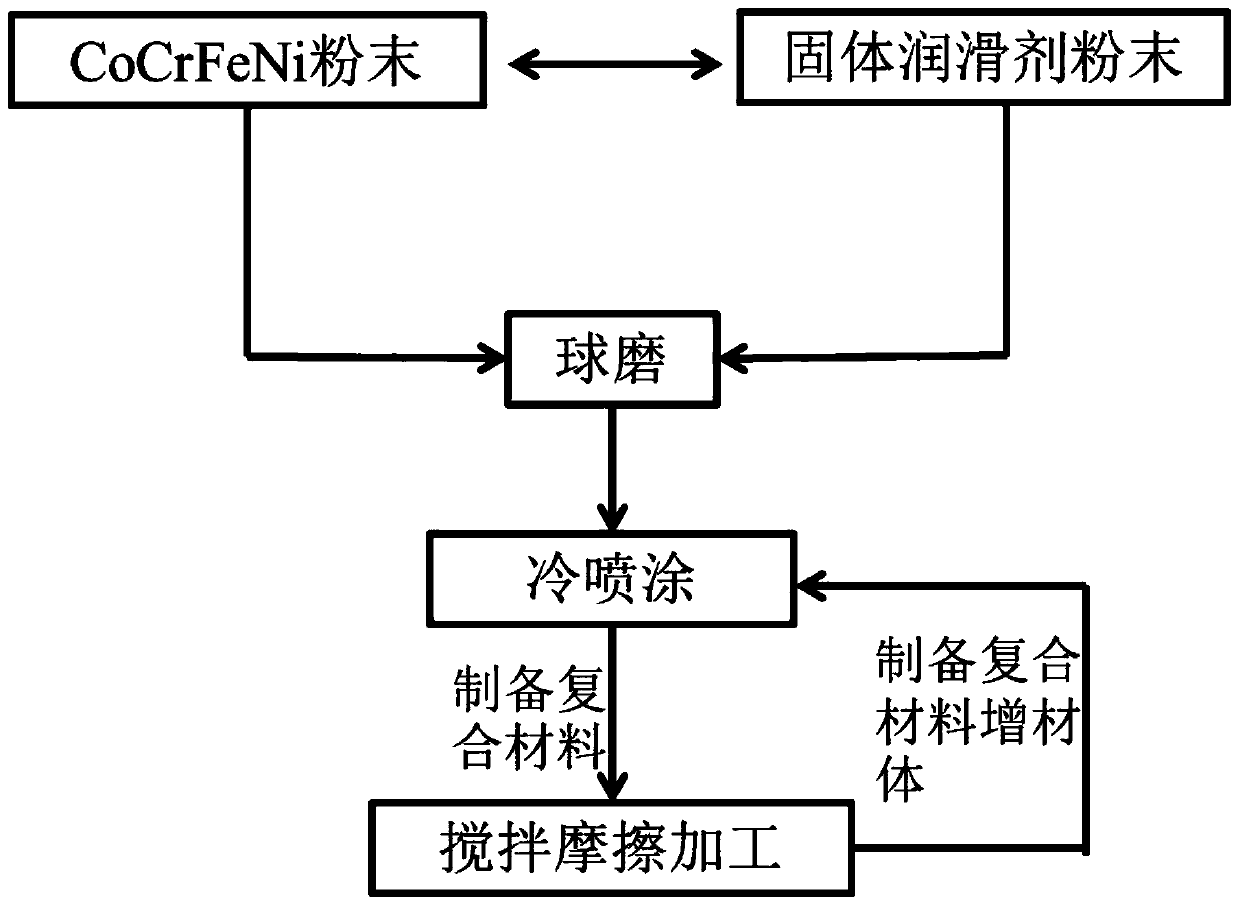

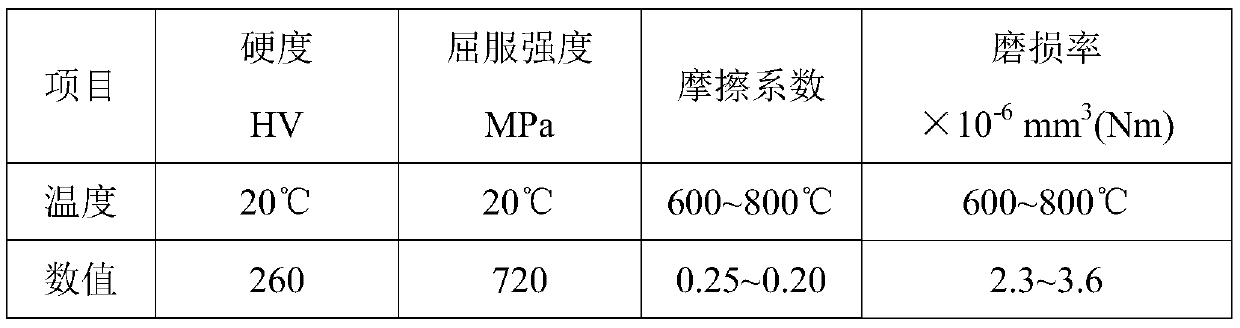

[0027] The present invention proposes a high-entropy alloy-based self-lubricating composite material and a preparation method thereof comprising: taking the quaternary high-entropy alloy CoCrFeNi as the matrix, and the solid lubricant as the lubricating phase, mixing CoCrFeNi and the solid lubricant by ball milling, and then using cold spraying Deposit on the metal substrate to form a deposit body, and then use a stirring head to perform friction stir processing on the deposit body to obtain a high-entropy alloy-based self-lubricating composite material. The mass ratio of the CoCrFeNi to the solid lubricant is (2.3-4 ):1.

[0028] The method specifically includes: weighing the CoCrFeNi powder and the solid lubricant powder, placing the weighed CoCrFeNi powder and the solid lubricant powder in a ball mill for full ball milling to make them evenly mixed. The ball-milled mixed powder is placed in the powder storage bin of the cold spray equipment to prepare the high-entropy alloy...

Embodiment 1

[0033] This example is to prepare 70% CoCrFeNi-30% MoS 2 Self-lubricating compound. 70%CoCrFeNi-30%MoS 2 It means that the mass percentage of CoCrFeNi in the composite material is 70%, MoS 2 The mass percentage is 30%, and concrete steps are as follows:

[0034] (1) According to CoCrFeNi and MoS 2 The mass ratio is 7:3, respectively weigh CoCrFeNi powder and MoS 2 powder, wherein the particle size distribution range of CoCrFeNi powder is 25-50 μm, and the purity is 99.6%; MoS 2 The particle size distribution range of the powder is 30-60 μm, and the purity is 99.5%.

[0035] (2) The weighed CoCrFeNi powder and MoS 2 The powder is placed in a ball mill for ball milling, the ball milling time is 3 hours, and the ball-to-material ratio is 3:1.

[0036](3) Place the ball-milled mixed powder in the powder storage bin of the cold spraying equipment for deposit preparation. The gas used for cold spraying is air, the spraying pressure is 3.5MPa, the gas preheating temperature is...

Embodiment 2

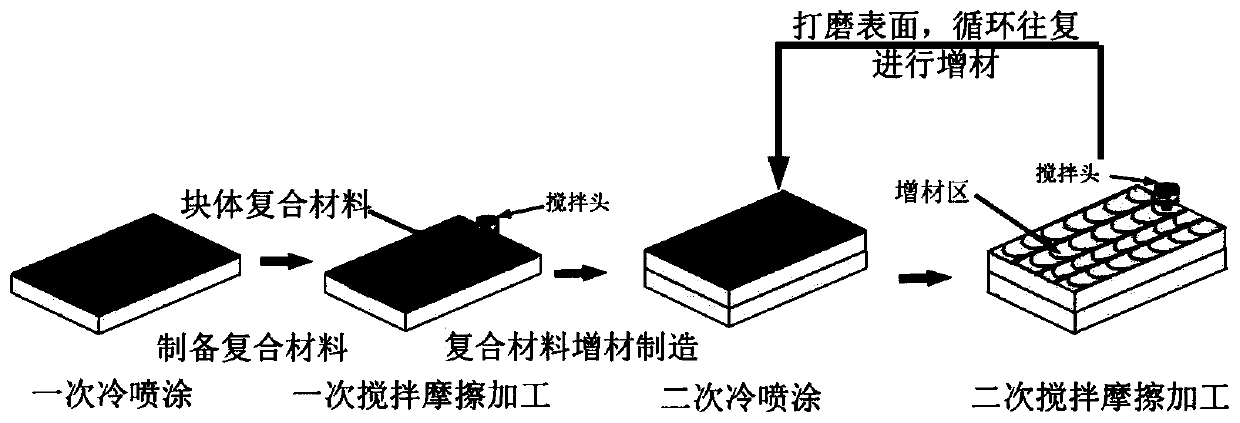

[0042] This example is to prepare 80% CoCrFeNi-20% MoS 2 Self-lubricating composite additive body. 80%CoCrFeNi-20%MoS 2 It means that the mass percentage of CoCrFeNi in the composite material is 80%, MoS 2 The mass percentage is 20%. In this embodiment, a thicker high-entropy alloy-based self-lubricating composite material additive body is prepared, and the steps of cold spraying and friction stir processing are repeated twice.

[0043] Specific steps are as follows:

[0044] (1) According to CoCrFeNi and MoS 2 The mass ratio is 4:1, respectively weigh CoCrFeNi powder and MoS 2 powder, wherein the particle size distribution range of CoCrFeNi powder is 25-50 μm, and the purity is 99.6%; MoS 2 The particle size distribution range of the powder is 30-60 μm, and the purity is 99.5%.

[0045] (2) The weighed CoCrFeNi powder and MoS 2 The powder is placed in a ball mill for ball milling, the ball milling time is 4 hours, and the ball-to-material ratio is 4:1.

[0046] (3) Pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com