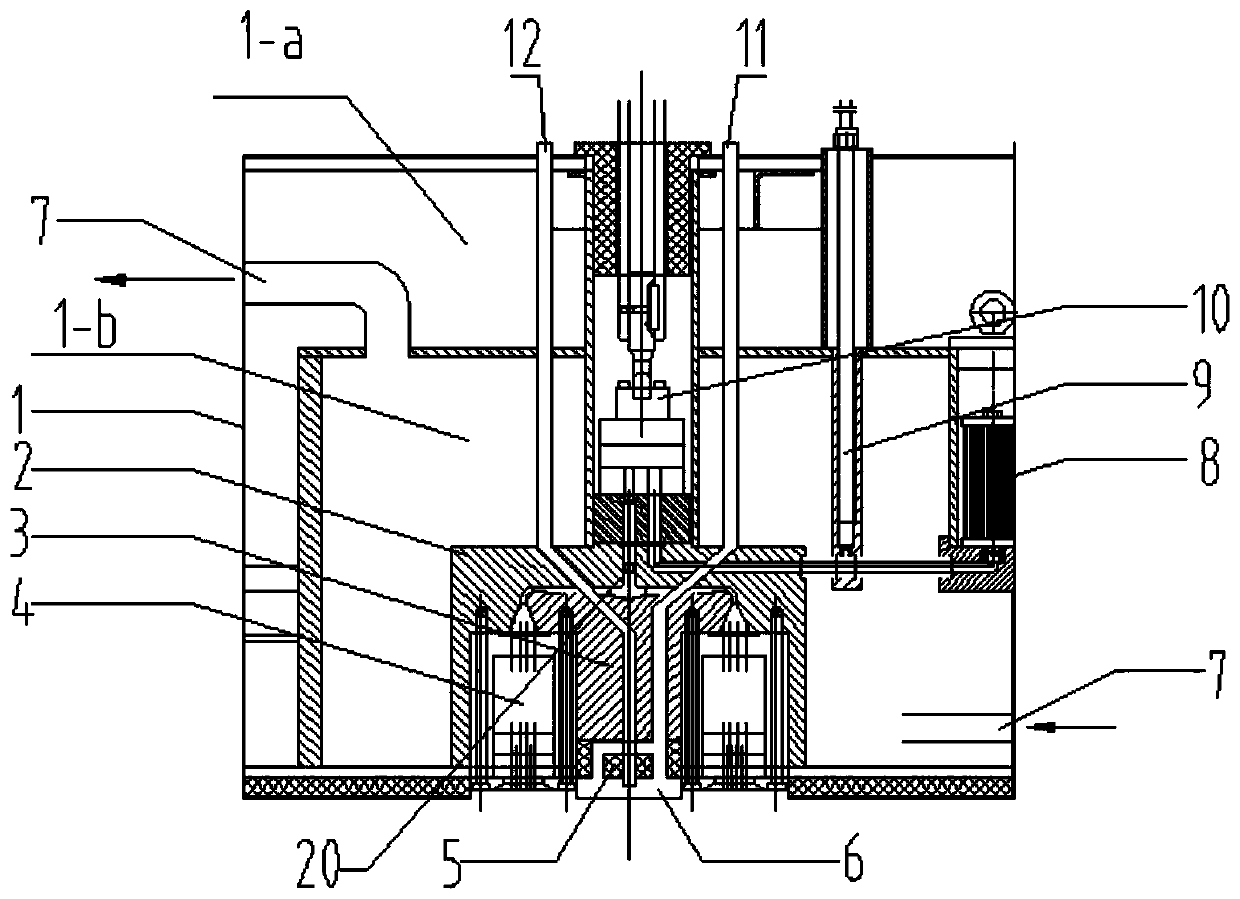

Large-tow continuous silicon carbide fiber preparation device and method

A silicon carbide fiber and preparation device technology, applied in fiber processing, fiber chemical characteristics, melt spinning, etc., can solve problems such as broken filaments and low wool filament efficiency, and achieve fiber wool reduction, low broken filament rate, and device uncomplicated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

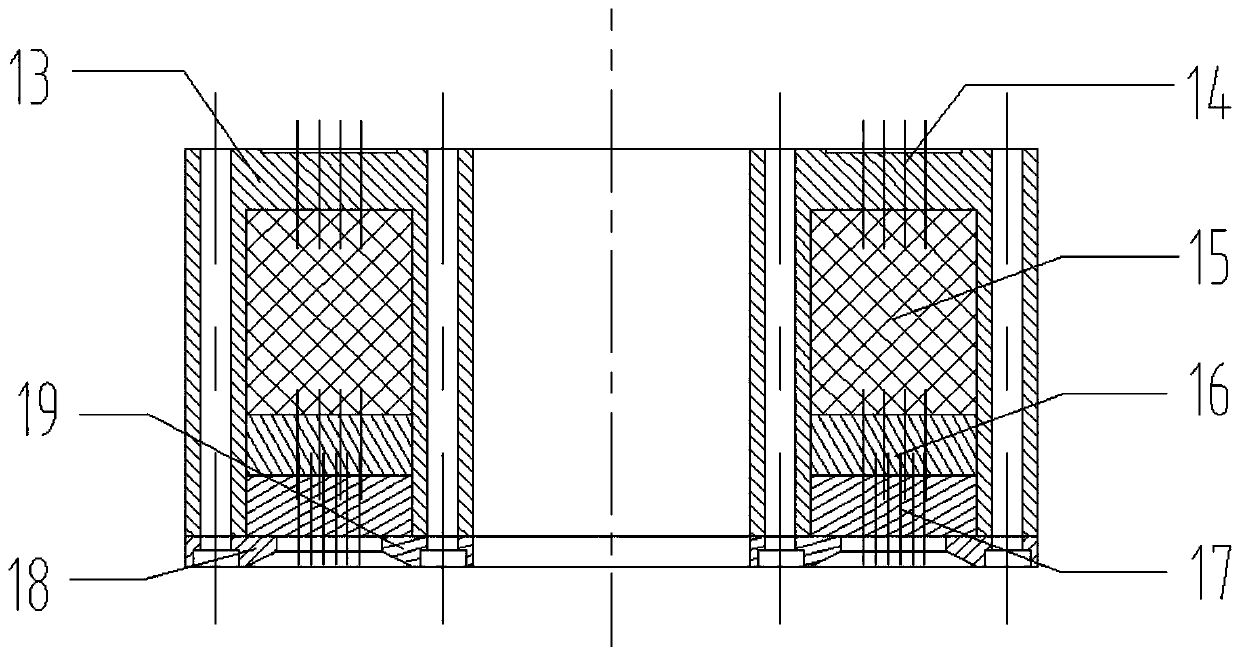

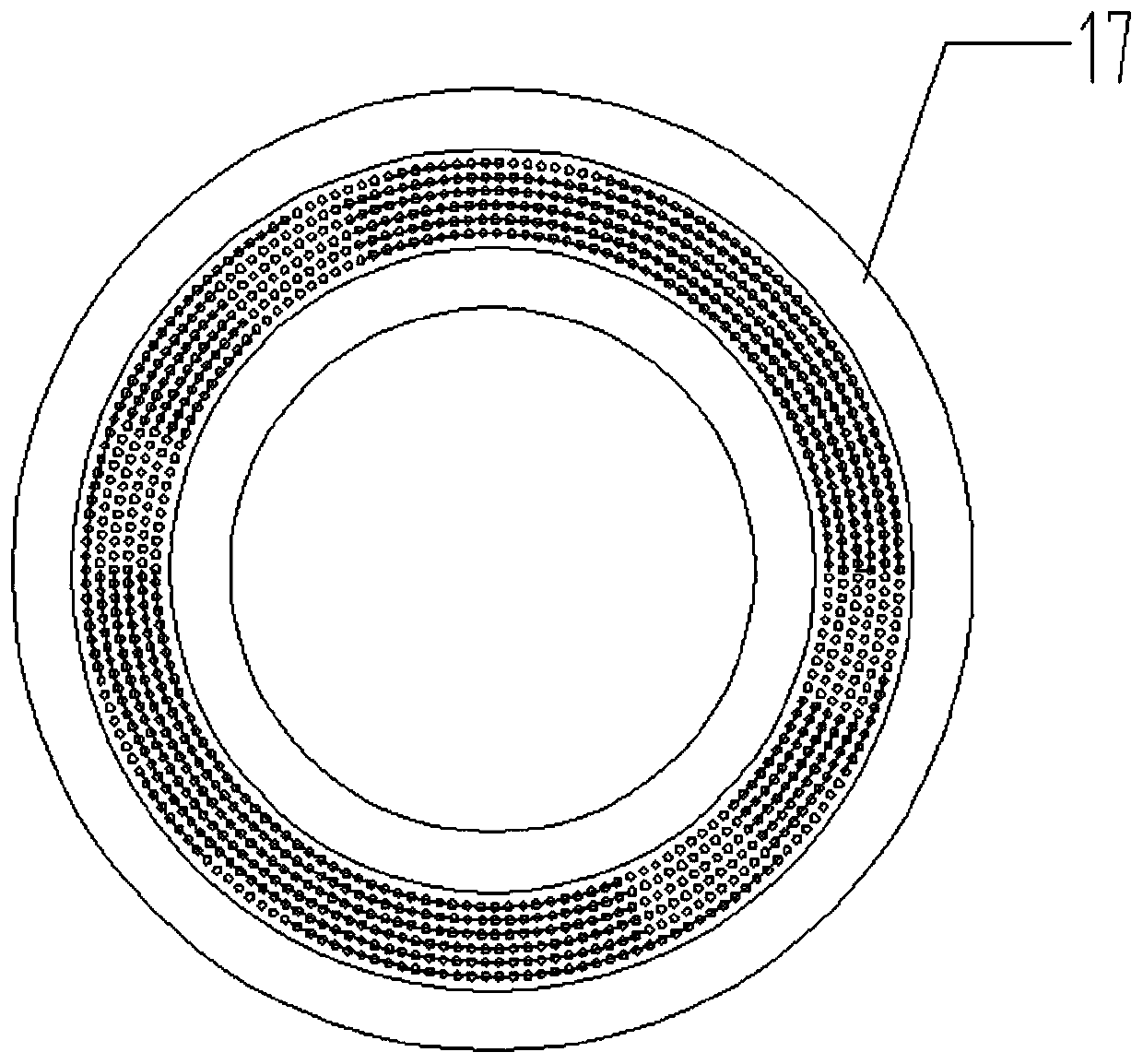

Embodiment 1

[0062] Put 40KG of spinning-grade polycarbosilane with a softening point of 210°C and an oxygen content of 0.4% into a melting kettle, vacuumize and replace nitrogen, and maintain a slight positive pressure of nitrogen; heat up to 400°C, vacuum defoaming; then cool down to a spinning temperature of 300°C ℃. The spinning assembly (the number of spinneret holes is 1000 holes, ring) is installed on the assembly base at the bottom of the spinning box, and the temperature of the spinning box and the spinning assembly is raised to a spinning temperature of 300 °C with heat transfer oil. Observe the temperature difference between the inner and outer rings of the spinneret. When the temperature difference is lower than 4°C, start spinning. During this period, turn on the airflow adjustment switch of the cooler, and automatically (or manually) adjust the airflow to keep the temperature difference between the inner and outer rings of the spinneret below 4°C. The PCS former silk that a...

Embodiment 2

[0070] Put 40KG of spinning-grade polycarbosilane with a softening point of 200°C and an oxygen content of 0.45% into a melting kettle, vacuumize to replace nitrogen, and maintain a slight positive pressure of nitrogen; raise the temperature to 400°C, vacuum defoaming; then cool down to the spinning temperature of 290 ℃. Install the spinning assembly (the number of spinneret holes is 1500, ring-shaped) on the assembly base at the bottom of the spinning box, and heat the spinning box and spinning assembly to a spinning temperature of 290° C. with heat transfer oil. Observe the temperature difference between the inner and outer rings of the spinneret. When the temperature difference is lower than 4°C, start spinning. During this period, turn on the airflow adjustment switch of the cooler, and automatically (or manually) adjust the airflow to keep the temperature difference between the inner and outer rings of the spinneret below 4°C. The PCS precursors prepared by the device o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com