Low-nitrogen combustion device for cement kiln tail

A low-nitrogen combustion and combustion device technology, applied in the direction of burners, combustion types, combustion methods, etc., can solve problems such as equipment installation space limitations, excessive fuel consumption, excessive ammonia escape, etc., to reduce fuel consumption and improve utilization , The effect of reducing the amount of pulverized coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0034] In order to specifically understand the technical solution provided by the present invention, the technical solution of the present invention will be described and explained in detail in the following embodiments. It is evident that the provided embodiments of the invention are not limited to specific details familiar to those skilled in the art. The preferred embodiments of the present invention are described in detail as follows. Apart from these descriptions, the present invention may also have other embodiments.

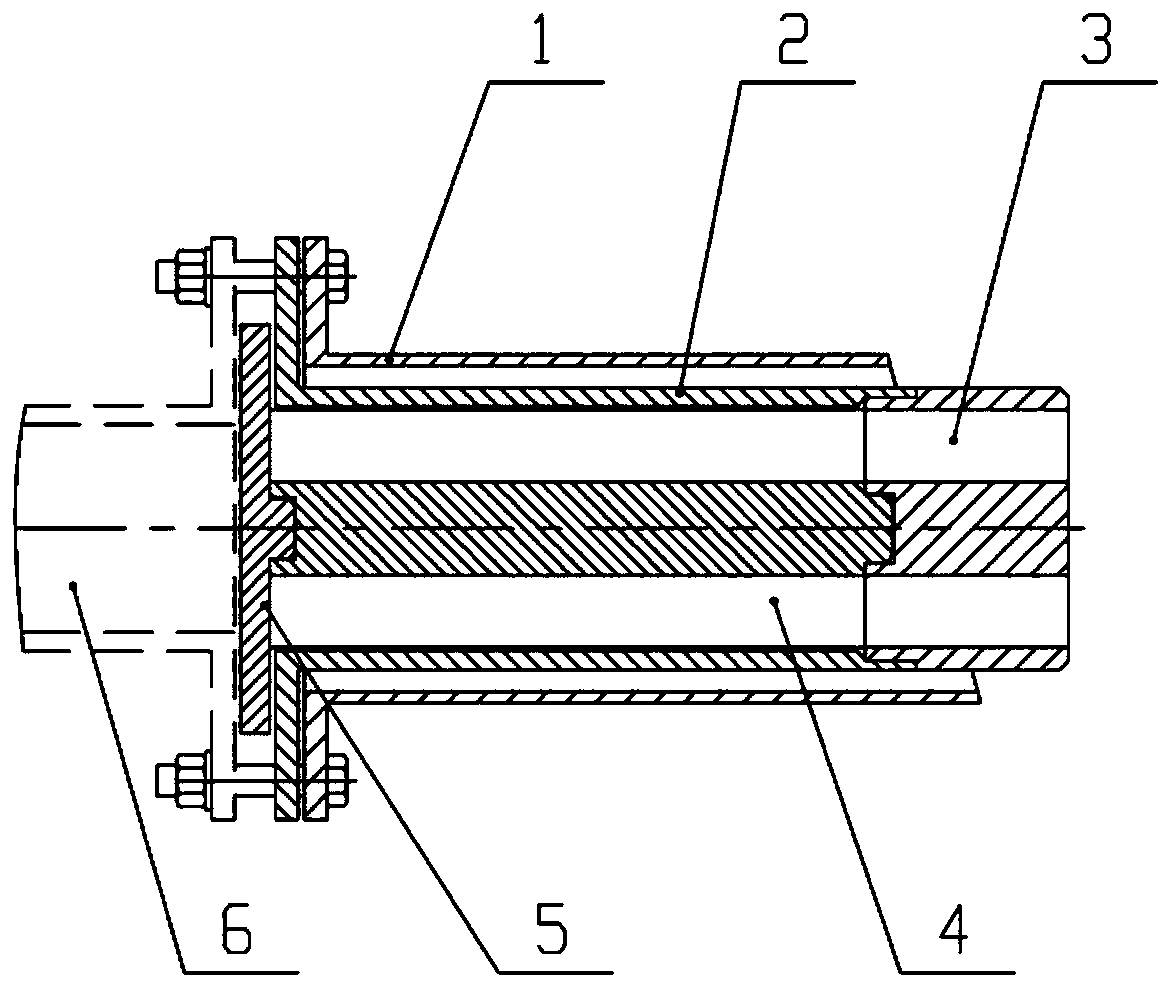

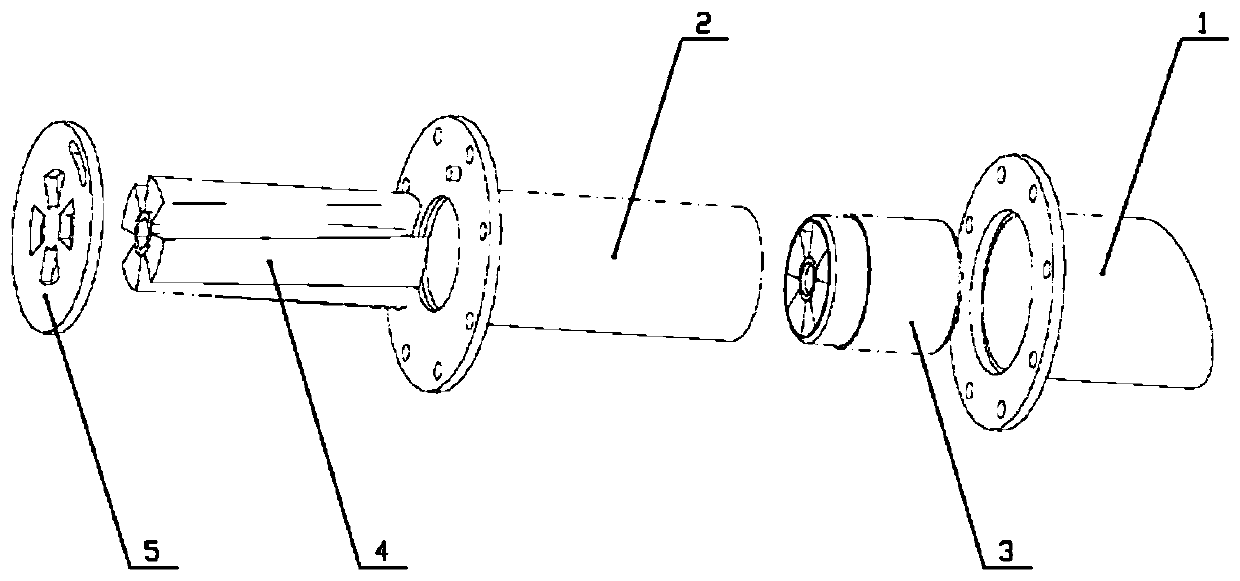

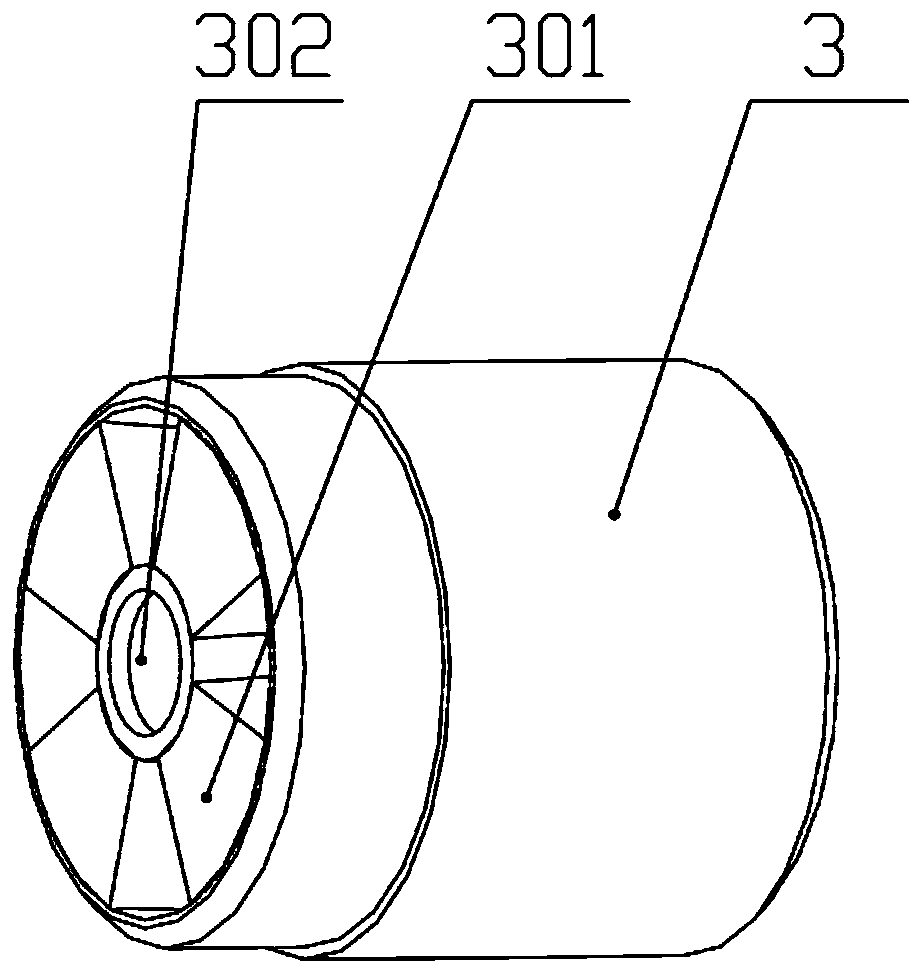

[0035] The invention provides a low-nitrogen combustion device for cement kiln tail, which is made of wear-resistant and high-temperature resistant stainless steel. Such as figure 2 As shown, two sets of low-nitrogen combustion devices for cement kiln tail need to be installed, so there are two combustion de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Twist angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com