Magnetic core and preparation method thereof, inductor and filter

A magnetic core and winding technology, which is used in inductors with magnetic cores, magnetic core manufacturing, transformer/inductor magnetic cores, etc., can solve the problems of EMI filter magnetic core selection and targeted production difficulties, and reduce Volume and complexity, reduced eddy current loss, beneficial effect of post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

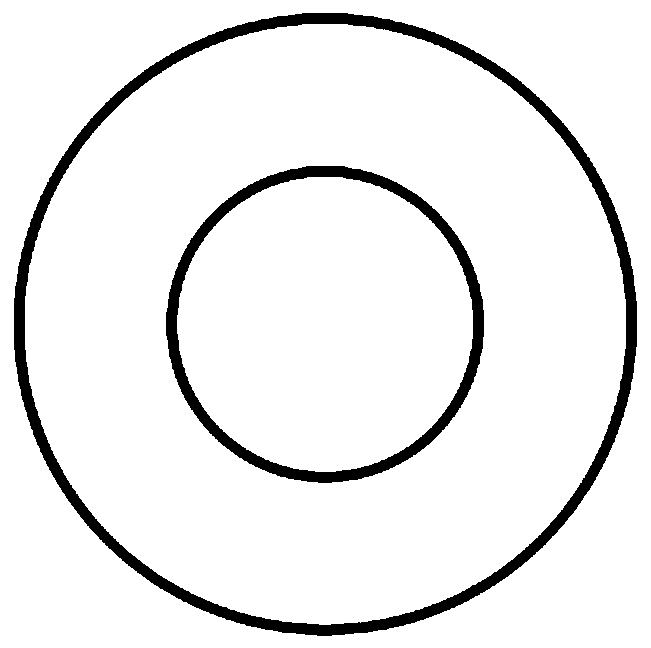

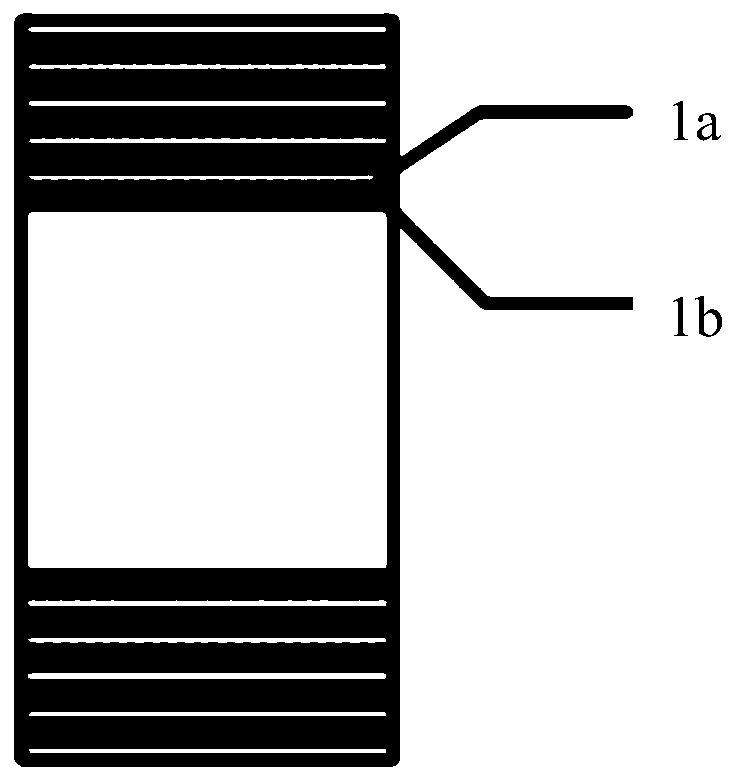

[0123] In a fourth aspect, the present application provides a method for preparing a magnetic core, the magnetic core is the magnetic core as described above, and the preparation method includes:

[0124] Provide a magnetic tape and an adhesive layer, and laminate the magnetic tape and the adhesive layer to obtain a composite magnetic material layer;

[0125] unitizing at least one of the composite magnetic material layers;

[0126] A plurality of the composite magnetic material layers are laminated and then wound, wherein at least two of the composite magnetic material layers have different magnetic properties.

[0127] The preparation method of the magnetic core is composed of layered composite magnetic materials with different properties, which can meet the anti-EMI requirements of different power ranges and frequency ranges. In the method, a plurality of composite magnetic materials are stacked together, and then can be wound. The method has the characteristics of simple ...

Embodiment 1

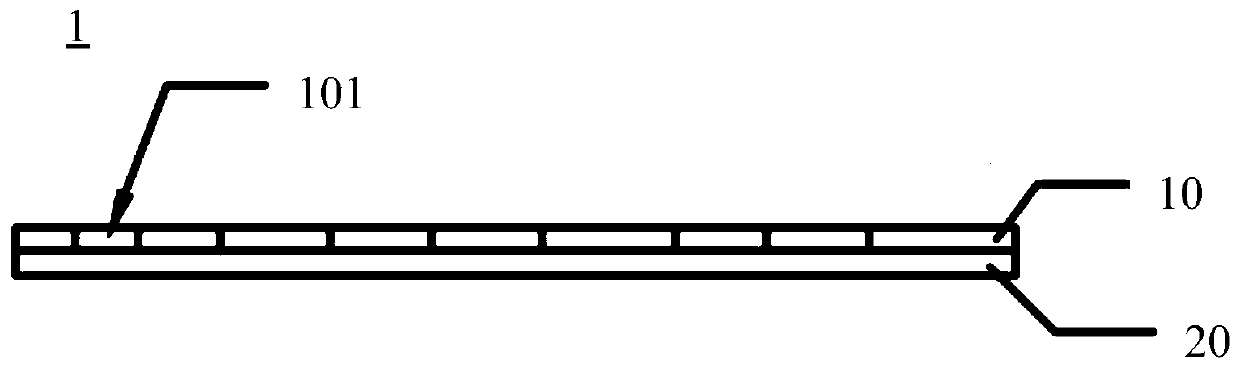

[0155] The commercially available 1k107B nanocrystalline ribbon (thickness 20μm±2μm, width 10mm) was used as raw material to produce filter inductor cores. Specifically include the following steps:

[0156] S1: Divide the raw strip into small rolls of 300m±50m, put them into a heat treatment furnace for heat treatment.

[0157] S2: Heat treatment system: heat up to 560°C at a heating rate of 2°C / min, then hold for 90 minutes, then cool naturally to 200°C, then take it out of the furnace and cool to room temperature. During the whole heat treatment process, nitrogen with a purity of more than 99.999% is used as the protective atmosphere.

[0158] S3: The relative magnetic permeability of the material after heat treatment reaches 13000~20000@100kHz;

[0159] S4: One side of the heat-treated magnetic strip is coated with a PET film coated with an acrylic adhesive on one side, and the total thickness of the film is 5 μm±1 μm.

[0160] S5: Use 40-mesh anilox rollers for unitized...

Embodiment 2

[0171] The commercially available 1k107B nanocrystalline ribbon (thickness 20μm±2μm, width 10mm) was used as raw material to produce filter inductor cores.

[0172] S1: Divide the raw strip into small rolls of 300m±50m, put them into a heat treatment furnace for heat treatment.

[0173] S2: Heat treatment system: heat up to 560°C at a heating rate of 2°C / min, then hold for 90 minutes, then cool naturally to 200°C, then take it out of the furnace and cool to room temperature. During the whole heat treatment process, nitrogen with a purity of more than 99.999% is used as the protective atmosphere.

[0174] S3: The relative magnetic permeability of the material after heat treatment reaches 13000~20000@100kHz;

[0175] S4: One side of the heat-treated magnetic strip is coated with a PET film coated with an acrylic adhesive on one side, and the total thickness of the film is 5 μm±1 μm.

[0176] S5: Use 40-mesh anilox rollers for unitized operation to reduce the relative magnetic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com