C70 self-compacting concrete and preparation method thereof

A technology for self-compacting concrete and mixture, applied in the field of concrete, can solve the problems of incomplete functioning, reduced concrete fluidity, influence of concrete workability, etc., and achieves the effects of improving workability, improving compactness, and reducing drying shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

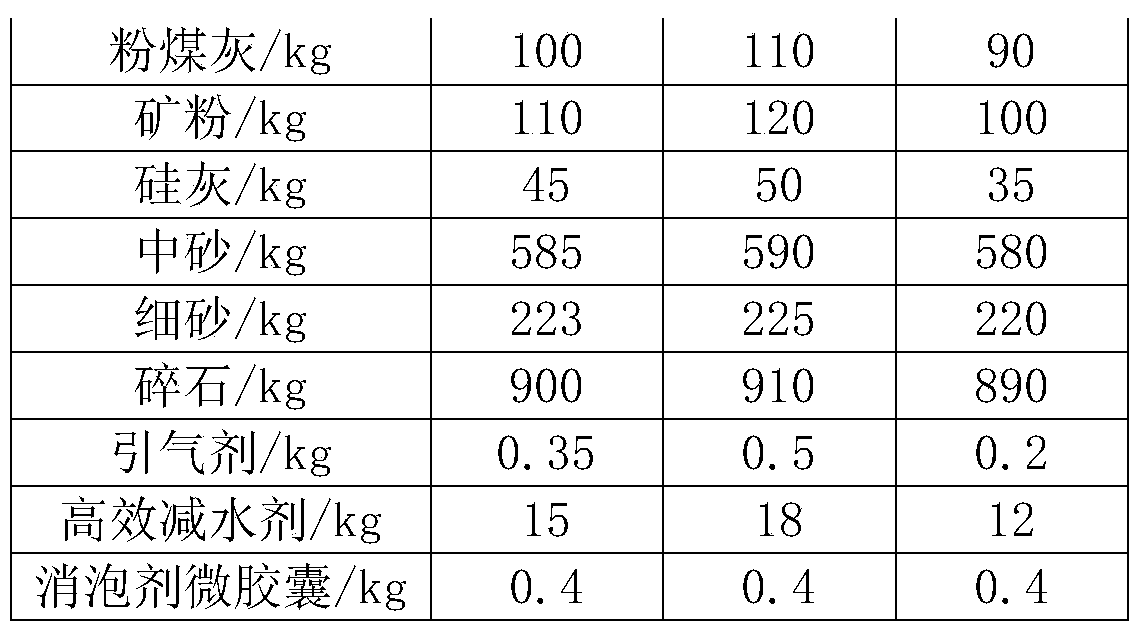

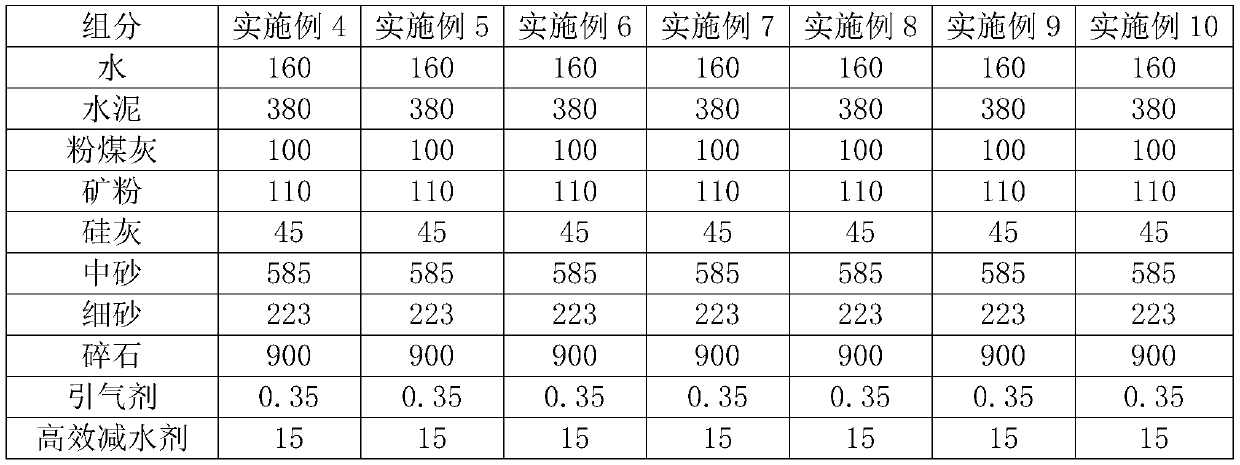

Method used

Image

Examples

preparation example Construction

[0052] Preparation example of defoamer microcapsules

[0053] The defoamers involved in the following preparation examples are PW-03 concrete powder defoamers from Nanhai Datian Chemical Co., Ltd., Foshan City; β-cyclodextrin and gum arabic are all collected from Xi'an Lavia Biotechnology Co., Ltd.

preparation example 1

[0054] Preparation Example 1: Antifoaming agent microcapsules are prepared through the following steps:

[0055] S1: Add 1.5kg of β-cyclodextrin to 45kg of water, add a heating mixer and stir until the β-cyclodextrin dissolves, set the stirring temperature at 55°C, then add 15kg of gum arabic and continue stirring until completely dissolved. Form solution A;

[0056] S2: The powder defoamer with a weight of 5 kg is used as a seed crystal, solution A is used as a spray, and spray-dried using a spray dryer, and the semi-dry capsules formed by spray drying are dried at room temperature to form crude defoamer microcapsules;

[0057] S3. Sieving the crude defoamer microcapsules with an 8-mesh sieve to obtain defoamer microcapsules.

preparation example 2

[0058] Preparation Example 2: Antifoaming agent microcapsules are prepared through the following steps:

[0059] S1: Add 25kg of β-cyclodextrin to 50kg of water, add a heating mixer and stir until the β-cyclodextrin dissolves, set the stirring temperature at 58°C, then add 16.5kg of gum arabic and continue stirring until completely dissolved. Form solution A;

[0060] S2: The powder defoamer with a weight of 20 kg is used as a seed crystal, solution A is used as a spray, and spray-dried using a spray dryer, and the semi-dry capsules formed by spray drying are dried at room temperature to form crude defoamer microcapsules;

[0061] S3. Sieving the crude defoamer microcapsules with an 8-mesh sieve to obtain defoamer microcapsules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com