Fe-doped CuAlO2 high-temperature wave-absorbing ceramic and preparation method thereof

A high-temperature, ceramic technology, which is applied in the field of Fe-doped CuAlO2 high-temperature microwave-absorbing ceramics and its preparation, can solve the problems of reduced microwave-absorbing performance, high price, and oxidation of carbon materials, and achieve control of investment, good application and promotion, and good industrialization The effect of applying value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

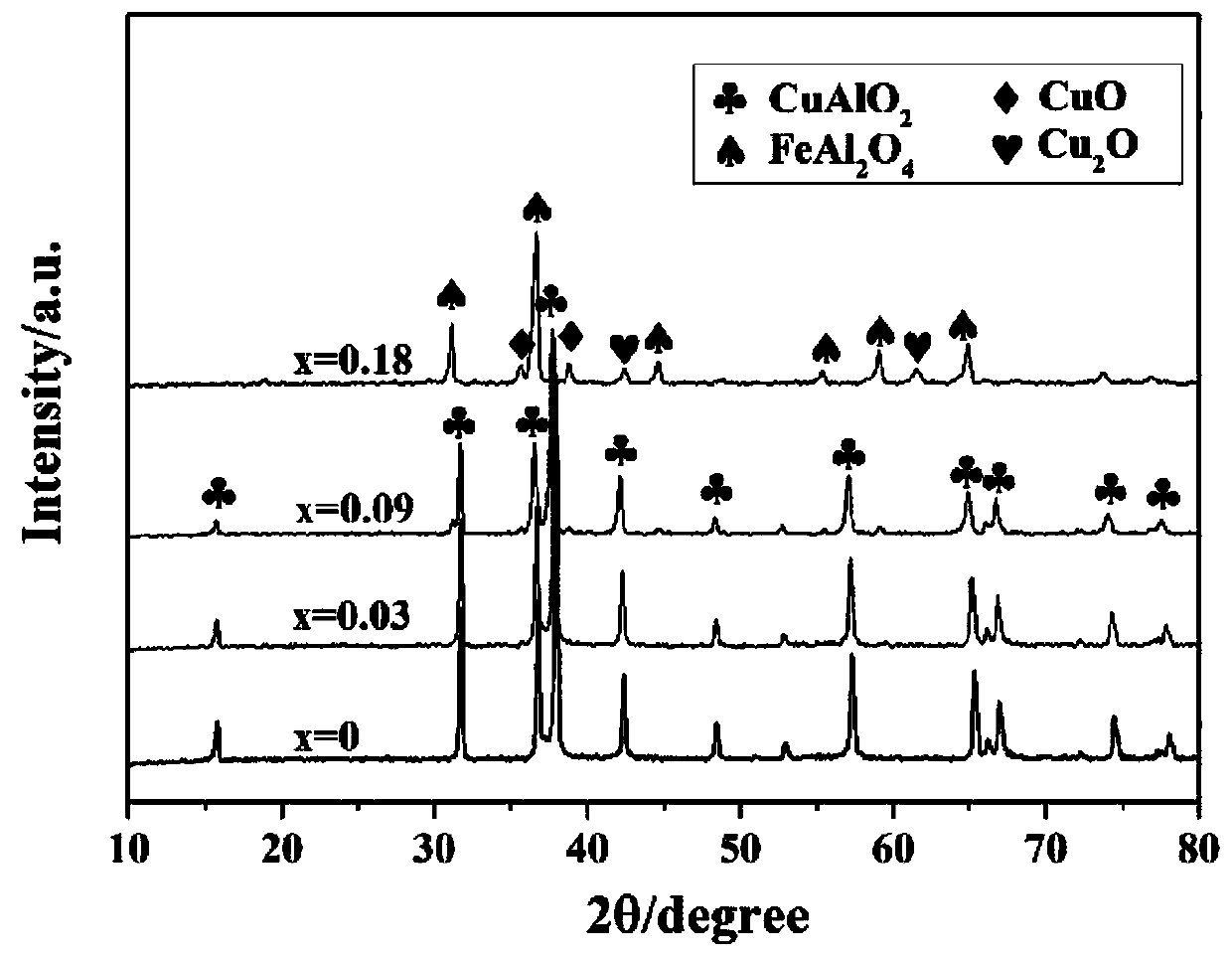

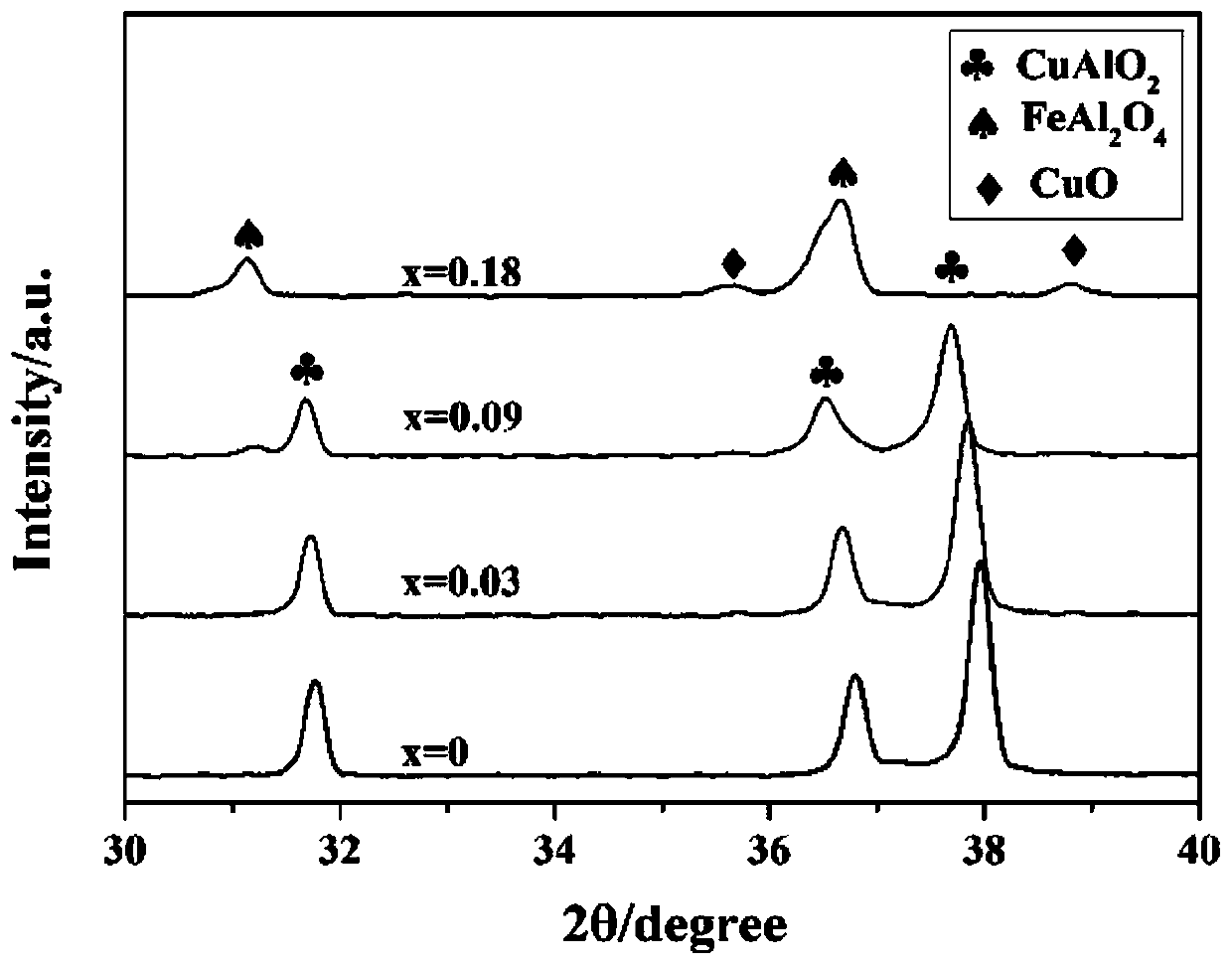

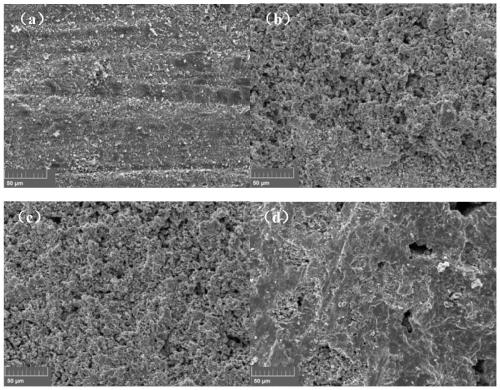

[0037] The purpose of the embodiments of the present invention is to provide a high-temperature wave absorbing ceramic with cheap raw materials and low preparation cost and a preparation method thereof, the chemical formula of which is CuAlO 2 .

[0038] Step 1: Preparation of CuAlO 2 high temperature absorbent

[0039] First, the stoichiometric ratio of 0.5:1 Cu 2 O, Al(OH) 3 The raw materials are thoroughly mixed and uniform, then pre-fired at high temperature and cooled with the furnace.

[0040] CuAlO 2 The preparation method of high temperature absorbent is carried out according to the following steps:

[0041] S1, Weighing: Weigh Cu according to the stoichiometric ratio 2 O, Al(OH) 3 ;

[0042] S2, ball milling: the weighed Cu 2 O, Al(OH) 3 Pour it into a ball mill jar and add grinding balls, deionized water and anhydrous ethanol, and then ball-mill;

[0043] S3, drying: after the ball milling is completed, the absolute ethanol of the mixed slurry in the ball ...

Embodiment 2

[0053] The purpose of the embodiments of the present invention is to provide a high-temperature wave absorbing ceramic with cheap raw materials and low preparation cost and a preparation method thereof, the chemical formula of which is CuAl 0.97 Fe 0.03 O 2 .

[0054] Step 1: Preparation of CuAl 0.97 Fe 0.03 O 2 high temperature absorbent

[0055] First, the Cu with a stoichiometric ratio of 0.5:0.97:0.03 2 O, Al(OH) 3 , Fe(OH) 3 The raw materials are thoroughly mixed and uniform, then pre-fired at high temperature and cooled with the furnace.

[0056] CuAl 0.97 Fe 0.03 O 2 The preparation method of high temperature absorbent is carried out according to the following steps:

[0057] S1, Weighing: Weigh Cu according to the stoichiometric ratio 2 O, Al(OH) 3 and Fe(OH) 3 ;

[0058] S2, ball milling: the weighed Cu 2 O, Al(OH) 3 and Fe(OH) 3 Pour it into a ball mill jar and add grinding balls, deionized water and anhydrous ethanol, and then ball-mill;

[0059]...

Embodiment 3

[0069] The purpose of the embodiments of the present invention is to provide a high-temperature wave absorbing ceramic with cheap raw materials and low preparation cost and a preparation method thereof, the chemical formula of which is CuAl 0.91 Fe 0.09 O 2 .

[0070] Step 1: Preparation of CuAl 0.91 Fe 0.09 O 2 high temperature absorbent

[0071] First, put Cu with a stoichiometric ratio of 0.5:0.91:0.09 2 O, Al(OH) 3 , Fe(OH) 3 The raw materials are thoroughly mixed and uniform, then pre-fired at high temperature and cooled with the furnace.

[0072] CuAl 0.91 Fe 0.09 O 2 The preparation method of high temperature absorbent is carried out according to the following steps:

[0073] S1, Weighing: Weigh Cu according to the stoichiometric ratio 2 O, Al(OH) 3 and Fe(OH) 3 ;

[0074] S2, ball milling: the weighed Cu 2 O, Al(OH) 3 and Fe(OH) 3 Pour it into a ball mill jar and add grinding balls, deionized water and anhydrous ethanol, and then ball-mill;

[0075]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com