MXene/ink high-sensitivity sensor free of high-valence metal ions and preparation method thereof

A high-priced metal ion, high-sensitivity technology, applied in the field of sensors, can solve the problems of viscosity increase, ink property influence, sensor sensitivity and data accuracy, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

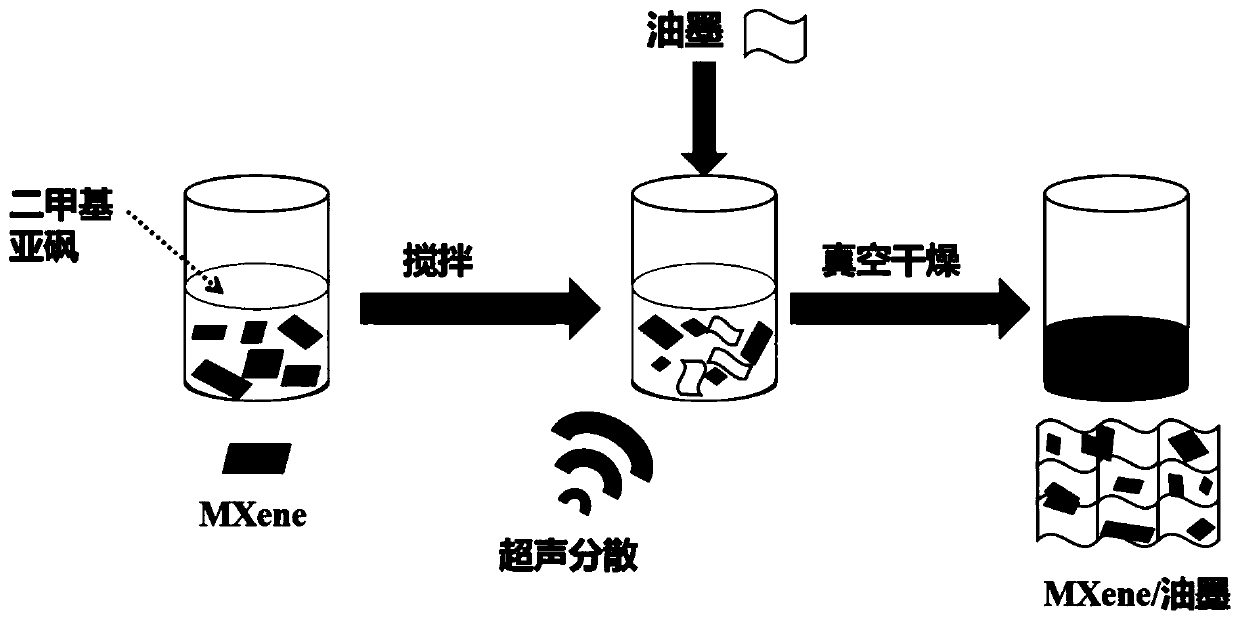

[0065] Weigh 0.1 g of MXene powder, immerse 2 g of DMSO in MXene powder, add MXene to DMSO and stir magnetically for 30 min, ultrasonically disperse the mixed solution for 10 min, and centrifuge (3000 r / min) for 20 min to remove impurities. Repeat the above stirring, ultrasonic dispersion, centrifugation, and impurity removal steps three times. The ultrasonic power is respectively 100W, 90W, and 80W to completely disperse MXene in DMSO. Weigh 2.5g of solvent-based ink that does not contain high-valent metal ions and add it to the dispersion , after 2 hours of magnetic stirring and ultrasonic dispersion for 20 minutes, the MXene / ink was dried in a vacuum oven at 60°C for 1 hour. The mass ratio of MXene and ink is 1:25.

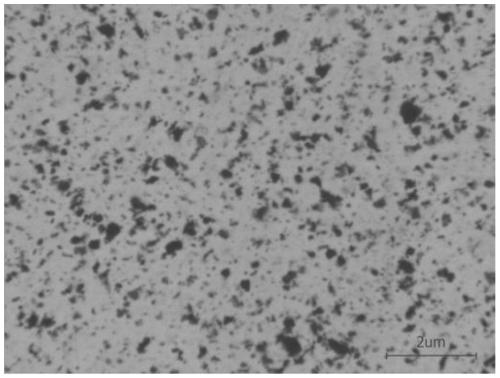

[0066]Put the prepared MXene / ink composite material into the syringe, and then put the cured composite material plate on the printer plate, and the printer will print the MXene / ink onto the composite material plate at a speed of no more than 4mm / sec, with a siz...

Embodiment 2

[0068] Change the quality of the ink to 7.5g, the mass ratio of MXene and the ink is 1:75, and the others are the same as in Example 1.

Embodiment 3

[0070] Change the quality of the ink to 0.5g, the mass ratio of MXene and the ink is 1:5, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com