Flexible gradient surface treatment method of post insulator for extra-high voltage direct current GIL

A post insulator and UHV DC technology, which is applied in the field of preparation of modified insulating polymer materials, can solve problems such as manufacturing process defects, insulator electrical resistance reduction, flashover accidents along the surface, etc., so as to improve operation stability and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) Polish the surface of the insulator with sandpaper to remove impurities attached to the surface;

[0040] 2) Dissolve the PVA powder in deionized water, and disperse the CCTO (copper barium titanate) powder in absolute ethanol, and mix the two solutions uniformly at a certain ratio, stir with a motor at 90°C for 1 hour, and ultrasonically Shake for 2 hours to mix thoroughly, and degas in a vacuum oven for 40 minutes to obtain a PVA / CCTO mixed solution;

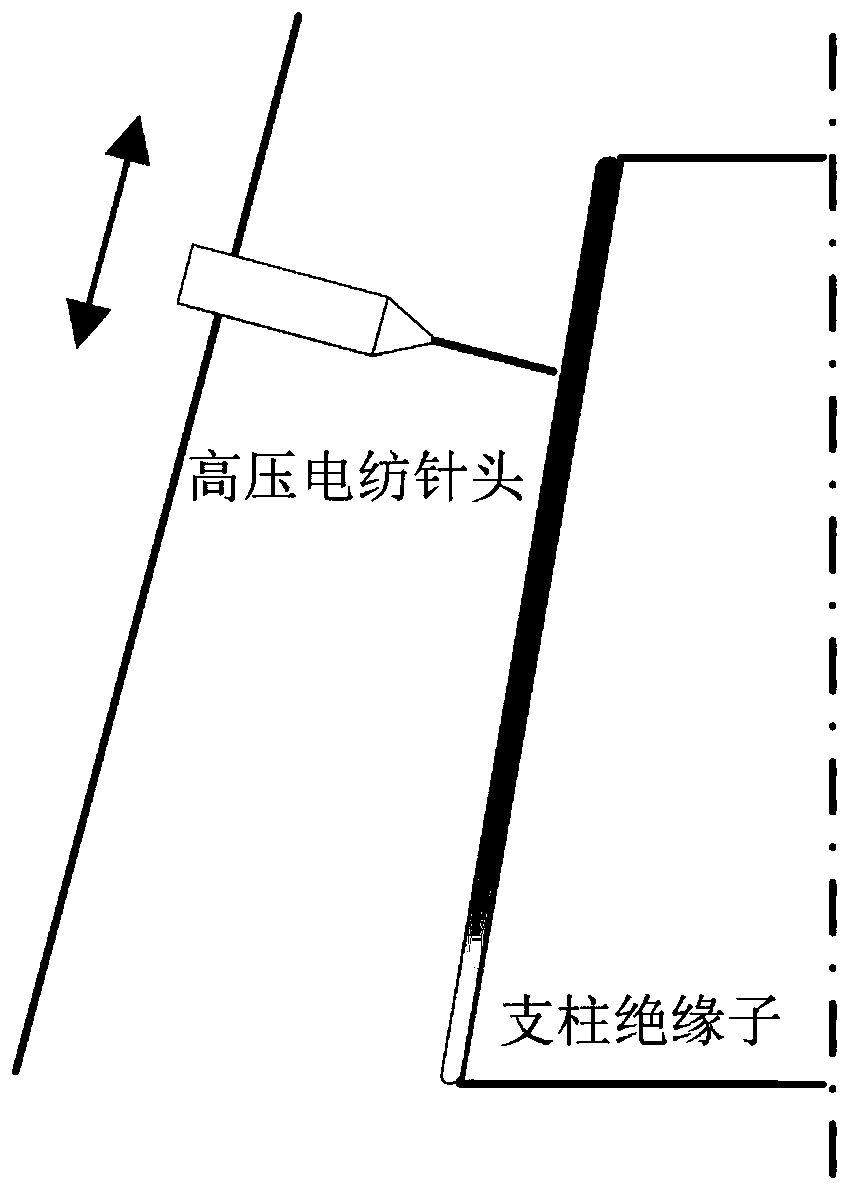

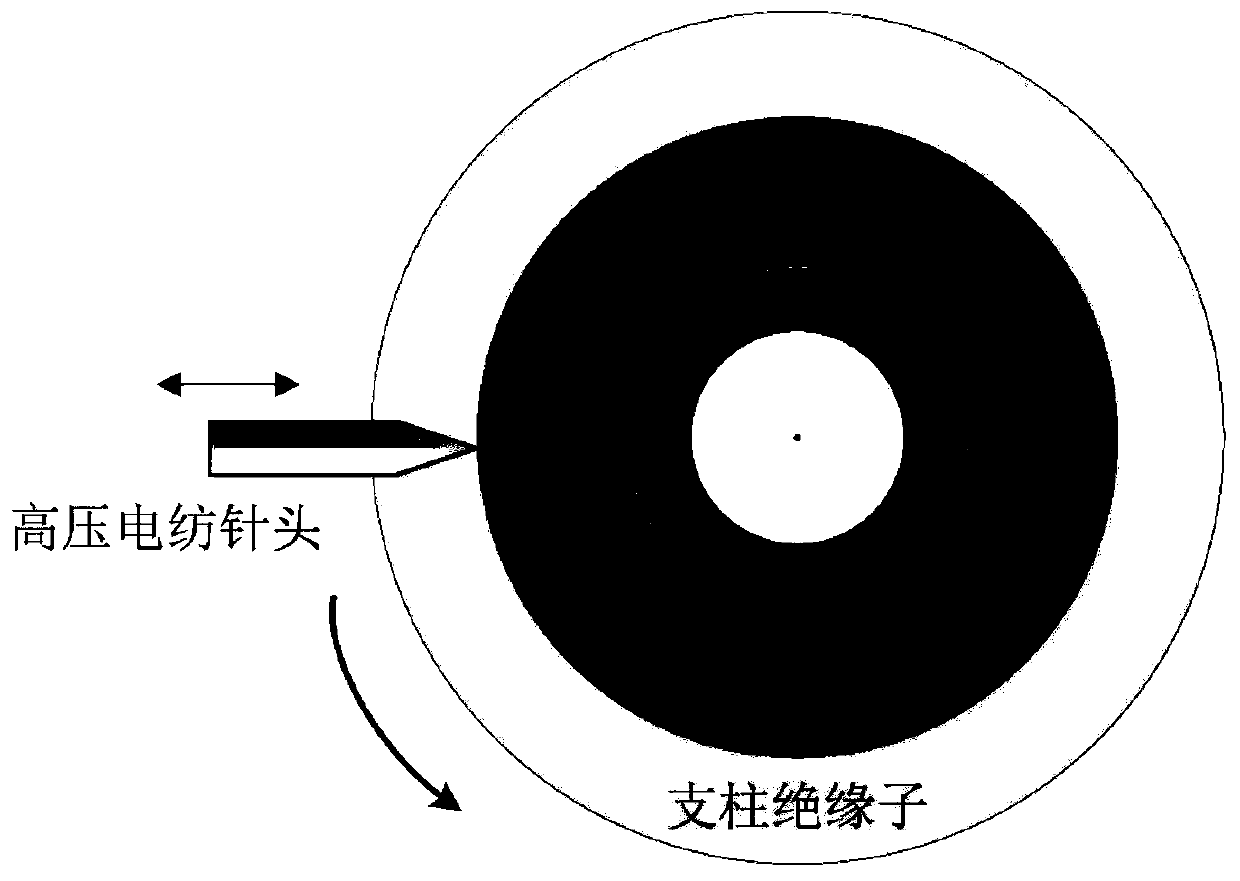

[0041] 3) Place the epoxy resin post insulator in the electrospinning equipment, and the needle port is perpendicular to the surface of the insulator; connect the power supply of the electrode needle at the needle port to charge the electrode needle; turn on the syringe propeller switch, and the paint is drawn from the needle port Spray to the surface of the insulator in a filamentary form; according to the gradient distribution of the insulator, the surface is divided into 4 adjacent rings from the center to the out...

Embodiment 2

[0043] 1) Polish the surface of the insulator with sandpaper to remove impurities attached to the surface;

[0044] 2) Dissolve the PVA powder in deionized water, and disperse the CCTO (copper barium titanate) powder in absolute ethanol, and mix the two solutions uniformly at a certain ratio, stir with a motor at 90°C for 1 hour, and ultrasonically Shake for 2 hours to mix thoroughly, and degas in a vacuum oven for 40 minutes to obtain a PVA / CCTO mixed solution;

[0045]3) Place the epoxy resin post insulator in the electrospinning equipment, and the needle port is perpendicular to the surface of the insulator; connect the power supply of the electrode needle at the needle port to charge the electrode needle; turn on the syringe propeller switch, and the paint is drawn from the needle port Spray to the surface of the insulator in a filamentary form; according to the gradient distribution of the insulator, the surface is divided into 4 adjacent rings from the center to the outs...

Embodiment 3

[0047] 1) Polish the surface of the insulator with sandpaper to remove impurities attached to the surface;

[0048] 2) Dissolve the PVA powder in deionized water, and disperse the CCTO (copper barium titanate) powder in absolute ethanol, and mix the two solutions uniformly at a certain ratio, stir with a motor at 90°C for 1 hour, and ultrasonically Shake for 2 hours to mix thoroughly, and degas in a vacuum oven for 40 minutes to obtain a PVA / CCTO mixed solution;

[0049] 3) Place the epoxy resin post insulator in the electrospinning equipment, and the needle port is perpendicular to the surface of the insulator; connect the power supply of the electrode needle at the needle port to charge the electrode needle; turn on the syringe propeller switch, and the paint is drawn from the needle port Spray to the surface of the insulator in a filamentary form; according to the gradient distribution of the insulator, the surface is divided into 4 adjacent rings from the center to the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com