Femtosecond fiber laser and working method thereof

A femtosecond fiber and laser technology, applied in the field of medical devices, can solve the problems of fiber core mode field matching, power amplification stage laser spontaneous oscillation, and limiting fiber output power, which are not easy to inject signals, so as to ensure the simplicity of the structure and the circuit. Safety, suppression of nonlinear effects, cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

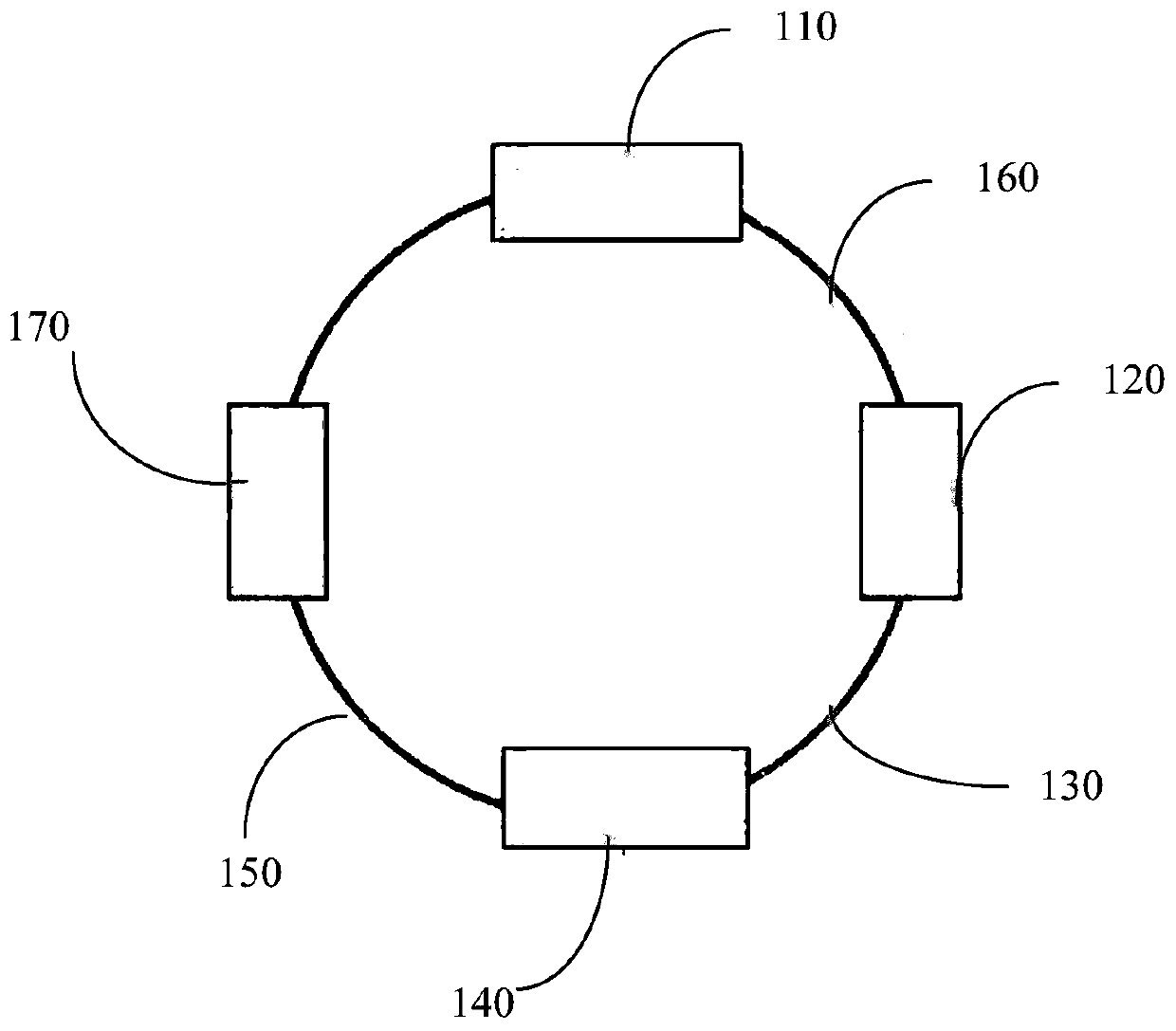

[0029] see figure 1 , is a schematic structural diagram of a femtosecond fiber laser provided by the present invention, including: a self-mode-locked fiber oscillator 110, a pump module 120, a first active fiber 130, a first Bragg grating 140, and a second active fiber 150 , a polarization maintaining fiber 160 and an amplifier 170, the cladding of the second active fiber 150 is engraved with a second Bragg grating.

[0030] Specifically, the polarization maintaining fiber 160 is placed between the self-mode-locked fiber oscillator 110 and the pump module 120, and the first active fiber 130 is placed between the first Bragg grating 140 and the Between the second active optical fiber 150, the self-mode-locked optical fiber oscillator 110, the polarization maintaining optical fiber 160, the pump module 120, the first active optical fiber 130, the first Bragg grating 150, the second active optical fiber 160 and the amplifier 170 are sequentially Seamless fusion forms an all-fibe...

Embodiment 2

[0048] The present invention also provides a working method of a femtosecond fiber laser described in Embodiment 1, comprising the steps of:

[0049] Step S110: the self-mode-locked fiber oscillator 110 generates and outputs the first femtosecond pulsed laser beam;

[0050] Step S120: the first femtosecond pulsed laser beam enters the pump module 120 through the polarization maintaining fiber 160 to form pump light;

[0051] Step S130: the pump light enters the first active optical fiber 130 and oscillates in the resonator formed by the first Bragg grating 140 and the second Bragg grating to form a second femtosecond pulsed laser beam;

[0052] Step S140: the second femtosecond pulsed laser beam is transmitted to the amplifier 170 through the second Bragg grating for power amplification to form a third femtosecond pulsed laser beam;

[0053] Step S150: The third femtosecond pulsed laser beam is output to the self-mode-locked fiber oscillator 110, and the self-mode-locked fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap