Ship cleaning robot and cleaning method

A technology for cleaning robots and ships, applied in ship cleaning devices, ship hulls, ship construction, etc., can solve the problems of single propulsion method, increase resistance, reduce robot stability, etc., to improve cleaning efficiency, reduce forward resistance, and achieve no The effect of repeating a full coverage job

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

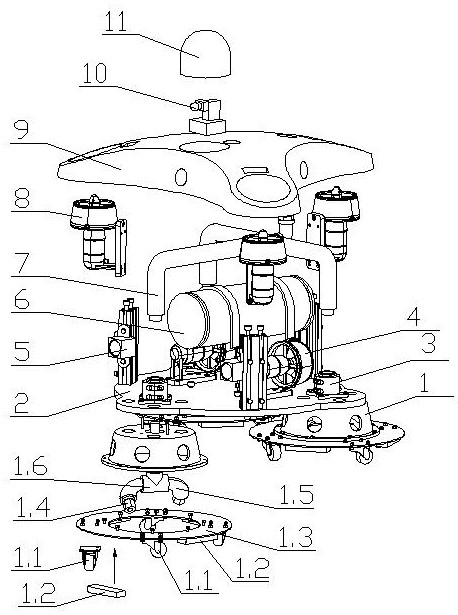

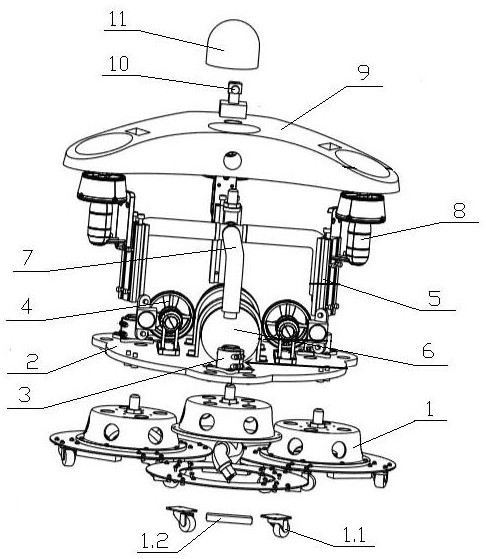

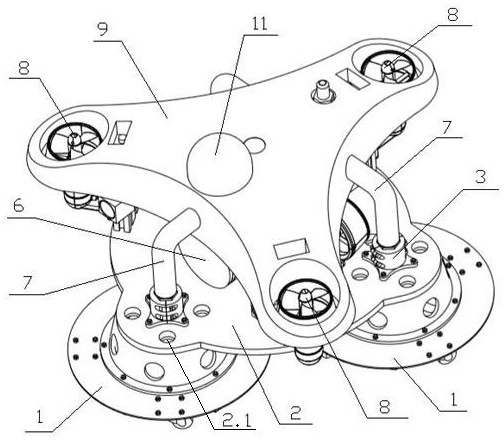

[0046] see Figure 1-Figure 5 , a specific embodiment of the cleaning method of the above-mentioned ship cleaning robot of the present invention, the cleaning method includes the following steps:

[0047] P1: Main program: The controller powers on the cavitation jet nozzles 1.4 in the three rotary cleaning discs, and initializes the electrical components to make them work; the composite adsorption of the vertical pusher 8 and the permanent magnet 1.2 ensures the cleaning of the ship The robot is adsorbed on the surface of the hull, and under the propulsion of the horizontal pusher 4, the ship cleaning robot travels along the set path while spraying water, and collects the data of various sensors in the sensor assembly, and starts the corresponding interruption when the data deviates from the normal value Program: P2: The controller collects the attitude data fed back by the attitude sensor, and when the ship cleaning robot deviates from the predetermined direction of travel by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com