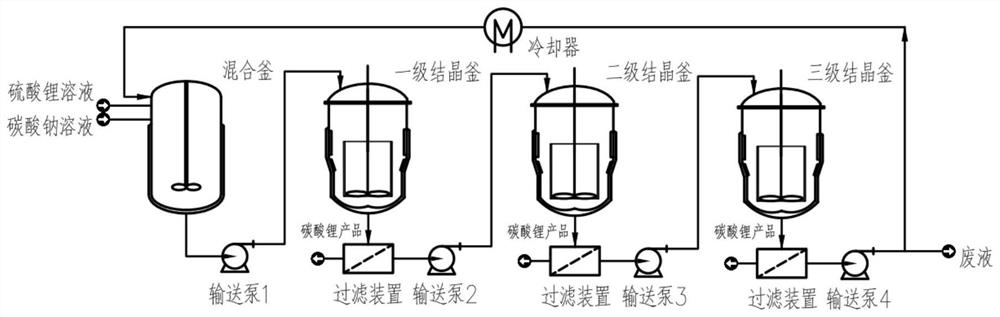

Crystallization method of monodisperse lithium carbonate crystals and method for improving product yield by adopting multistage gradient crystallization

A gradient crystallization and lithium carbonate technology, applied in the direction of lithium carbonate;/acid carbonate, etc., to achieve the effect of complete shape, uniform distribution, and avoiding product agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] In the present embodiment, a crystallization method of monodisperse lithium carbonate crystals is provided, comprising the following steps: using a one-step reaction crystallization method of equimolar and equal volumes of lithium sulfate and sodium carbonate solution, directly adding 40 mL of 9.07 mL of crystallization to a 100 mL crystallization kettle %wt lithium sulfate solution and 40mL sodium carbonate solution with a concentration of 8.74%wt, the temperature is controlled at 65°C, and the laser method is used to control the rapid sampling at the moment of crystallization, that is, a beam of laser light is transmitted through the solution through a laser transmitter. When the laser intensity When the signal dropped suddenly, the slurry was taken out for solid-liquid separation, and the obtained solid was air-dried at 50°C for 10 hours to obtain monodisperse lithium carbonate crystals.

Embodiment 2

[0058] In the present embodiment, a crystallization method of monodisperse lithium carbonate crystals is provided, comprising the following steps: using a one-step reaction crystallization method of equimolar and equal volumes of lithium sulfate and sodium carbonate solution, directly adding 40 mL of crystallization pot with a concentration of 8.44 %wt lithium sulfate solution and 40mL sodium carbonate solution with a concentration of 8.13%wt, the temperature is controlled at 80°C, and the laser method is used to control the rapid sampling at the moment of crystallization, that is, a beam of laser light is transmitted through the solution through a laser transmitter. When the laser intensity When the signal dropped suddenly, the slurry was taken out for solid-liquid separation, and the obtained solid was air-dried at 50°C for 10 hours to obtain monodisperse lithium carbonate crystals.

Embodiment 3

[0060] In the present embodiment, a method for crystallization of monodisperse lithium carbonate crystals is provided, comprising the following steps: using a one-step reaction crystallization method of equimolar and equal volumes of lithium sulfate and sodium carbonate solutions, directly adding 40 mL of 7.87 mL of the crystallization pot to a 100 mL crystallization kettle. %wt lithium sulfate solution and 40mL sodium carbonate solution with a concentration of 7.58%wt, the temperature is controlled at 95°C, and the laser method is used to control the rapid sampling at the moment of crystallization, that is, a beam of laser light is transmitted through the solution through a laser transmitter. When the laser intensity When the signal dropped suddenly, the slurry was taken out for solid-liquid separation, and the obtained solid was air-dried at 50°C for 10 hours to obtain monodisperse lithium carbonate crystals.

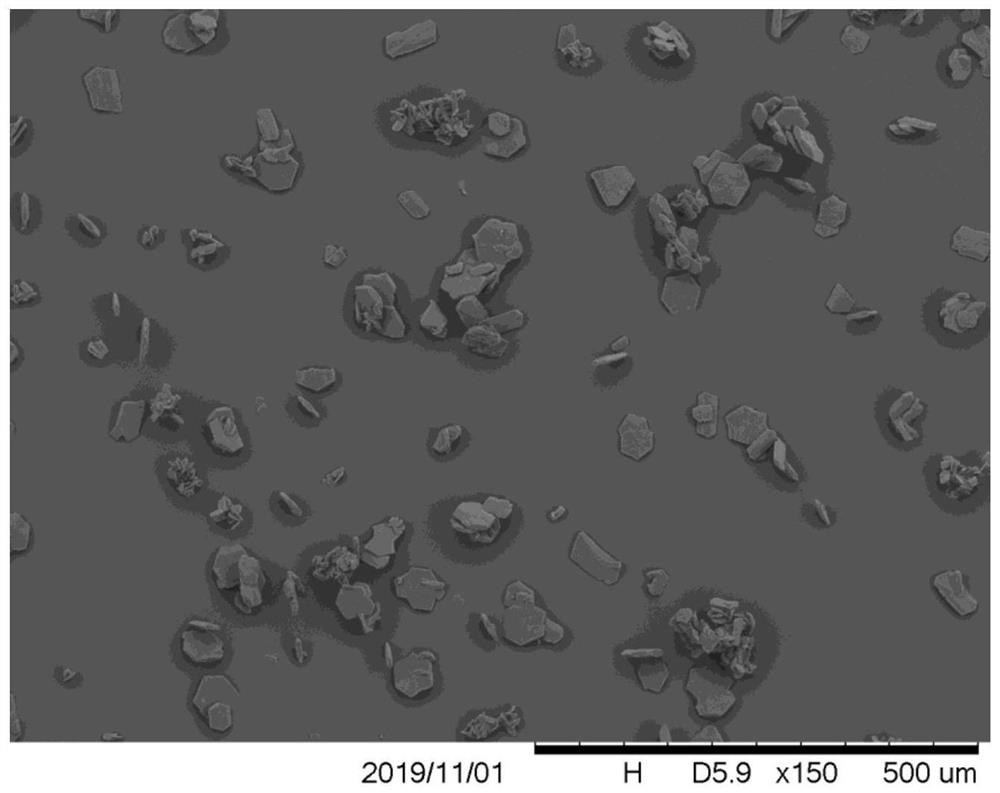

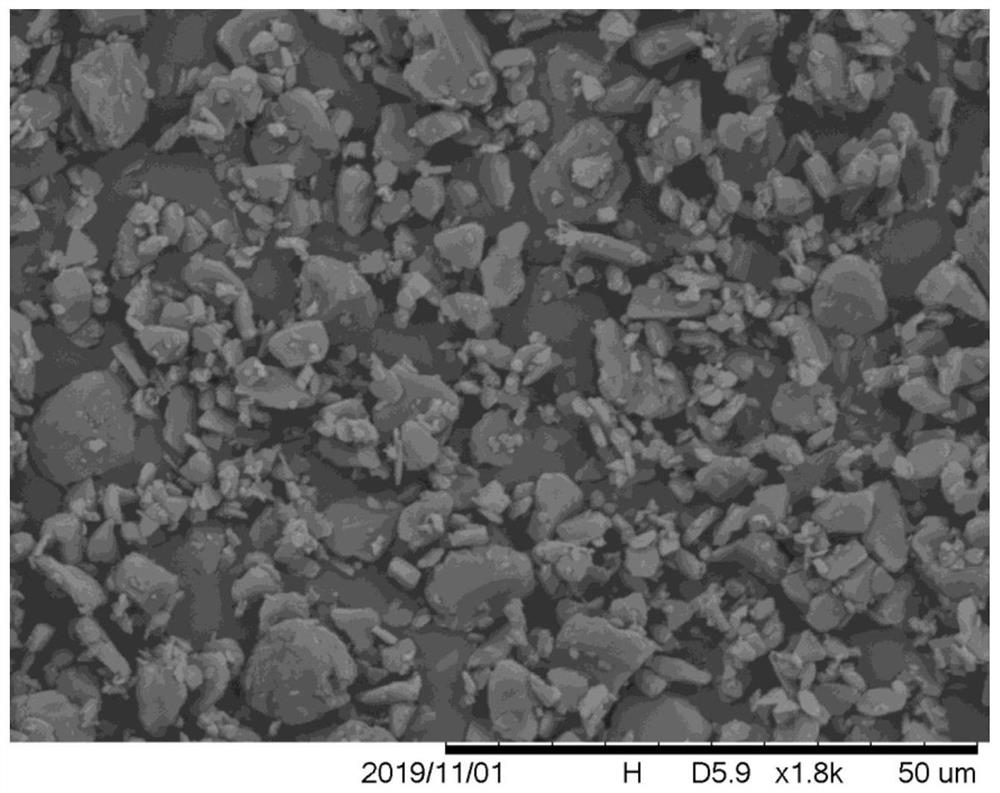

[0061] figure 1 The scanning electron micrograph of the monodisp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com