Methanol and light hydrocarbon coupling cracking device and method

A cracking device and technology for light hydrocarbons, applied in chemical instruments and methods, molecular cracking to produce hydrocarbons, bulk chemical production, etc., can solve the problems of low yield of low-carbon olefins and high reaction energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

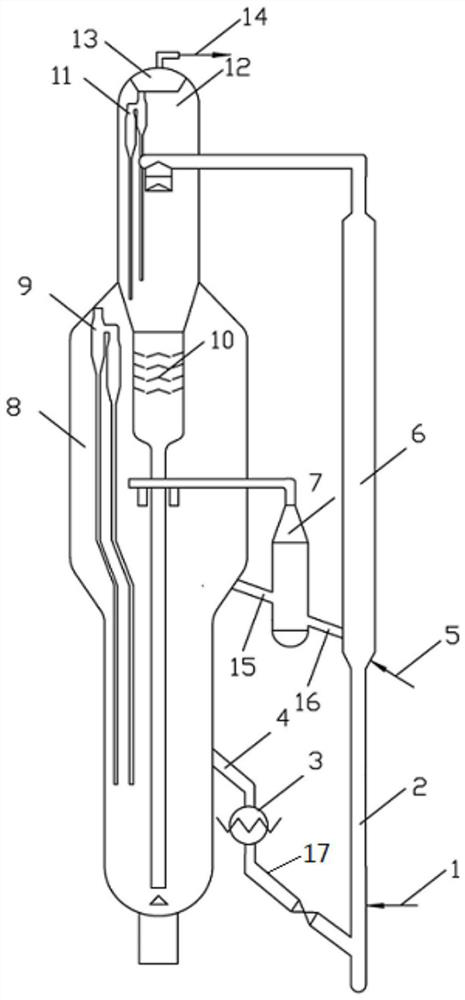

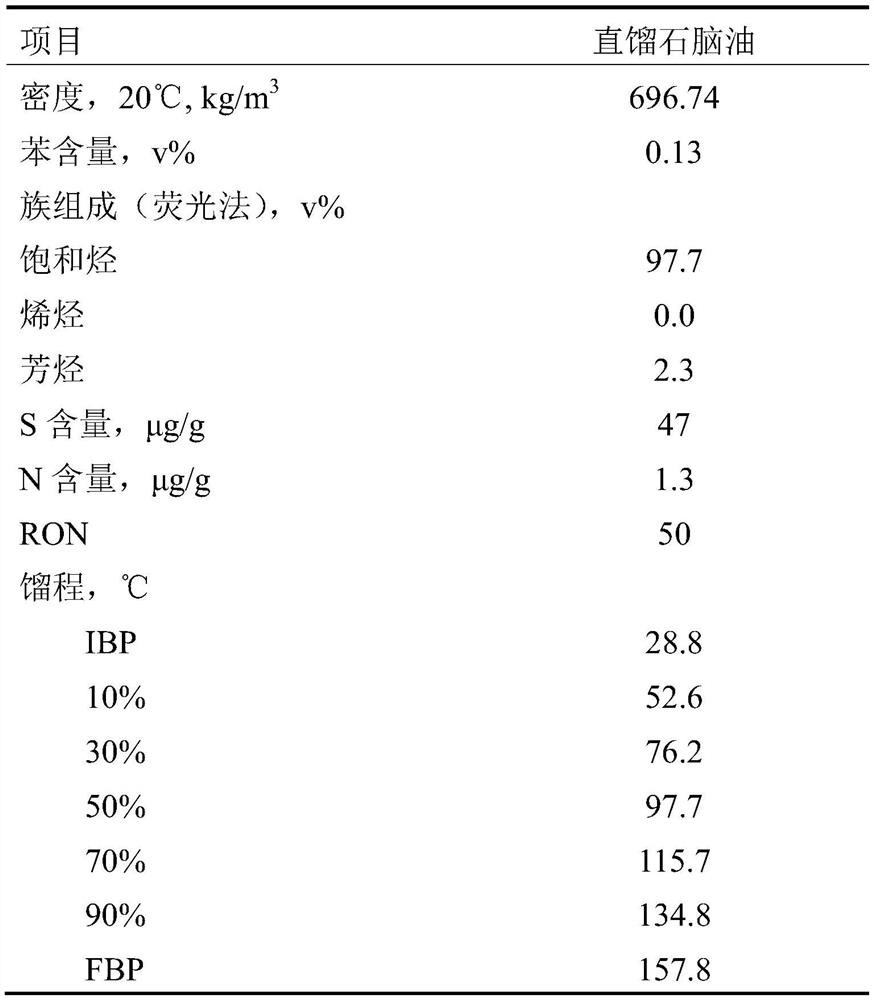

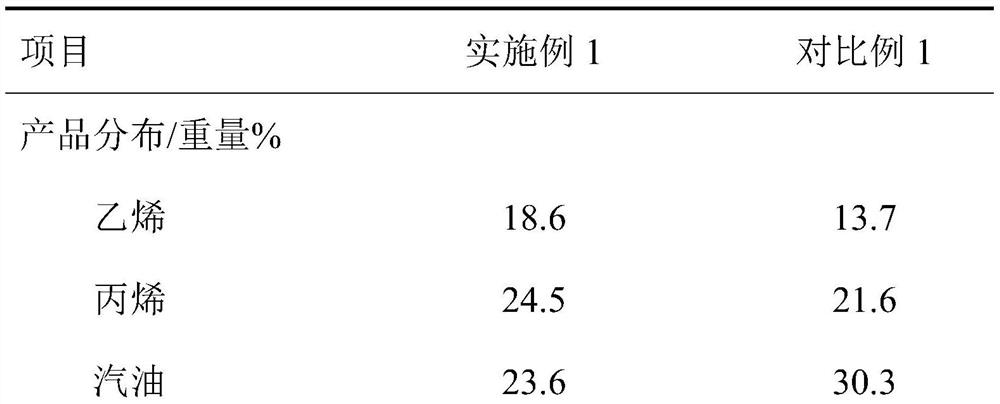

[0076] in such as figure 1 In the methanol-light hydrocarbon coupled cracking unit shown, the light hydrocarbon feed is straight-run naphtha, and the properties of the straight-run naphtha are shown in Table 1. The mass flow rate of the first catalyst in the first regeneration inclined tube and the mass flow rate of the first catalyst in the second regeneration inclined tube to the mass flow ratio of the straight-run naphtha entering the riser reactor is 30:1, and the regenerant temperature is 700°C, the inlet temperature of the riser reactor is 680°C, the outlet temperature is 630°C, and the reaction pressure is 0.1MPa. The inlet temperature of the fluidized bed reactor is 630°C, the outlet temperature is 600°C, and the reaction pressure is 0.1MPa, the mass flow rate of the second catalyst in the third regeneration inclined tube and the mass flow rate of the second catalyst in the fourth regeneration inclined tube and The mass flow ratio of methanol entering the fluidized be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com