A method for preparing high-purity 1,8-cineole from camphor crude oil

A technology of eucalyptol and crude oil, applied in the direction of organic chemistry, can solve the problems of low product purity, low temperature and high energy consumption, and achieve the effect of short process flow, simple equipment operation and higher energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A kind of method concrete steps of preparing high-purity 1,8-cineole from camphor crude oil are as follows:

[0057] Step 1: Under the condition of pressure of -90kPa, collect the distillate section with a temperature of 75°C to 83°C at the top of the tower, which completely removes components with a boiling point above 200°C, and obtains 1,8-eucalyptus with a content of 82% leaf element.

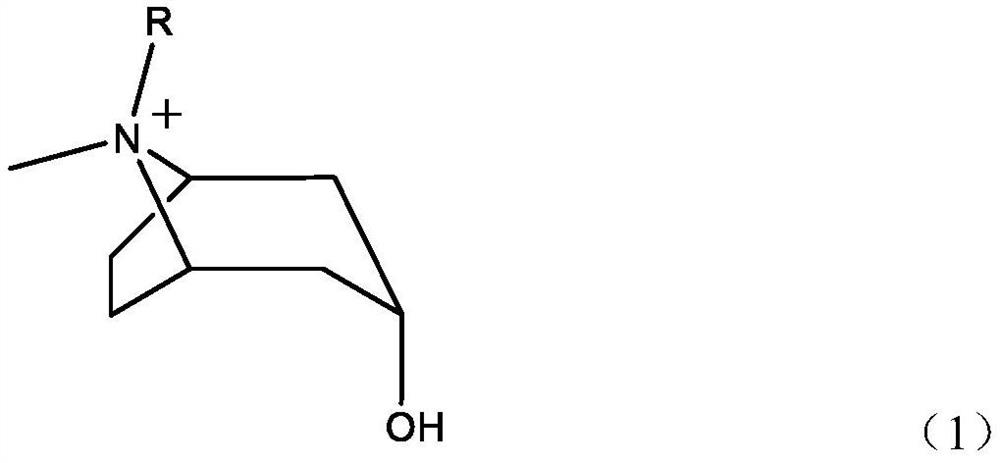

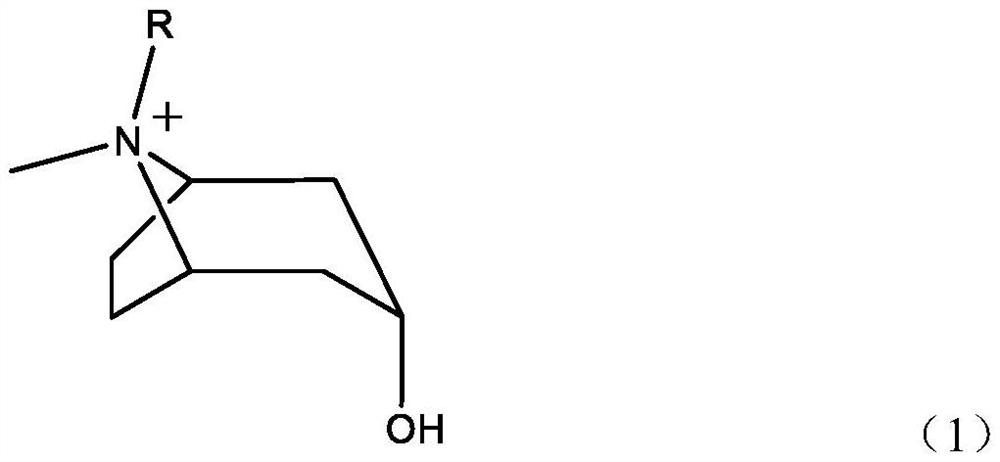

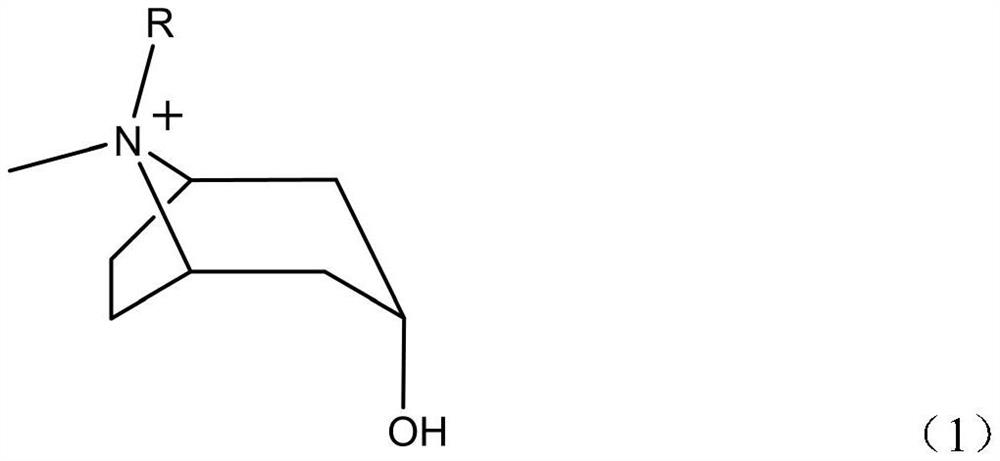

[0058] Step 2: Put C 4 The bromotropine alcohol ionic liquid and ethylene glycol were heated and stirred at 55°C in a molar ratio of 1:5, and mixed uniformly to a transparent liquid, so as to prepare a low eutectic solvent for extraction.

[0059] Step 3: Add 200g of camphor leaf oil containing 82% 1,8-cineole and 200g of the eutectic solvent prepared in step 2 or recovered after extraction and separation into the mixing tank, and stir and mix at 10°C for 0.5h to make it Full exposure to mass transfer. After standing still for 1 hour, the supernatant liquid was released and transf...

Embodiment 2

[0061] A kind of method concrete steps of preparing high-purity 1,8-cineole from camphor crude oil are as follows:

[0062] Step 1: Same as Embodiment 1 (omitted here)

[0063] Step 2: Put C 6 The bromotropine alcohol ionic liquid and ethylene glycol were heated and stirred at 55° C. and mixed uniformly at a molar ratio of 1:10.

[0064] Step 3: Add 200g of camphor leaf oil containing 82% 1,8-cineole and 400g of the low eutectic solvent prepared in step 2 or recovered after extraction and separation into the mixing tank, stir and mix at 25°C for 1 hour to fully contact Mass transfer, after standing for 2 hours, transfer the supernatant to another stirring tank, add 600g of water and stir at 25°C for 1.5 hours, let stand for 1.5 hours, release the upper liquid to obtain 1,8-cineole with a purity of 99% .

Embodiment 3

[0066] A kind of method concrete steps of preparing high-purity 1,8-cineole from camphor crude oil are as follows:

[0067] Step 1: Same as Embodiment 1 (omitted here)

[0068] Step 2: Put C 8 The bromotropine alcohol ionic liquid and ethylene glycol were heated and mixed uniformly at 60°C at a molar ratio of 1:10.

[0069] Step 3: Add 200g of camphor leaf oil containing 82% 1,8-cineole and 600g of the low eutectic solvent prepared in step 2 or recovered after extraction and separation into the mixing tank, and stir and mix at 40°C for 1.5h to fully Contact mass transfer, after standing for 3 hours, transfer the supernatant to another stirring tank, add 720g of water, stir at 40°C for 2 hours, let stand for 2 hours, release the upper liquid to obtain 1,8-cineole with a purity of 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com