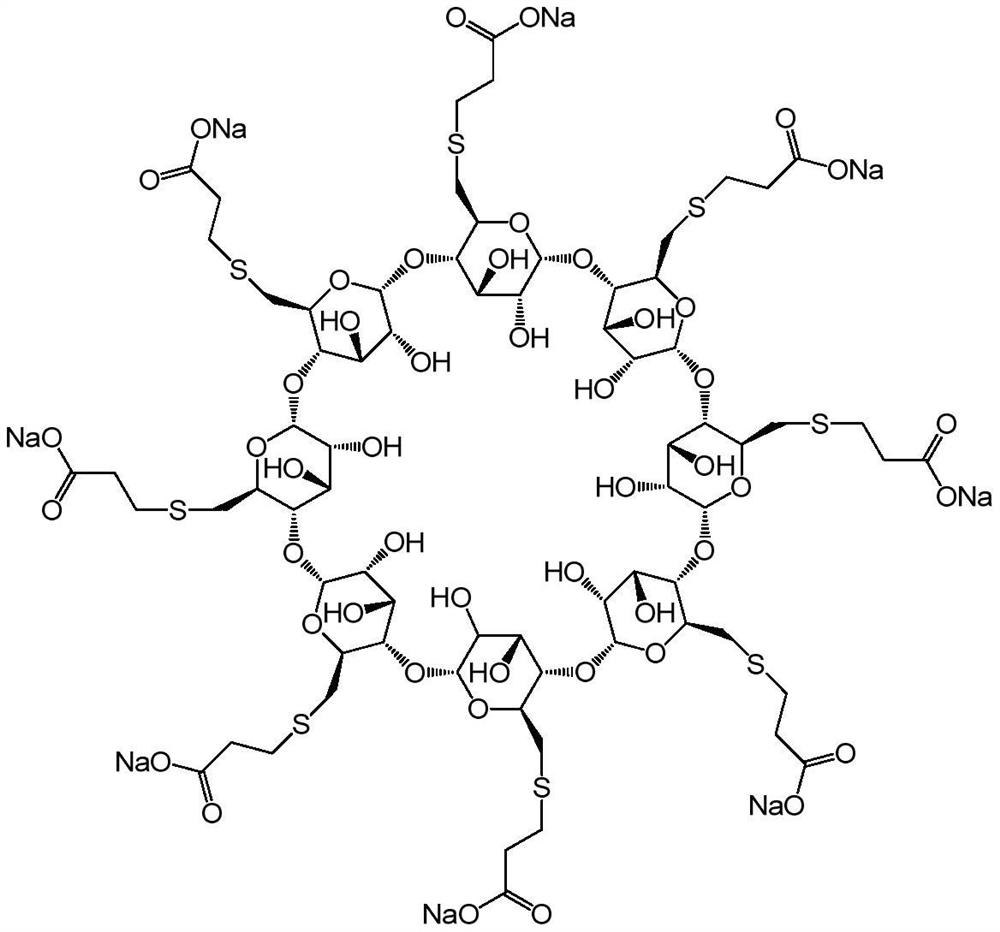

Method for reducing turbidity andremoving visible foreign matters of sugammadex sodium

A sugammadex sodium and turbidity technology, which is applied in the field of sugammadex sodium injection turbidity and visible foreign matter removal, can solve problems such as blocked capillaries, adverse reactions, and threats to the life safety of patients, and achieve efficient removal , Product quality is stable, and the effect of improving quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for removing sugammadex sodium turbidity and visible foreign matter of the present invention, comprising the following steps:

[0032] Dissolve 10g of sugammadex sodium in 100mL of water for injection, adjust the pH to 7.5, heat up to 80°C under the protection of nitrogen and keep stirring for 5 hours at a stirring speed of 80r / min to cause the turbidity of sugammadex sodium by heating Precipitation and precipitation of substances and visible foreign matter, then lower the temperature to 25 ° C, and circulate and filter through a filter membrane with a pore size of 0.10 μm for 5 hours to obtain sugammadex sodium that removes turbidity and visible foreign matter. Pour 5mL of the obtained solution into the ampoule and sterilize at 121°C for 30min. Observation was carried out by a clarity detector, and the result was obtained: the obtained solution was clear and transparent, and the clarity was less than No. 0.5 turbidity standard solution, equivalent to purified ...

Embodiment 2

[0038] A method for removing sugammadex sodium turbidity and visible foreign matter of the present invention, comprising the following steps:

[0039] Dissolve 10g of sugammadex sodium in 90mL of water for injection, set the volume to 100mL, adjust the pH to 7.5, heat up to 80°C under nitrogen protection and keep stirring for 5 hours at a stirring speed of 150r / min, then cool down to 25°C, Circulate and filter through a filter membrane with a pore size of 0.10 μm for 5 hours to remove turbidity substances and visible foreign matter of sugammadex sodium. Pour 5mL of the obtained solution into the ampoule and sterilize at 121°C for 30min. Under the clarification instrument, it is clear and transparent, which is equivalent to purified water, without turbidity and opalescence. After the injection was left to stand at room temperature for 72 hours, the solution was still clear and transparent, comparable to purified water, and no white dot-like visible foreign matter was produced....

Embodiment 3

[0045] A method for removing sugammadex sodium turbidity and visible foreign matter of the present invention, comprising the following steps:

[0046] Dissolve 10g of sugammadex sodium in 100mL of water for injection, heat up to 85°C under nitrogen protection and keep stirring for 3 hours at a stirring speed of 120r / min, cool down to 25°C, and circulate and filter through a filter membrane with a pore size of 0.22μm 3 Hours, remove the turbidity and visible foreign matter of sugammadex sodium. Pour 5mL of the obtained solution into the ampoule and sterilize at 121°C for 30min. It is clear and transparent under the test of the clarification instrument, and the clarity is equivalent to that of purified water. There is no turbidity, opalescence, and no white point-like visible foreign matter.

[0047] The sugammadex sodium used in the present invention can be obtained by existing freeze-drying methods, but is not limited thereto:

[0048] Add 20 g of crude sugammadex sodium int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com