Preparation method of oregano essential oil nano-microcapsules

A technology of nano-microcapsules and essential oils, which is applied in the direction of antimicrobial preservation of food ingredients, food shaping, food preservation, etc. It can solve the problems of inconvenient sterilization, reduce fruit and vegetable rot, simplify the preparation process, and prolong the action time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

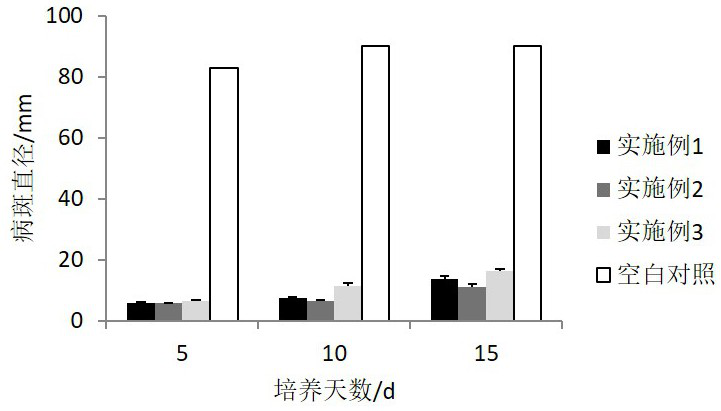

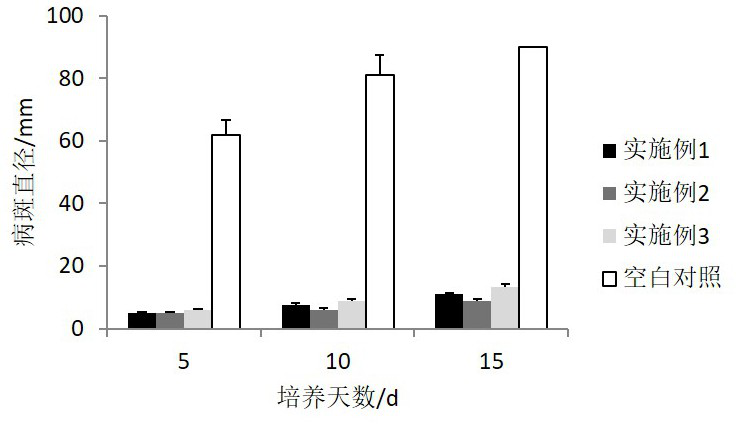

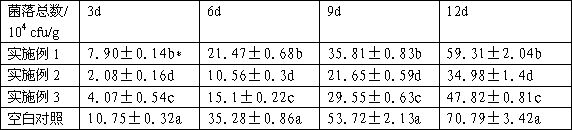

Examples

Embodiment 1

[0025] Take 1g of gelatin and 2g of gum arabic, dissolve them separately, and then mix them evenly to prepare a 300 mL 0.5% mixed solution, then add 1.0 g of oregano essential oil to the mixed solution, disperse at a high speed of 1000 r / min for 3 min, and use 10 % glacial acetic acid to adjust the pH to 4.9, continue to stir at 40 °C for 20 minutes, then take it out, then cool it down to about 10 °C with an ice-water bath, adjust the pH to 6.0 with 10% sodium hydroxide, add 0.3 g of curing agent TGase, and stir Solidify for 3 hours, stand and filter with suction to obtain the wet sac product, then spread the wet sac product on a petri dish, pre-cool at -20°C for 24 hours, and then freeze-dry under 1 Pa pressure vacuum condition, the time is not low In 24 h, solid nanocapsules were obtained.

[0026] The newly prepared nano-microcapsules of oregano essential oil had an average particle size of 132±10 nm, an embedding rate of 85.35, and a Zeta potential of -39.6±0.7 mV.

Embodiment 2

[0028] Take 1 g of gelatin and 1 g of gum arabic, dissolve them separately, and then mix them evenly to prepare 200 mL of 0.5% mixed solution, then add 2 g of oregano essential oil to the mixed solution, disperse at a high speed of 1000 r / min for 3 min, and use 10 % glacial acetic acid to adjust the pH to 4.8, continue to stir at 45 °C for 30 min, then take it out, then use an ice-water bath to cool down to about 10 °C, use 10% sodium hydroxide to adjust the pH to 6.0, add 0.4 g of curing agent TGase, and stir Solidify for 3 hours, stand and filter with suction to obtain the wet sac product, then spread the wet sac product on a petri dish, pre-cool at -20°C for 24 hours, and then freeze-dry under 1 Pa pressure vacuum condition, the time is not low In 24 h, solid nanocapsules were obtained.

[0029] The newly prepared nano-microcapsules of oregano essential oil had an average particle size of 125±11 nm, an embedding rate of 88.3%, and a Zeta potential of -42.5±0.6 mV.

Embodiment 3

[0031] Take 2 g of gelatin and 1 g of gum arabic, dissolve them separately, and then mix them evenly to prepare a 300 mL 0.5% mixed solution, then add 6 g of oregano essential oil to the mixed solution, and disperse at a high speed of 1000 r / min for 3 min. Use 10% glacial acetic acid to adjust the pH to 5.0, continue to stir at 50°C for 40 minutes, take it out, then use an ice-water bath to cool down to about 10°C, use 10% sodium hydroxide to adjust the pH to 6.0, and add 0.4 g of curing agent TGase , stirred and solidified for 3 h, stood still and filtered to obtain the wet sac product, and then spread the wet sac product on a petri dish, pre-cooled at -20 ℃ for 24 h, and then freeze-dried under 1 Pa pressure vacuum condition, time Not less than 24 h, to obtain solid nano-microcapsules.

[0032] The newly prepared nano-microcapsules of oregano essential oil had an average particle size of 129±9 nm, an embedding rate of 86.7%, and a Zeta potential of -38.7±0.7 mV.

[0033] A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com