A preparation method and application of expanded graphite with preferential adsorption properties for aromatic compounds

An expanded graphite, preferential adsorption technology, applied in the preparation of expanded graphite, the preparation of expanded graphite, can solve the problems of light weight and loose adsorption performance, disadvantage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

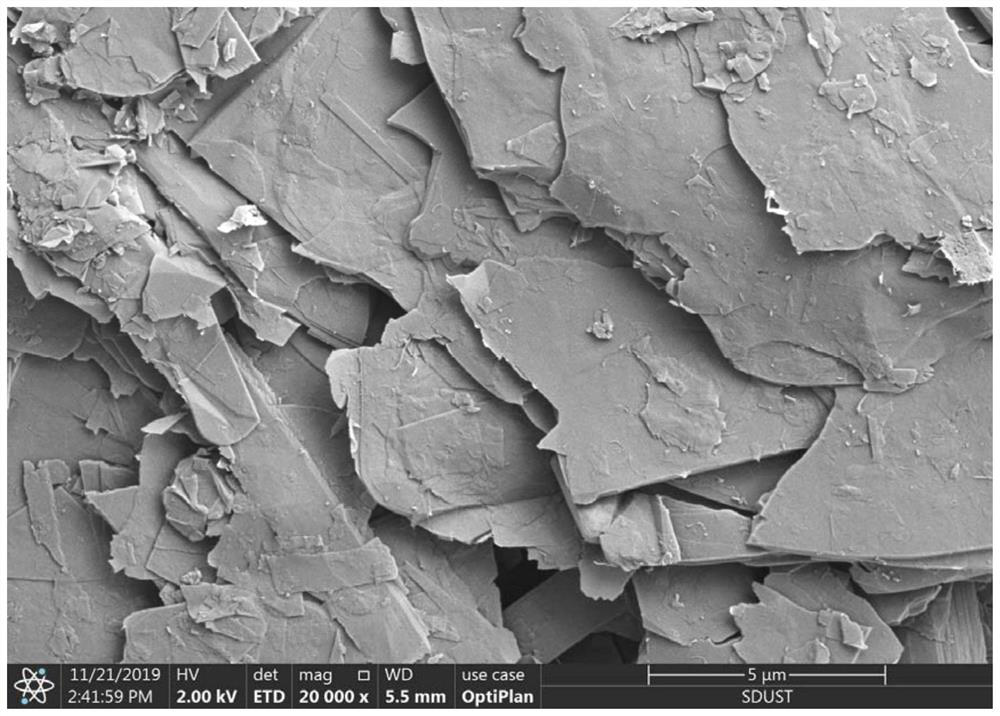

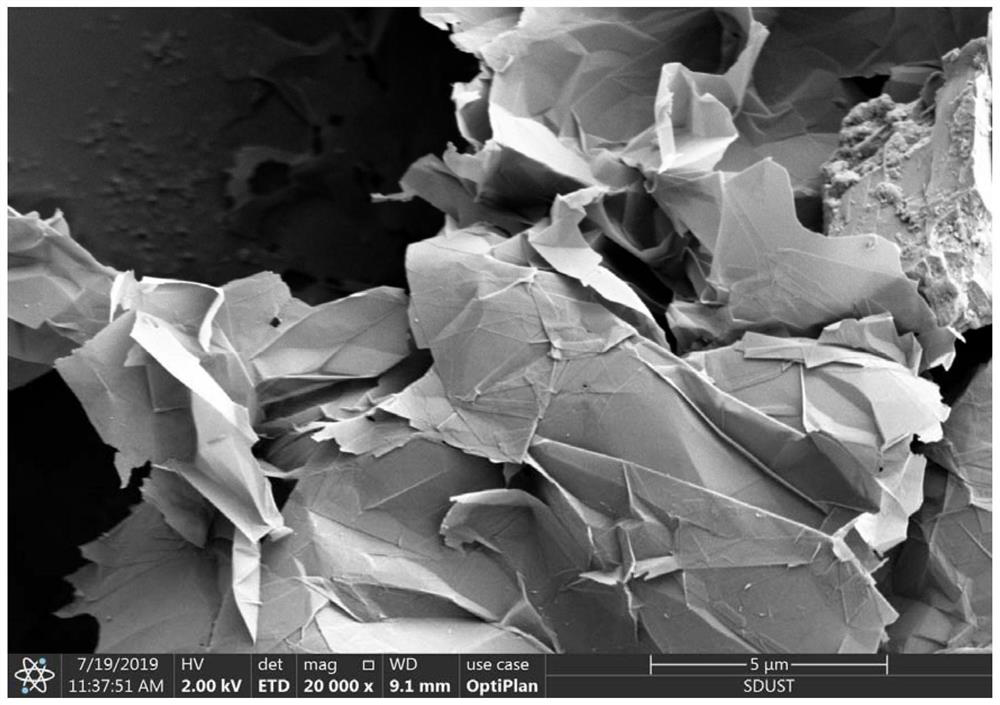

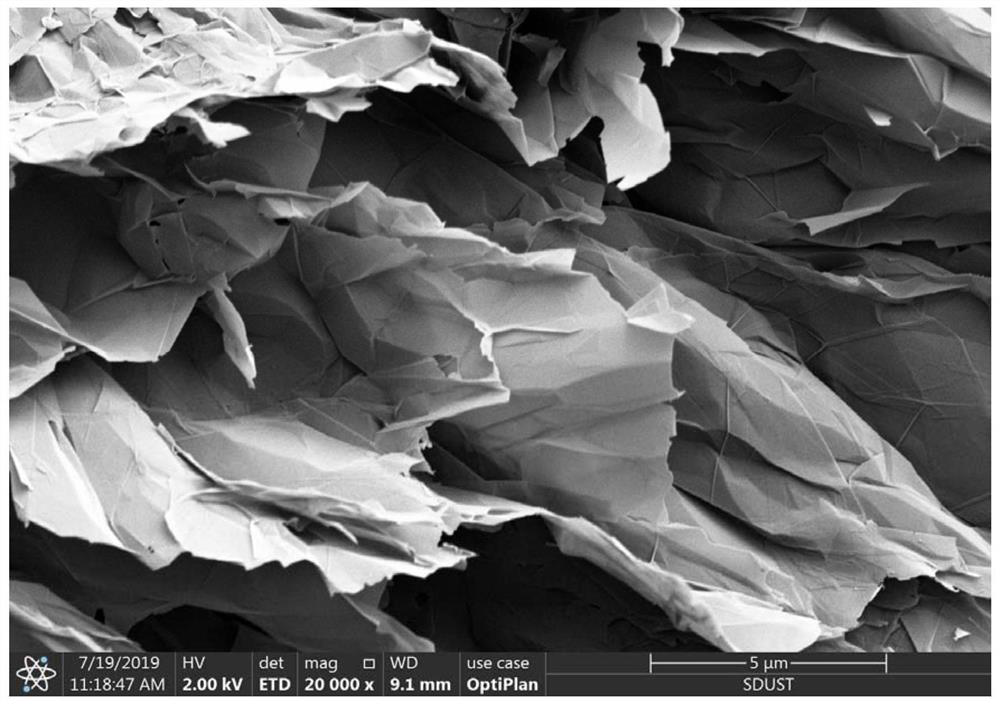

Image

Examples

Embodiment 1

[0035] A preparation method of expanded graphite with preferential adsorption performance for aromatic compounds, comprising the following steps:

[0036] 5 g of natural flake graphite (80 mesh, 99% carbon content, Qingdao Nanshu Hongda Graphite Products Co., Ltd.), add 10 ml of NMP, 12 ml of sulfolane and 15 ml of water, shake and mix, and then add 2 ml of concentrated sulfuric acid and shake and mix. , add 0.5 g of potassium permanganate to dissolve and mix, ultrasonically treat for 5 minutes, and then shake at room temperature for 1 hour;

[0037] Add hydrogen peroxide dropwise with stirring until the brown color and the purple color of the supernatant disappear, and then add 2 ml in excess;

[0038] After filtering and washing until the filtrate is nearly neutral (pH test paper test), the filter paper and the intercalated graphite are transferred to an oven to dry at 105 °C;

[0039] The intercalated graphite was transferred into a beaker and irradiated with a microwave o...

Embodiment 2

[0042] A preparation method of expanded graphite with preferential adsorption performance for aromatic compounds, comprising the following steps:

[0043] 5 grams of natural flake graphite (80 mesh, 99% carbon content, Qingdao Nanshu Hongda Graphite Products Co., Ltd.), add 12 ml of sulfolane and 10 ml of water, shake and mix, add 1 ml of concentrated sulfuric acid, shake and mix, add 0.4 After the potassium permanganate was shaken, dissolved and mixed, ultrasonically treated for 5 minutes, and then shaken at room temperature for 1 hour;

[0044] Add hydrogen peroxide dropwise with stirring until the brown color and the purple color of the supernatant disappear, and then add 2 ml in excess;

[0045] After filtering and washing until the filtrate is nearly neutral (pH test paper test), the filter paper and the intercalated graphite are transferred to an oven to dry at 105 °C;

[0046] The intercalated graphite was transferred into a beaker, and 500 watts of microwave power was...

Embodiment 3

[0049]A preparation method of expanded graphite with preferential adsorption performance for aromatic compounds, comprising the following steps:

[0050] Natural flake graphite (80 mesh, 99% carbon content, Qingdao Nanshu Hongda Graphite Products Co., Ltd.) 5 grams, add 10 ml of NMP and 10 ml of water, shake and mix, add 2 ml of concentrated sulfuric acid, shake and mix, add 0.5 After the potassium permanganate was shaken, dissolved and mixed, ultrasonically treated for 5 minutes, and then shaken at room temperature for 1 hour;

[0051] Add hydrogen peroxide dropwise with stirring until the brown color and the purple color of the supernatant disappear, and then add 2 ml in excess;

[0052] After filtering and washing until the filtrate is nearly neutral (pH test paper test), the filter paper and the intercalated graphite are transferred to an oven to dry at 105 °C;

[0053] The intercalated graphite was transferred into a beaker and irradiated with a microwave of 500 watts fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com