Method for concentrating and softening brine and device thereof

A softening and brine technology, applied in the field of membrane separation, which can solve the problems of low separation coefficient and high energy consumption of nanofiltration membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111] Salt lake brine concentration, softening and separation

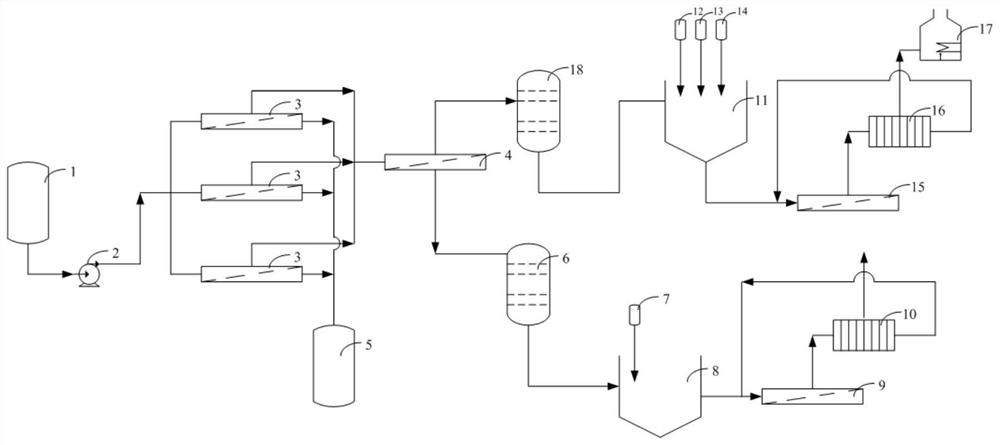

[0112] use figure 1 The device: the salt lake brine in this example is the lithium extraction brine of a certain salt lake in Qinghai. The specific brine content is shown in Table 2. The reverse osmosis membrane group adopts a three-stage type. 99.5%, the rejection rate of magnesium sulfate by the nanofiltration membrane in the nanofiltration membrane group is 98.5%, and two high-pressure pumps are used in series to provide the operating pressure.

[0113] Table 2 Lithium brine content in salt lake

[0114]

[0115]Operating conditions: the operating pressure of the reverse osmosis membrane group is 3.5MPa, the operating pressure of the nanofiltration membrane group is 3.3MPa, the system operating temperature is 28°C, and the pH value is 7.

[0116] Raise the operating pressure of salt lake brine through a high-pressure pump, control the pressure of entering the reverse osmosis membrane at 3.5MPa through th...

Embodiment 2

[0127] Concentration, softening and separation of underground brine

[0128] The underground brine in this example is the underground brine of an enterprise in Shandong, and the specific content is shown in Table 6. The reverse osmosis membrane group adopts a three-stage type, and the rejection rate of sodium chloride by the reverse osmosis membrane in the reverse osmosis membrane group is 99.5%, and the nanofiltration membrane group The rejection rate of magnesium sulfate in the medium nanofiltration membrane is 98.5%, and two high-pressure pumps are used in series to provide the operating pressure.

[0129] Table 6 Underground brine content

[0130]

[0131] Operating conditions: The operating pressure of the reverse osmosis membrane group is 7.5MPa, the operating pressure of the nanofiltration membrane group is 7MPa, the system operating temperature is 28°C, and the pH value is 6.5.

[0132] Raise the operating pressure of salt lake brine through a high-pressure pump, c...

Embodiment 4

[0138] Concentration, softening and separation of brine for salt making

[0139] In this example, the underground brine is the brine of a salt factory in Jiangsu. The specific content is shown in Table 9. The reverse osmosis membrane group adopts a two-stage type. The rejection rate of magnesium sulfate in the medium nanofiltration membrane is 98.5%, and 3 high-pressure pumps are used in series to provide the operating pressure.

[0140] Table 9 Underground brine content

[0141] TDS (g / l) Magnesium (mg / L) Sulfate (mg / L) Calcium (mg / L) Sodium (g / L) salt brine 56 760 1020 420 155

[0142] Operating conditions: the operating pressure of the reverse osmosis membrane group is 11MPa, the operating pressure of the nanofiltration membrane group is 10MPa, the system operating temperature is 28°C, and the pH value is 7.5.

[0143] Raise the operating pressure of salt-making brine through a high-pressure pump, control the pressure of entering the reve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com