Perovskite-like high-temperature thermistor material with different A-site elements and preparation method thereof

A perovskite type, varistor technology, applied in non-adjustable metal resistors, resistors with negative temperature coefficients, resistors, etc., can solve the deterioration of thermal performance, cannot meet high temperature applications above 300 ℃, phase structure instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

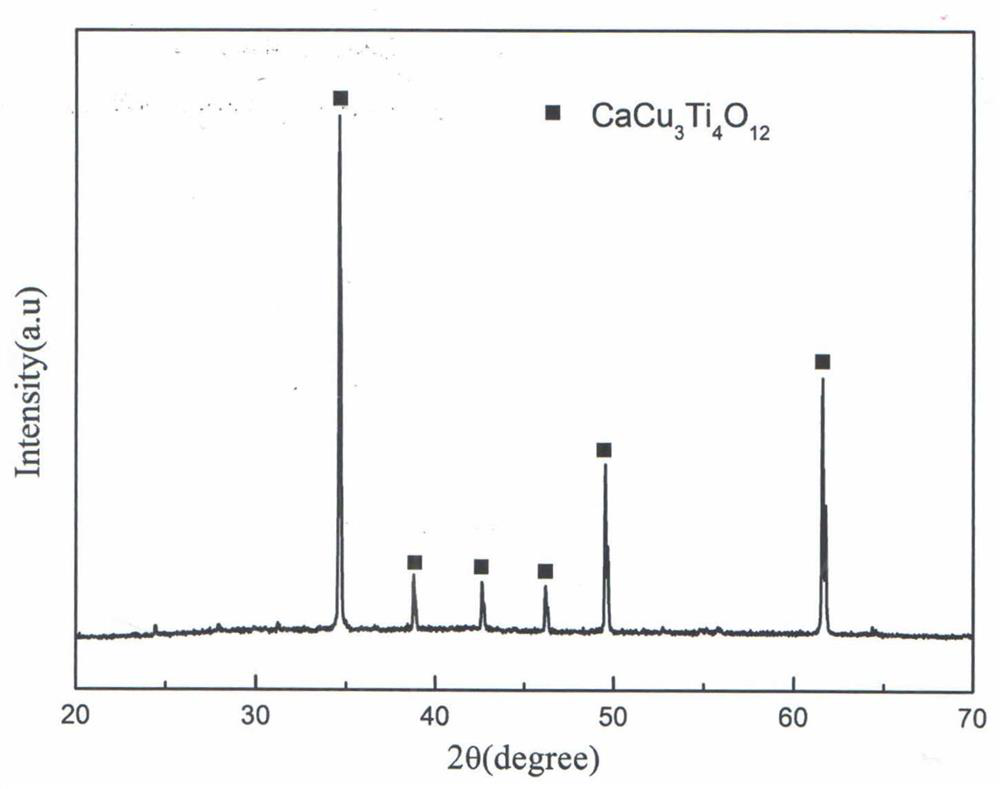

[0016] a. First press CaCu 3 Ti 4 o 12 The composition of the composition, respectively weighed and analyzed pure calcium carbonate, copper oxide and titanium dioxide were mixed, and the mixed raw materials were placed in an agate mortar and ground for 5 hours to obtain a powder;

[0017] b. Calcinate the ground powder in step a at a temperature of 800°C for 4 hours, and grind for 5 hours to obtain CaCu 3 Ti 4 o 12 Powder;

[0018] c, the powder material that step b obtains is with 20Kg / cm 2 The pressure is briquetted for 1 minute, and the formed block material is subjected to cold isostatic pressing, kept at a pressure of 300MPa for 2 minutes, and then sintered at a temperature of 1000°C for 8 hours to obtain a high-temperature heat-sensitive ceramic material ;

[0019] d. Coat the front and back sides of the ceramic material sintered in step c with silver paste electrodes, and then anneal at a temperature of 600°C for 30 minutes to obtain a temperature range of 75°C-6...

Embodiment 2

[0021] a. Press La 2 / 3 Cu 3 Ti 4 o 12 The composition of lanthanum trioxide, copper oxide and titanium dioxide were weighed and mixed respectively, and the mixed raw materials were placed in an agate mortar and ground for 10 hours to obtain a powder;

[0022] b. Calcining the ground powder in step a at a temperature of 900°C for 6 hours, and grinding for 7 hours to obtain La 2 / 3 Cu 3 Ti 4 o 12 Powder;

[0023] c, the powder material that step b obtains is with 15Kg / cm 2 The pressure is briquetted for 0.5 minutes, and the formed block material is subjected to cold isostatic pressing, kept at a pressure of 400MPa for 1 minute, and then sintered at a temperature of 1100°C for 6 hours to obtain a high-temperature heat-sensitive ceramic material ;

[0024] d. Coat the front and back sides of the ceramic material sintered in step c with silver paste electrodes, and then anneal at a temperature of 600°C for 30 minutes to obtain a temperature range of 75°C-600°C and a mater...

Embodiment 3

[0026] a. Press Y 2 / 3 Cu 3 Ti 4 o 12 The composition of yttrium trioxide, copper oxide and titanium dioxide were weighed and mixed respectively, and the mixed raw materials were placed in an agate mortar and ground for 7 hours to obtain a powder;

[0027] b. Calcinate the ground powder in step a at a temperature of 1000°C for 8 hours, and grind for 11 hours to obtain Y 2 / 3 Cu 3 Ti 4 o 12 Powder;

[0028] c, the powder material that step b obtains is with 10Kg / cm 2 The pressure is briquetted for 2 minutes, and the formed block material is subjected to cold isostatic pressing, kept at a pressure of 350MPa for 3 minutes, and then sintered at a temperature of 1200°C for 4 hours to obtain a high-temperature heat-sensitive ceramic material ;

[0029] d. Coat the front and back sides of the ceramic material sintered in step c with silver paste electrodes, and then anneal at a temperature of 600°C for 30 minutes to obtain a temperature range of 75°C-600°C and a material const...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap