Method for producing regenerated sintered porous shale brick by using waste sintered bricks

A technology for discarding sintered bricks and porous bricks, applied in the field of building materials, can solve the problems of high utilization rate of construction waste recycling, less than 5% utilization rate of resource utilization, aggravating environmental impact and pollution, etc., so as to reduce the amount of mining and improve the Density, the effect of improving the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for producing recycled sintered shale porous bricks by utilizing waste sintered bricks, comprising the following steps:

[0043] S1. Raw material pretreatment:

[0044] Recycling, sorting, crushing, grinding and sieving waste fired bricks to obtain waste fired brick powder with particle size ≤ 2mm;

[0045] The shale is crushed, ground and screened to obtain shale powder with a particle size of ≤2mm.

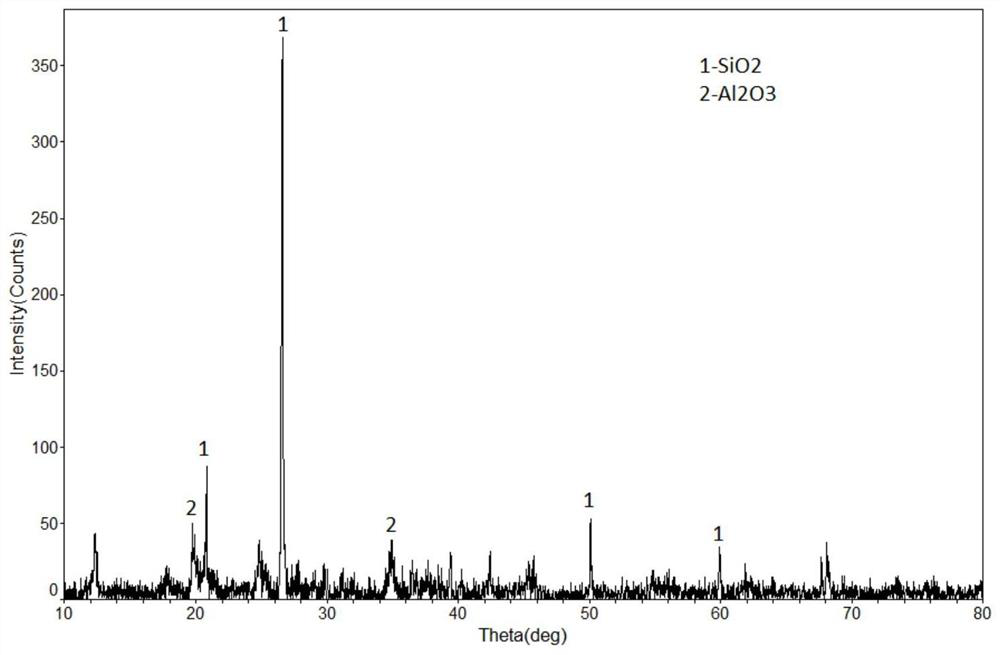

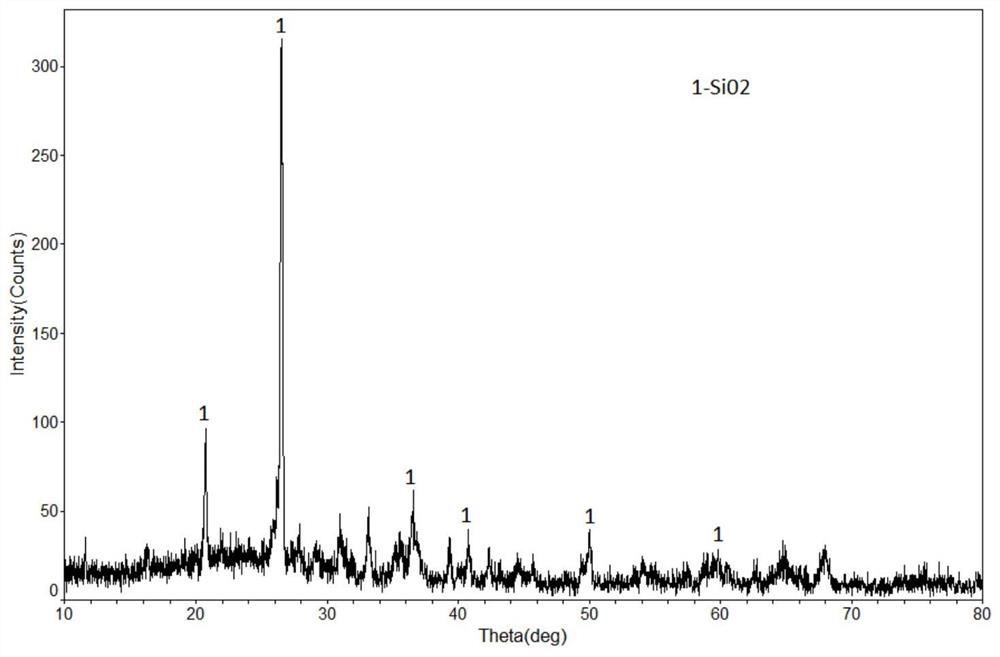

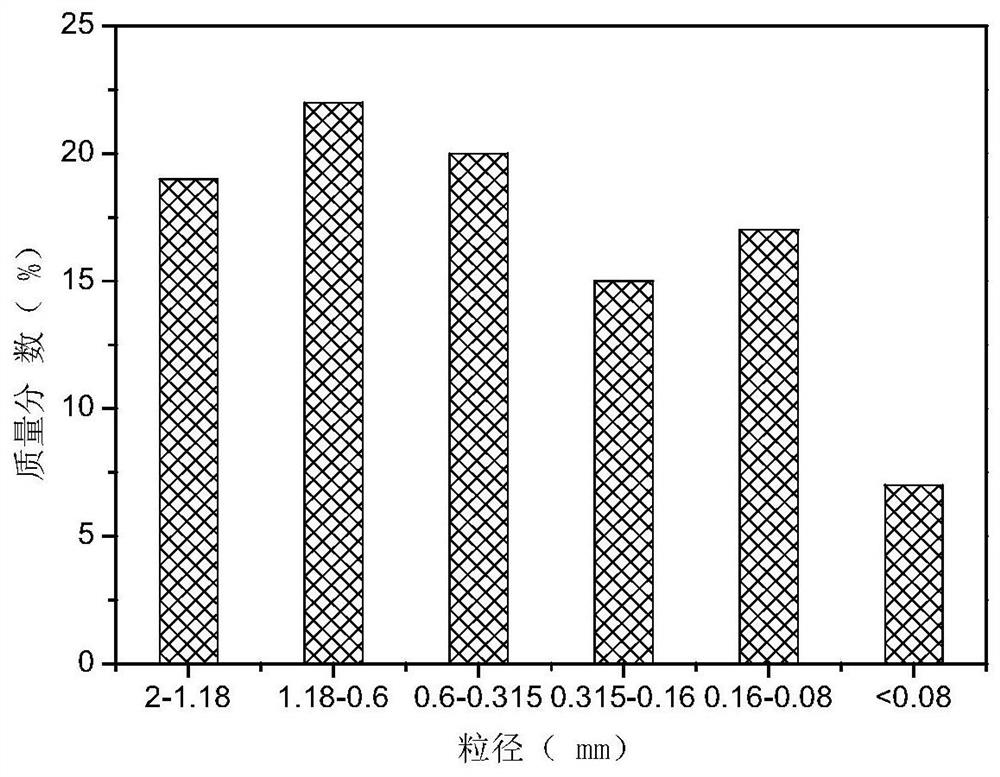

[0046] The particle size distribution of the shale powder and waste fired brick powder is shown in image 3 with Figure 4 .

[0047]S2. Aging:

[0048] The waste fired brick powder and shale powder are mixed to obtain a mixture, and then the mixture is put into an aging warehouse for aging, wherein, in terms of mass fraction, the waste fired brick powder accounts for 30% of the mixture.

[0049] S3. Forming and drying:

[0050] The aged mixture is put into the molded adobe, the adobe is shaped, and then the shaped adobe is dried. Place the formed bricks n...

Embodiment 2

[0053] Example 2 is a method for producing regenerated sintered shale porous bricks by utilizing waste sintered bricks. Compared with Example 1, the calcination temperature is 950° C., and other steps are the same.

Embodiment 3

[0054] Example 3 is a method for producing regenerated sintered shale porous bricks by using waste sintered bricks. Compared with Example 1, the calcination temperature is 1000° C., and other steps are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com