Microstrip film isolator test fixture

A technology of microstrip film and test fixture, which is applied in the direction of instruments, measuring electronics, and measuring devices, can solve the problems of not meeting the requirements of reliability screening and testing of components, low economic efficiency, and low testing efficiency, and achieve improvement The effect of test efficiency and test accuracy, high test accuracy, and wide frequency range of test coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

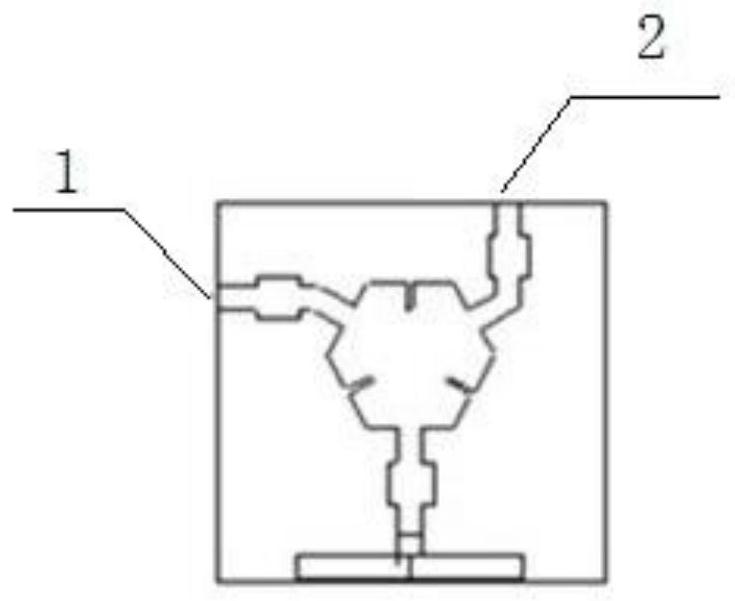

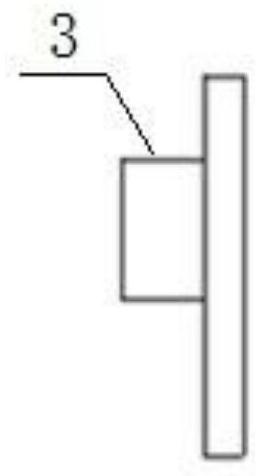

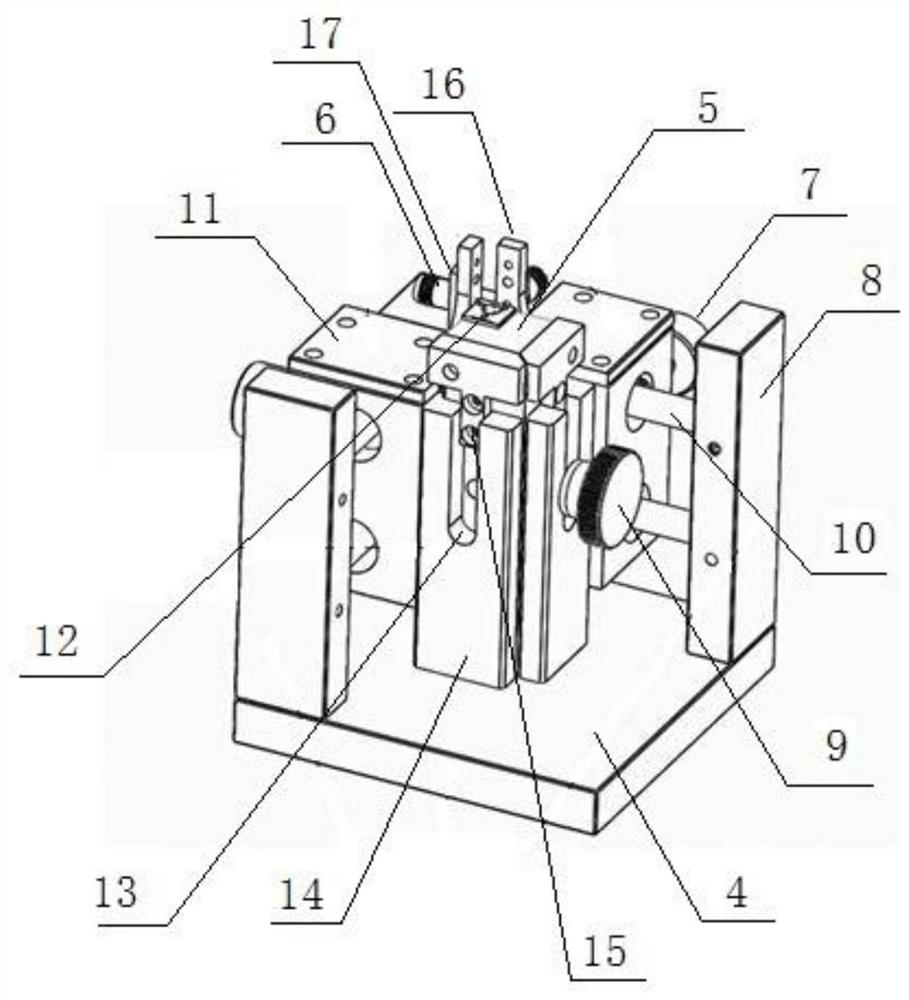

[0024] Embodiment 2, a kind of microstrip film isolator test fixture described in embodiment 1, described elastic support mechanism comprises support frame 14 and compression spring, and compression spring is located at the bottom of stage 5 and is fixed on test platform 4 The support frame 14 is provided with a guide mechanism for the stage 5 to move up and down in the vertical direction. The guide mechanism includes a concave 13 groove on the support frame 14 and a guide block matched with the groove 13, the groove 13 adopts a U-shaped groove, and the guide block is fixed on the object stage 5 to ensure that the object stage moves up and down along the vertical direction during actual use.

Embodiment 3

[0025] Embodiment 3, a kind of microstrip film isolator test fixture described in embodiment 1, is provided with stage locking mechanism on described support frame 14, and stage locking mechanism is arranged in groove 13, so The stage locking mechanism is a stage lock nut 9, and a number of threaded holes 15 that cooperate with the stage lock nut 9 are arranged on the stage, and the threaded holes 15 are vertically arranged to ensure that the actual use process The up and down travel of the middle stage is controllable.

Embodiment 4

[0026] Embodiment 4, a kind of microstrip thin-film isolator test fixture described in embodiment 1, is provided with on described test platform 4 and adjusts the lateral adjustment mechanism of radio frequency connector 6 horizontal positions, and described lateral adjustment mechanism includes horizontal setting The sliding rail 10 and the sliding seat 11 mounted on the sliding rail 10 are provided with the sliding seat locking nut 7 fixing the sliding seat 11 on the sliding rail 10 on the sliding seat 11, and the radio frequency connector 6 is mounted on the sliding seat 11, the adjustment slide rail 10 is two horizontally arranged slide bars, the upper and lower, and the test platform 4 is provided with a column 8, and the slide bar is mounted on the column 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com