Method for predicting stress field in laser cladding manufacturing process of aluminum oxide ceramic matrix composite coating

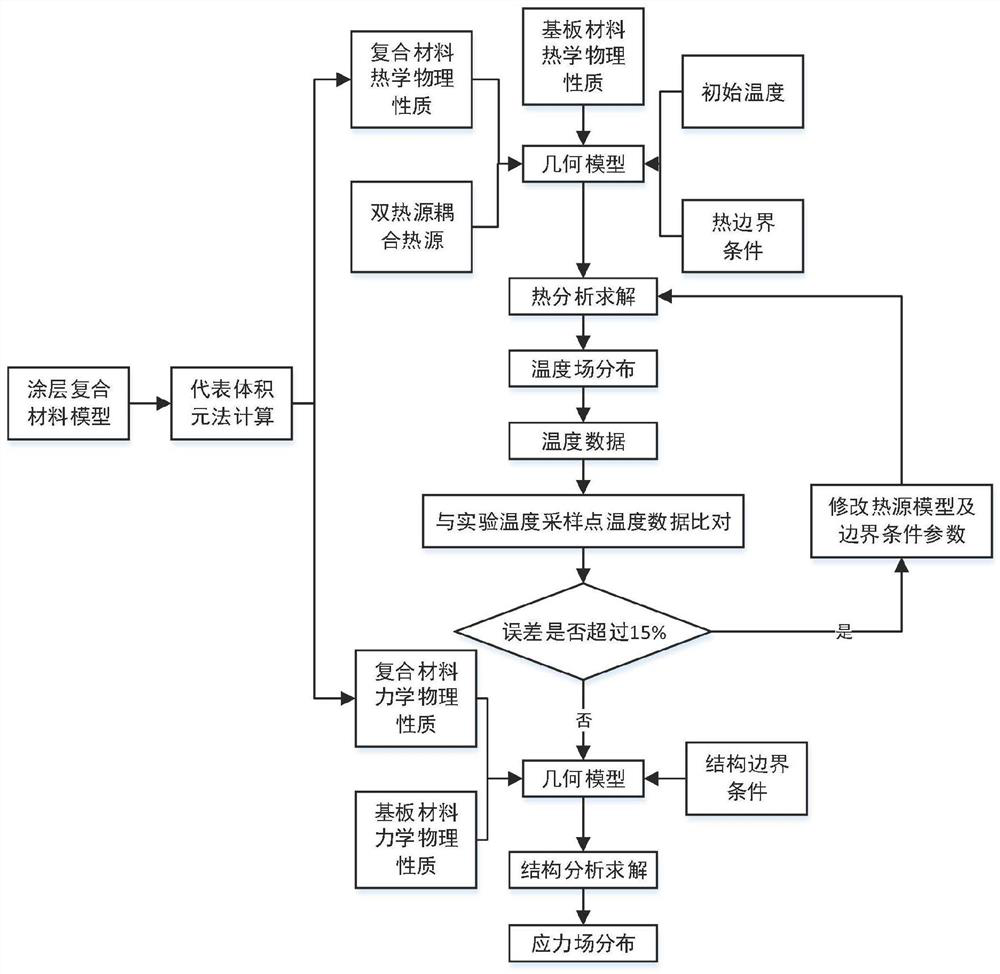

A technology of alumina ceramics and composite materials, applied in chemical process analysis/design, computer materials science, computational theoretical chemistry, etc., can solve problems such as inability to apply composite coatings, poor accuracy, and poor precision, and achieve optimal manufacturing parameters , Guaranteed accuracy, accurate heat source input effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

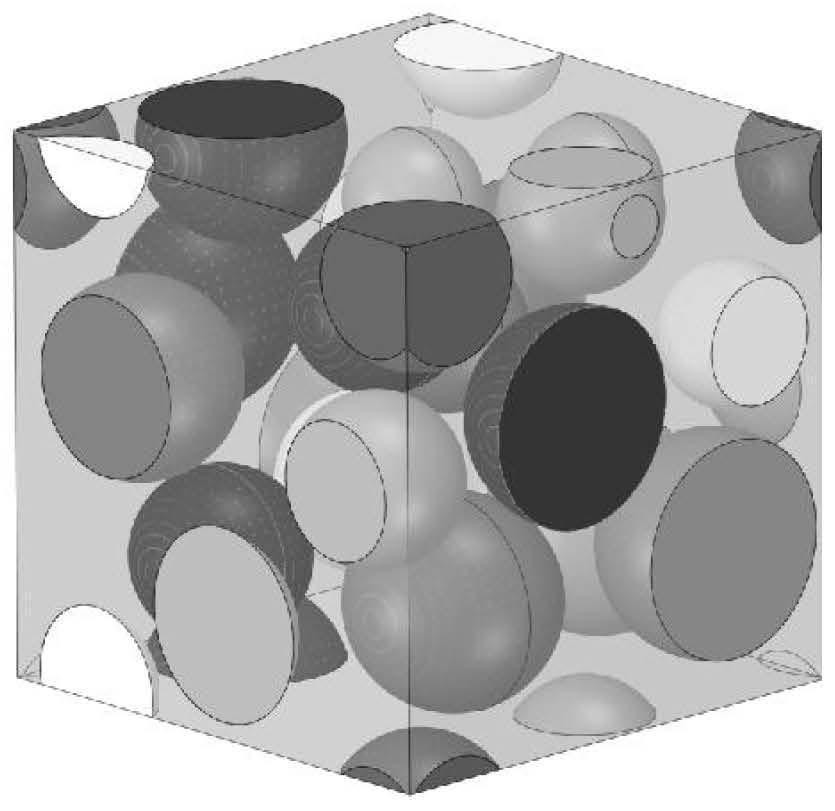

[0072] The composite material model is established, and the properties of the alumina ceramic matrix composite coating are calculated, wherein the alumina ceramic matrix composite coating is formed by laser-induced thermite reaction of aluminum powder and ferric oxide powder, and the aluminum powder and and the particle size of ferric oxide powder are 30-50 μm; the thermal physical parameters of the alumina ceramic matrix composite material coating are as shown in Table 1;

[0073] Table 1 The thermophysical parameters of the alumina ceramic matrix composite coating based on the composite material model

[0074]

[0075] Establish a single-pass cladding geometric model, in which the size of the experimental substrate (specifically titanium alloy substrate) model is 100mm*100mm*5mm, and the size of the single-pass cladding coating is 100mm*3mm*0.5mm, such as Figure 7 shown;

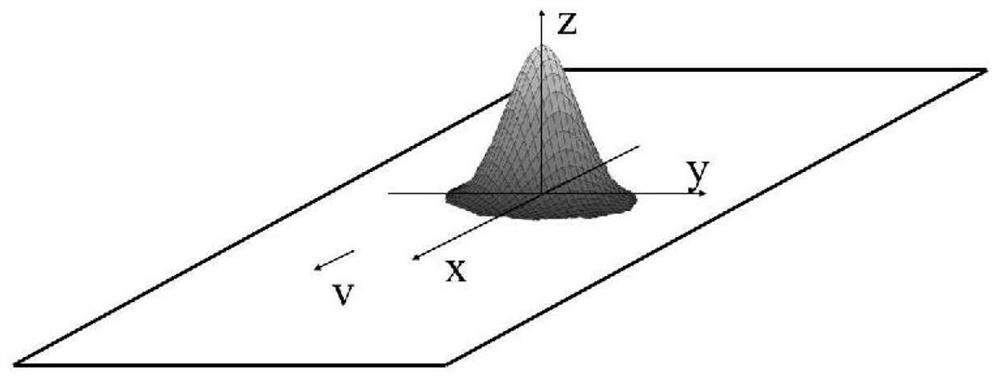

[0076] Taking laser power of 600W, laser scanning speed of 5mm / s, and spot diameter of 3mm as an e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com