Micro-cavity electrode structure and organic light-emitting device

An electroluminescent device and electrode structure technology, which is applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problem that organic electroluminescent diodes cannot effectively improve color shift and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

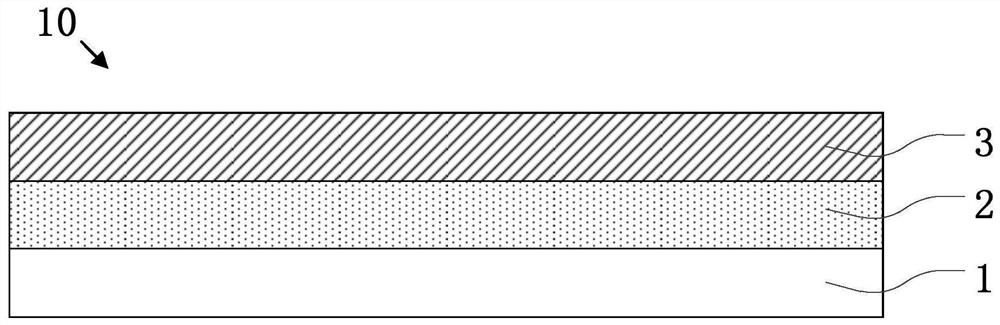

[0033] see figure 1 As shown, a microcavity electrode structure 10 is provided in the first embodiment of the present invention, including a transparent electrode layer 1, a dielectric layer 2 and a non-transparent reflective electrode layer 3; the dielectric layer 2 is arranged on the transparent electrode layer 1; the non-transparent reflective electrode layer 3 is disposed on the dielectric layer 2; wherein, the dielectric layer 2 forms a first Microcavity 110 .

[0034] In this embodiment, the optical length can be adjusted by adjusting the refractive index and thickness of the dielectric layer 2. The purpose of controlling the optical length is to achieve the highest luminous efficiency, achieve the purpose of improving luminous efficiency and control color coordinates, and realize the microcavity effect. Therefore, the dielectric layer 2 forms the first microcavity 110 .

[0035] In this embodiment, the material of the non-transparent reflective electrode layer 3 is a ...

Embodiment 2

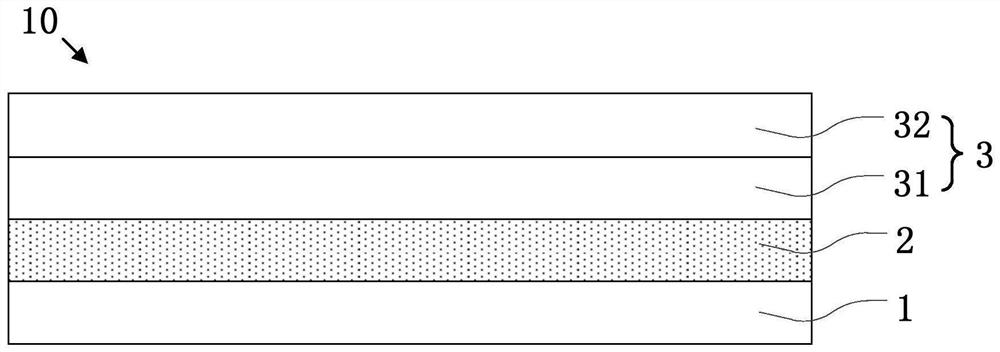

[0038] see figure 2 As shown, the second embodiment includes most of the technical features of the first embodiment, the difference is that the non-transparent reflective electrode layer 3 in the second embodiment has a two-layer structure, including a transparent conductive layer 31 and The metal reflective layer 32, instead of the non-transparent reflective electrode layer 3 in the first embodiment, has a single-layer structure.

[0039] Specifically, in this embodiment, the metal reflective layer 32 is disposed on the transparent conductive layer 31 ; the dielectric layer 2 is disposed on the metal reflective layer 32 .

[0040] In this embodiment, the material of the transparent electrode layer 1 and the transparent conductive layer 31 includes indium tin oxide; the material of the metal reflective layer 32 includes one or more alloys of Ag, Al, Mg or Ti , preferably silver.

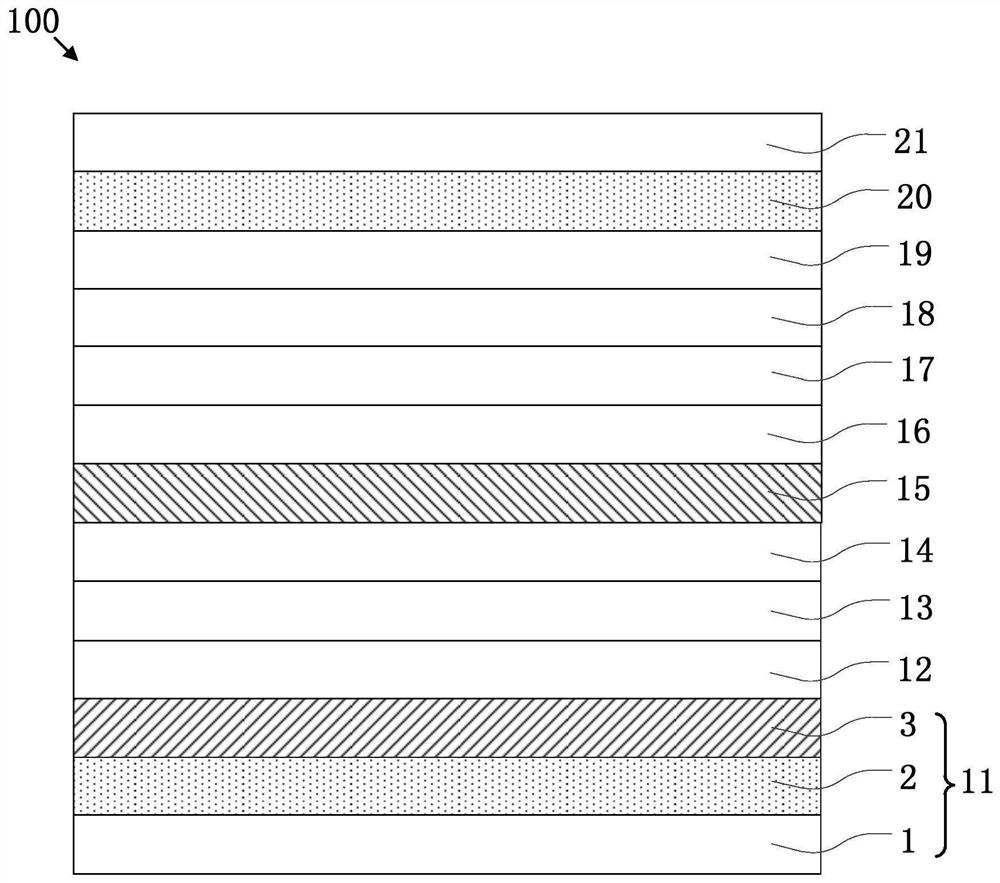

[0041] see image 3 , Figure 4As shown, an organic electroluminescent device 100 is also pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com