A kind of molybdenum-doped porous silicon-carbon composite material and its preparation method and lithium ion battery

A carbon composite material and composite material technology, applied in the field of molybdenum-doped porous silicon-carbon composite material and its preparation method, and lithium-ion batteries, can solve problems affecting the rate and power performance, material conductivity deviation, etc., to avoid structural collapse , improve the binding force and stability, avoid the effect of diving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

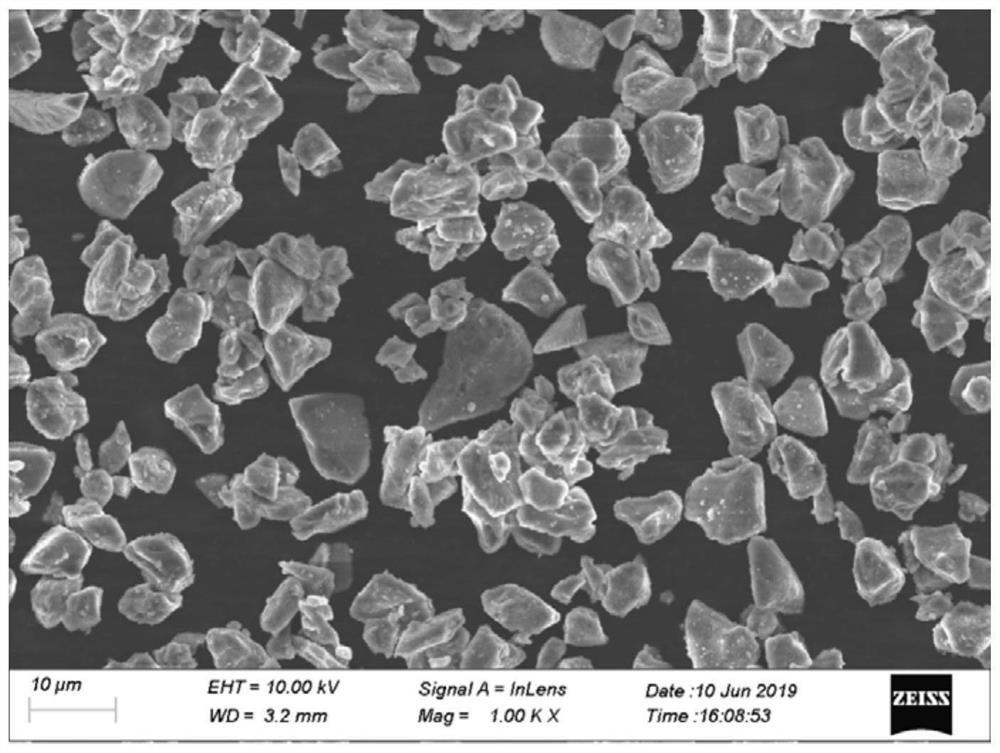

Image

Examples

Embodiment 1

[0062] The invention provides a molybdenum-doped porous silicon-carbon composite material, the molybdenum-doped porous silicon-carbon composite material includes porous nano-silicon, molybdenum oxide, graphene and amorphous carbon, and the molybdenum oxide and nano-silicon are loaded on the on graphene and are connected to graphene through chemical bonds;

[0063] Based on the total mass of the composite material being 100%, the mass percentage of porous nano-silicon is 69%, the mass percentage of molybdenum oxide is 2%, the mass percentage of graphene is 1%, and the amorphous carbon The mass percentage composition is 28%.

[0064] The method comprises the steps of:

[0065] 1) Preparation of the porous nano-silicon material of amination:

[0066] 5g nano silicon is added to 100mL, in the mixed acid solution of 10wt% (the volume ratio of the hydrochloric acid that the preparation mixed acid solution adopts and the sulfuric acid are 1:1, promptly the two are respectively 50mL...

Embodiment 2

[0072] The invention provides a molybdenum-doped porous silicon-carbon composite material, the molybdenum-doped porous silicon-carbon composite material includes porous nano-silicon, molybdenum oxide, graphene and amorphous carbon, and the molybdenum oxide and nano-silicon are loaded on the on graphene and are connected to graphene through chemical bonds;

[0073] Based on the total mass of the composite material as 100%, the mass percentage of porous nano-silicon is 78%, the mass percentage of molybdenum oxide is 1.5%, the mass percentage of graphene is 0.5%, and the amorphous carbon The mass percentage content is 20%.

[0074] The method comprises the steps of:

[0075] 1) Preparation of the porous nano-silicon material of amination:

[0076] Add 1g of nano-silicon to 100mL, and the concentration is in the mixed acid solution of 10wt% (the volume ratio of hydrochloric acid and sulfuric acid used to prepare the mixed acid solution is 1:1, that is, the two are respectively 5...

Embodiment 3

[0082]The invention provides a molybdenum-doped porous silicon-carbon composite material, the molybdenum-doped porous silicon-carbon composite material includes porous nano-silicon, molybdenum oxide, graphene and amorphous carbon, and the molybdenum oxide and nano-silicon are loaded on the on graphene and are connected to graphene through chemical bonds;

[0083] Taking the total mass of the composite material as 100%, the mass percentage of porous nano-silicon is 60%, the mass percentage of molybdenum oxide is 10%, the mass percentage of graphene is 5%, and the amorphous carbon The mass percentage composition is 25%.

[0084] The method comprises the steps of:

[0085] 1) Preparation of the porous nano-silicon material of amination:

[0086] 10g nano-silicon is added to 100mL, and concentration is in the mixed acid solution of 10wt% (the volume ratio of the hydrochloric acid and the sulfuric acid that the preparation mixed acid solution adopts is 1:1, promptly both are resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com