Bronze alloy and sliding parts using the bronze alloy

A technology of bronze alloys and sliding parts, which is applied to rotating parts, shafts and bearings, bearing components, etc. which are resistant to centrifugal force, can solve the problems of not considering wear resistance and ablation resistance, so as to reduce manufacturing costs and industrial utilization. The effect of high value and excellent hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

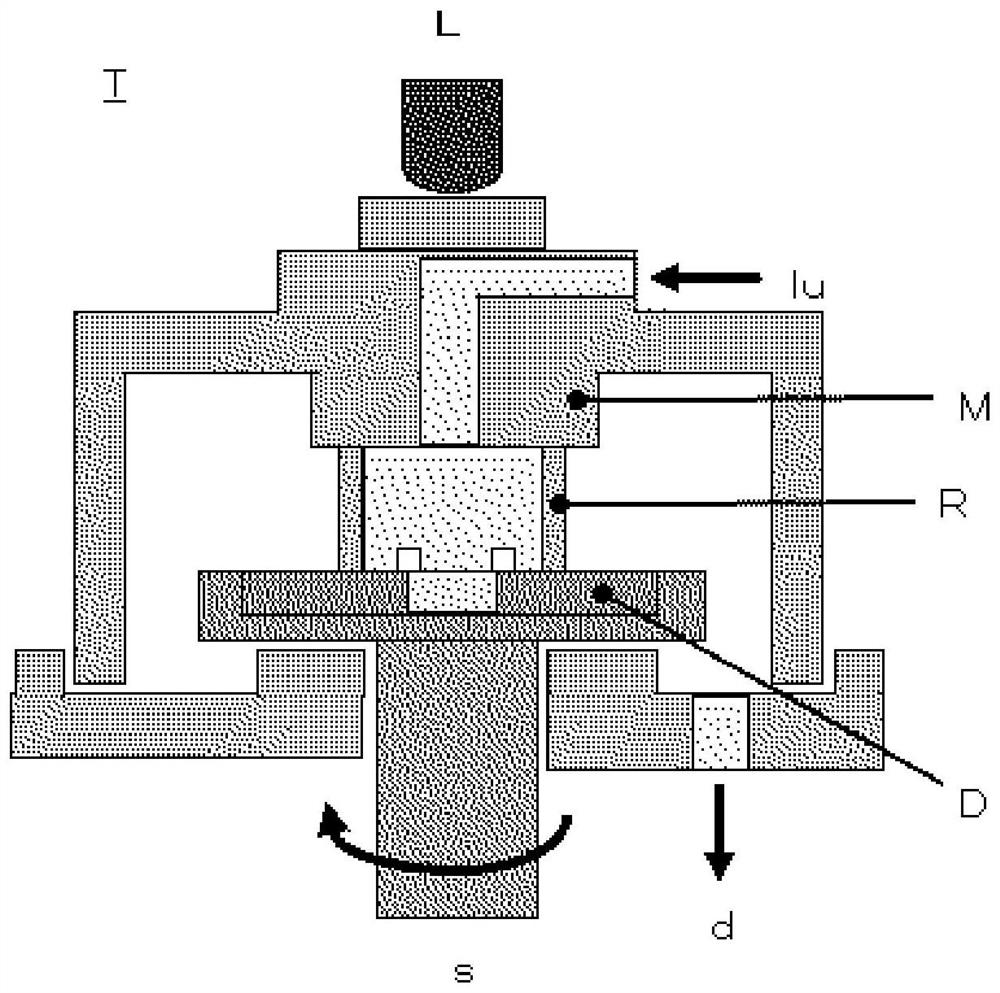

Image

Examples

Embodiment

[0061] Next, specific examples of bronze alloys and sliding members according to the present invention are described based on experimental results.

[0062] Utilize the high-frequency smelting furnace to smelt the bronze alloy with the composition shown in Table 1, after casting the Shell sand mold of the JISA No. tensile test piece, machine it into JIS4 No. tensile test piece, and measure the tensile strength (MPa) of each test piece ), elongation at break (%), Brinell hardness (HB) and crystal grain size of the metal structure.

[0063] [Table 1]

[0064] No. Cu sn Ni Fe Bi S P Pb Zn mn 1 remaining ingredients 11.03 1.47 3.38 1.24 0.36 0.07 0.02 <0.005

Embodiment 5

[0066] In the metal structure of Example 5, Fe precipitates as a compound with Ni, and intermetallic compounds and double sulfides are uniformly dispersed in the metal structure in the form of fine particles. The primary crystal of α-copper becomes finer and becomes a comprehensive fine eutectoid structure. On the other hand, in Comparative Material 1, the primary crystal α-copper grew greatly, forming a heterogeneous metal structure with the eutectoid structure, and the precipitated compound (copper sulfide) was large and scattered randomly. It is clear that by adding Fe and Ni to the lead-free bronze of the present invention in substantially equal amounts, a surprising effect is obtained in terms of homogenization of the metal structure.

[0067] Tensile strength (MPa) and elongation at break (%) were measured in accordance with JIS Z2241, and Brinell hardness was measured in accordance with JIS Z2243, and are shown in Table 2. The determination of the crystal particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com